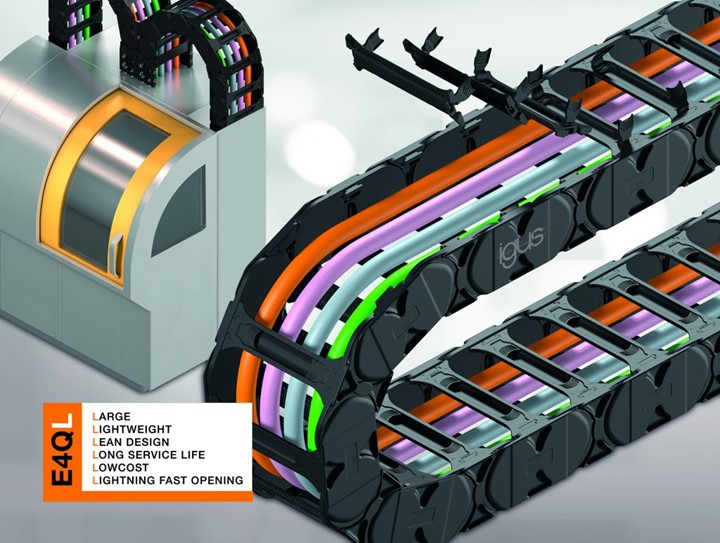

New low-cost e-chain cable carrier from igus for unsupported lengths offers stability with minimal weight

The new E4Q.64L is up to 20 percent more cost-effective than its larger brother E4Q due to biomimetic design

Benefit from the advantages of the E4Q and save up to 20 percent in costs: With its high stability, long service life, and low weight, the new E4Q.64L is impressive for applications with medium loads, for example, in machine tools. (Source: igus GmbH)

07 August 2023 – igus®, the world leader in motion plastics and moving cable management systems, has added a new addition to its cable carrier product portfolio: the E4Q, a globally proven e-chain® for applications with long cantilever lengths and high fill weights, is now available as an “L” version. With the E4Q.64L, users for whom the E4Q was previously oversized can save up to 20 percent in costs. They still benefit from the advantages of the larger brother model – such as the fast, tool-free opening.

From the 7th axis on robots in portal applications to machine tools

In demanding applications with large unsupported lengths and high fill weights, the E4Q series from igus has established itself in recent years for two reasons: On the one hand, the e-chain is particularly robust thanks to its wide side plates and four stop-dogs per chain link. On the other hand, users save up to 40 percent assembly time because the bars can be opened in seconds – without tools and with just two fingers. The problem: In applications with medium loads, the e-chain was often oversized, such as machine tools, woodworking, or car wash systems.

“To be able to offer users the advantages of the E4Q here as well, and at a more affordable price, we have developed the L version E4Q.64L,” says Christian Ziegler, Head of Product Management e-chains at igus. “Depending on the width, the low-cost version of the energy chain is between 15 and 20 percent cheaper than the E4Q.”

Biomimetic design provides low-weight and three stop-dogs per chain link to ensure robustness

To save costs, igus designers have modified the E4Q design. The goal was to strike a balance between weight and strength. The side links on the chain links, which are more narrow than the E4Q, account for the lower weight. The biomimetic design has been retained, which omits material wherever it does not have a supporting function.

“The stop system, however, has been completely rethought. The development goal was more stability and service life than the predecessor models with two stop dogs per chain link. The E4Q.64L is now the first energy chain from igus to have three stop dogs in each chain link,” says Ziegler. “This ensures an even more uniform force flow and extended service life.”

Up to 20 percent more unsupported length

Tests in the igus test lab prove that compared to the 14240 series, also used for unsupported applications, the E4Q.64L has an approximately 30 percent higher breaking moment. This results in up to 20 percent more length with the same fill weight. With 4kg/m, for example, the E4Q.64L achieves 3.2 meters. With the predecessor models E4/Light and E4.1, it is 2.7 meters.

Ziegler continued, “Thanks to the outstanding stability of the E4Q.64L, we can now serve many applications, such as passenger boarding bridges at airports or car washes more cost-effectively than ever before.”

There is sufficient space for energy and data lines due to the optimized internal and external dimensions ratio. The E4Q.64L has an interior height of 64 mm. In addition, by replacing the outer bracket with a special RBR bracket, the e-chain can also be operated in two bending directions. Thus, The chain has a so-called reverse bend radius (RBR), which allows circular movements to be realized on axis 1 of a robot.

Adaptable like a chameleon: Widths between 100 and 500 millimeters available

The new E4Q.64L energy chain from igus retains the same intuitive opening mechanism as the larger E4Q model, making it just as easy to open and access. The opening bars have molded recesses that allow users to unlock the end hooks with two fingers. Once unlocked at both ends, the bars can be removed upward with minimal effort. This familiar design ensures a smooth transition for users of the E4Q.

Additionally, the E4Q.64L launches with an extensive range of 29 available bar widths, ranging from 100 to 500 millimeters. This wide range allows the E4Q.64L to be customized for many applications immediately. Overall, the E4Q.64L provides the same ease of use and customizability as the proven E4Q design in a more compact and affordable package.