How to Manage Lateral Movement on Long-Travel Energy Chains

By Stephen Bowman

Long Travel Applications

Bulk Handling and Mining and other heavy duty applications require us to pay particular attention to every detail during the design of a dynamic cable management system. There are many harsh conditions that cable management systems need to endure everyday without failure.

These include corrosive and abrasive materials like coal, taconite, sand and gravel, long travel distances in the range of thousands of feet of travel, vibrations from surrounding equipment, and snow and ice accumulation. Anything less than “heavy duty” ends up in the trash bin. Today, I would like to discuss one factor that is easily overlooked when designing the proper dynamic cable management system: lateral deviation of the moving structure relative to the rails of the system, or in other words, moving left and right while going straight.

To understand why lateral deviation is important, I will first briefly describe long travel gliding applications.

Chains that Glide

The two common configurations of energy chain systems are unsupported short travel and long travel gliding. Unsupported short travel is just what is sounds like — the travel is short, usually under 30 feet, and the cable management system requires no support. It is strong enough to support itself and the fill weight for a specified travel distance. Every cable carrier has a maximum amount of unsupported travel distance relative to its fill weight. Moving past this limit will require a larger, stronger cable carrier or utilizing a configuration called “long travel gliding.” This configuration is commonly used in Bulk Handling and Mining applications with a travel distance ranging from 30 feet up to a few thousand feet.

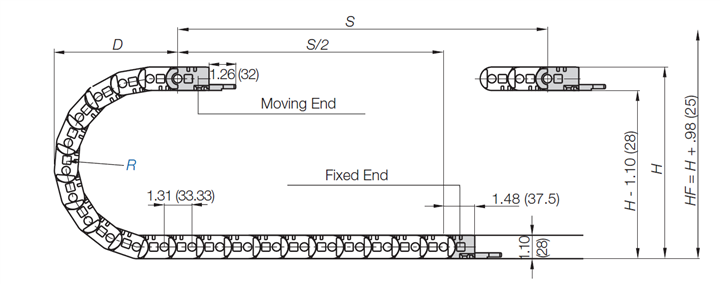

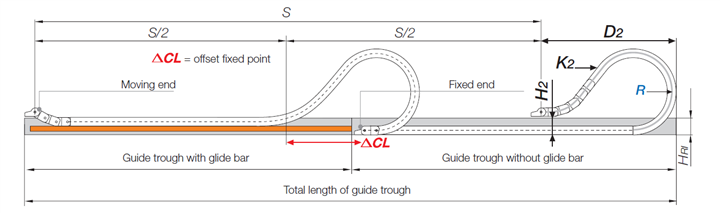

At igus®, we call them long travel gliding because the e-chain® cable carrier glides on top of itself inside a trough system. The trough system keeps the upper run of the cable carrier perfectly aligned with the lower run of the cable carrier. There is a fixed end and a moving end of the cable carrier. The fixed end is usually in the center of travel, but not always, and the moving end is attached to the moving structure. The trough system is installed parallel with the rails of the moving structure. In a perfect world, the moving structure follows the rails and the trough system without deviation.

The Problem

We don’t live in a perfect world. Sometimes we think of a rail mounted moving structure as perfect, but all rail mounted moving structures will have some degree of lateral deviation that can arise from various contributing factors. The tread of a trolley wheel could be wider than the rail width allowing for lateral movement. The fixed structure could deflect under the load of the moving structure. The moving structure may not be perfectly square. The rails may not be straight or parallel with each other. All these factors affect the total amount of lateral deviation. Now what do we do?

Energy chain systems have a specific amount of lateral deviation allowed based on the series of energy chain. If the lateral deviation of the moving structure is greater than this allowance, the energy chain will push against the sides of the trough system creating wear points, metal fatigue, and potentially snagging on the trough system. A Floating Tow Arm (FTA) is vital component needed to compensate for this lateral deviation.

The Floating Tow Arm

An FTA is a specialized igus® component incorporating a linear bearing sandwiched between an upper and lower assembly. The lower assembly attaches to the moving end of the igus energy chain and the upper assembly attaches to the tow arm of the moving structure. The linear bearing allows for the lateral deviation of the moving structure and the igus trough system.

igus® has three categories of FTA’s each designed for various applications: Basic, Standard, and HD (Heavy Duty). The Standard and HD versions incorporate a supporting drive plate and wheels in the lower assembly that track inside the trough system keeping the upper run of the energy chain aligned with the lower run. The Basic version does not re quire wheels as they are designed for lower duty smaller energy chain applications. Each version also has a maximum force measured in Newtons that assists us in selecting the right FTA for your application.

Check out this video to see how a Floating Tow Arm works (no sound):

https://www.youtube.com/embed/Qn0xxCe6SYM The amount of lateral deviation for our three FTA versions are shown below. If your lateral deviation falls outside these standards, we can also help consult and design a Floating Tow Arm that fits your application.

- Basic FTA:

+/- 25mm or just under +/- 1 inch - Standard FTA:

+/- 35mm or just under +/- 1-3/8 inch - HD FTA:

+/- 30mm or just under +/- 1-1/8 inch

Whether your application is in a coal facility, on a grain ship loader, or on a crane, we can confidently select the correct FTA for your application and confirm your system will work everyday without failure.

If you would like to know more about igus® Floating Tow Arms, you can contact us at 1-800-965-2496 or visit https://www.igus.ca/info/bulk-material-handling-equipment. And remember, our design services are always free!