Ball Screw vs Lead Screw: How to Choose the Right One

By Matt Mowry

Within the world of linear motion, screw-driven actuators are one of the most commonly used devices when converting the rotary motion of a motor (stepper, BLDC, servo, DC) into a linear movement, which is usually guided by a set of linear bearings. More and more often, we are hearing from customers whom are trying to break away from other actuator technologies—in particular air cylinder-driven systems—in favor of the reliability, precision, and ease of use of motorized electrical actuators.

There are two common types of screw-driven systems: Ball screw systems and lead screw systems. Let’s quickly take a look at what may be the better choice for your application.

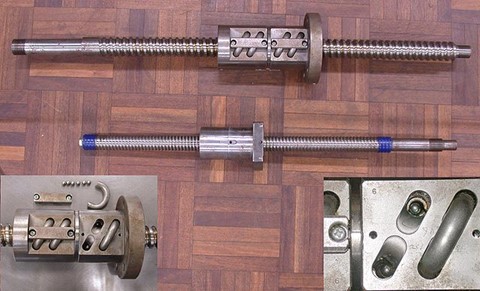

Ball Screws

Ball screws are the right product for applications that have high cycles and continuous motion, and are able to run with higher axial loads than lead screw nuts. They are very similar to recirculating ball bearings since they use the same rolling properties of ball bearings when converting the motion. These ball screws roll inside of special grooves that are cut into the helical outer features of the screw, which allows for lower friction (and thus a smaller motor), higher precision, and again, the ability to run under high-cycle conditions.

Despite these benefits for some applications, ball screws do come with all of the same pitfalls as recirculating ball bearings. The most notable downfall of both ball screws and recirculating ball bearings is their reliance on oil or grease as a lubricant, which requires ongoing maintenance to avoid failures, and can also cause issues in bad environments with dirt, dust, wood shavings, etc. Conversely, the lubrication does not lend itself well to sensitive environments like food processing, packaging, or lab and medical equipment. Due to their low friction and ability to easily be back-driven, they are not always ideal for vertical applications either—where constant motor torque, and maybe even a brake mechanism, may be required to eliminate any chance of the system falling due to gravity—this is often a safety issue. A final note: due to the metal-on-metal nature of ball screw systems, they are much louder than lead screw nuts, which is something to consider for many applications.

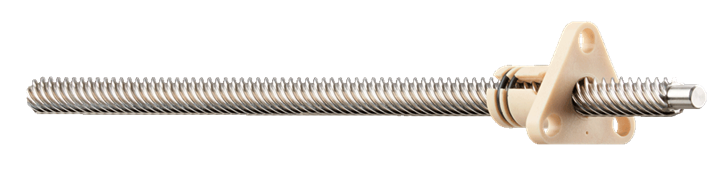

Lead Screw

Generally speaking, lead screws are a more cost-effective system than ball screws, but are only meant for simple positioning functions with low cycles. Often, the lead screw itself is made in the rolling process, and the nuts are made typically of injection molded or machined polymers. These simpler production methods allow for the easy customization of parts, which enables designers to efficiently implement these parts into their projects, even at a low cost. Lead screw nuts can also be 3D printed, and some materials, like those used in the igus® 3D print service, have exceptional tribological properties and are ideal for producing rapid prototypes. Lead screw nuts are available in several geometries including ACME, Trapezoidal (metric ACME), miniature metric thread, as well as high-helix shapes.

ACME and Trapezoidal (sometimes referred to as metric ACME) offer the most threads-per-inch, and are able to be positioned more finitely, especially in hand-powered applications. They are also able to position heavy loads with low torque and do not back-drive, which means they are well suited for vertical applications without the additional expense of a brake mechanism. However, they are not ideal for high speed applications due to the high RPM’s the lead screw would need to spin with in order to move with the fine-pitch leads of the thread. For achieving higher speeds, with lower RPMs, we typically recommend high-helix lead screws.

One potential downside for some applications is the backlash that is present in lead screw nuts. This occurs because lead screw nuts operate under a sliding vs rolling condition where there needs to be extra tolerances to allow for a smooth motion. However, there are options on the market which mitigate the inherent axial clearance of a lead screw system—like the igus® Zero-backlash and pre-loaded nuts. Perhaps one of the most important parts about lead screw nuts, particularly polymer-based nuts, is that they are self-lubricating and work well in nearly every environment without messy lubrication.

To Briefly Recap

When to Choose Ball Screws:

- High loads with high speeds

- Constant Cycling

- High precision

When to Choose Lead Screws:

- Low cost requirements

- Positioning applications

- Applications where lubrication is a detriment

I hope that this helps simplify the process of choosing. We do provide online product-finders to help determine the suitability of a lead screw nut for your next application, as well as a tutorial on how to use it.

For more assistance, please feel free to reach out to our Lead Screw Specialist.