New igus xiros ball bearing materials stand up to chemicals and temperatures of 150°C

More reliability in the chemical and semiconductor industries with the xirodur F500 cage material or zirconium oxide balls

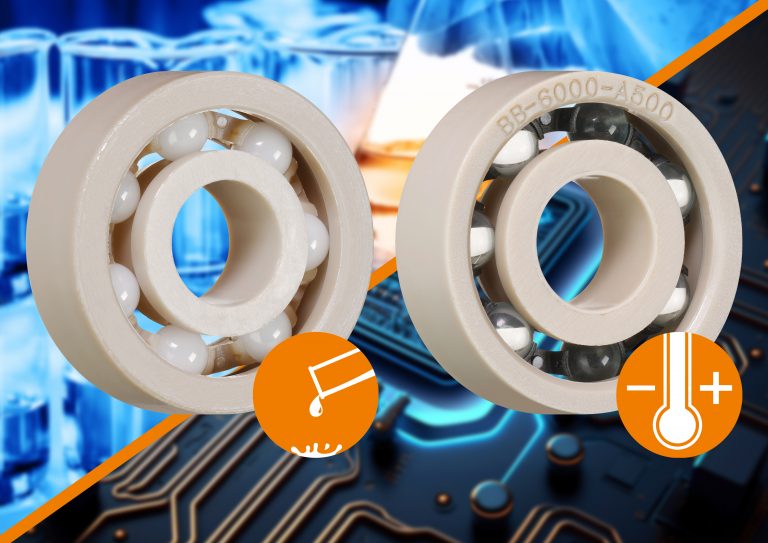

The new igus cage and ball materials for the high-temperature range allow for longer maintenance cycles and greater reliability in the chemical and semiconductor industries. (Source: igus, Inc.)

1 June 2023 – igus®, the Germany-based manufacturer of motion plastics, announced it is adding two new materials to its range of ball bearings for high-temperature use.

Machines and systems have to withstand temperatures above 200°F and aggressive chemicals. For more machine reliability and less maintenance, igus has developed the dry-running xiros® A500 deep groove ball bearing specifically for chemical and temperature resistance. Users now also have access to the xirodur® F500 cage material and balls made of zirconium oxide.

Heat and highly aggressive chemicals in multi-shift operation: conditions in the chemical and semiconductor industries lead to frequent replacement of such machine components as ball bearings. The risk of material failure, which leads to expensive system downtimes, is always present.

“Increasing customer requests for a particularly durable solution have prompted us to use new materials for our proven xiros A500 polymer ball bearing. For example, they withstand the special requirements of the chemical industry and of semiconductor and battery production in the automotive industry,” says Marcus Semsroth, Head of Business Unit xiros Polymer Ball Bearings at igus. “That’s why we now offer customers even more options when looking for the right cage or ball material for their application.”

Ceramic balls – extremely robust and resistant to thermal shock

igus deep groove ball bearings are constructed with inner and outer rings made of tried-and-tested xirodur A500 high-performance plastic. In addition to stainless steel and glass balls, igus now offers ceramic balls made of zirconium oxide – also known as ceramic steel. The advantage of ceramic balls is that they are almost indestructible. They are characterized by outstanding strength, high breaking resistance, and low abrasion. They also feature high thermal shock resistance.

New F500 cage material with 50% longer service life

“We have also developed a new high-temperature cage material: xirodur F500. It was based on our iglidur® J3 cage material, which was developed for standard temperatures and has already proven its wear resistance,” says Semsroth.

The F500 cage not only allows the self-lubricating ball bearings to stand up to continuous temperatures of 302°F (150°C) but also makes them resistant to many chemicals. That is not all, however: the xiros ball bearings are put through their paces on various test rigs in the in-house igus laboratory. Tests show that the reinforced xirodur F500 cage material achieves up to 50% longer service life than comparable A500 ball-bearing cages.

Since xiros ball bearings are made of high-performance plastics, they are also up to 50% lighter than conventional stainless-steel ball bearings. Solid lubricants integrated into the polymers allow for hygienic, low-friction dry operation without maintenance or a single drop of lubricating oil.

“The A500 ball bearing with ceramic balls or the new cage gives users an ideal bearing solution that works reliably even in aggressive and hot environments in the chemical and semiconductor industries. Users benefit from much longer maintenance cycles and greater reliability,” says Semsroth.

Users can quickly find the perfect ball bearing for their application using the igus online xiros service life calculator.