Why is cable shielding necessary?

By Jan Arnoldy

In this blog post, you’ll discover why a cable needs a shield and what appropriate shielding looks like for cables in linear and torsional applications.

Why does a cable need a shield?

The cable’s shield serves as electromagnetic compatibility protection. It prevents interfering signals from the inside of the cable from reaching the outside and disturbing other cables or even electrical devices. Furthermore, the shield ensures that external interference does not reach the inside of the cable.

What is electromagnetic compatibility protection?

Electromagnetic compatibility, or EMC, “is the ability of electrical equipment and systems to function acceptably in their electromagnetic environment, by limiting the unintentional generation, propagation and reception of electromagnetic energy which may cause unwanted effects such as electromagnetic interference (EMI) or even physical damage in operational equipment” (Source). To ensure this protection, a cable must be electrically shielded. This protective effect is expressed strongly by the indication of the optical coverage of the shield. This is the area of the cable that is optically covered by the shield.

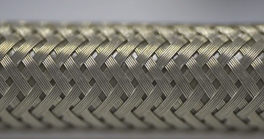

For example, if the cable has foil as its shield, it can be said to have 100% coverage. The optical coverage of our chainflex® cables can reach a value of 90% due to a shield consisting of tinned copper wires.

What do you have to pay attention to when using a shield?

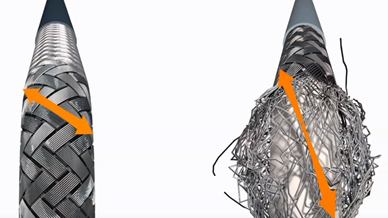

A shield with braid angles that are too acute or the use of foil shielding can often lead to error patterns such as shield breakage. To ensure that these faults do not occur, our shielded chainflex® cables use either braided or wrapped shielding, depending on the type of application.

It is important for cables in linear applications to have a braided shield with a particularly flat braid angle. That’s because the electromagnetic compatibility protection works consistently well during movement due to a shielding window that opens minimally in the radius.

Cable shields for linear vs. torsional applications

The cable shielding should always be selected according to the type of application. With our chainflex® cables, we distinguish between cables for linear applications in an e-chain® cable carrier and torsional applications such as on robots.

For linear movement, we use the braided shielding that’s described above (pictured right).

For cables used in torsional applications, we use a shield wrap if possible (pictured left). Here the copper wires of the shield are not braided but wrapped in one direction. Optically, this is comparable to a spiral that wraps itself around the inner part of the cable.

In this way, a high shield coverage can also be ensured in a torsional application, as the shield can open and close in motion.

To learn more about chainflex® cables, visit this webpage or contact igus® here with any questions.