Tagged: lead screw systems

Pre-assembled linear slide tables from igus® are designed to save engineering time and resources. They are also flexible enough to meet the demands of a wide range of applications. The two most common types...

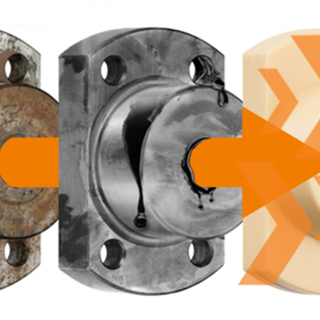

By igu-blog-adm (Edited by Kevin Wright and Shizu Yamaguchi) Customers often ask: “Can I use WD-40 or another lubricant to grease my polymer bearings?” Is external lubrication necessary or advantageous for igus® polymers? We...

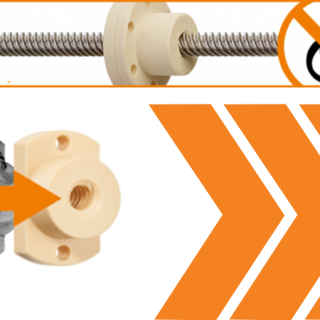

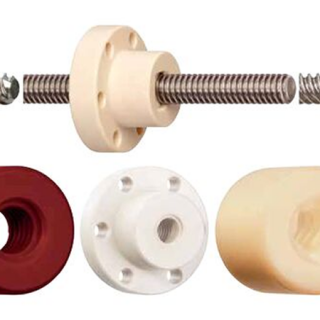

By Zoe Moser (Edited by Kevin Wright and Shizu Yamaguchi) Our lead screw support blocks are available in thread sizes of 6-24 mm with options for trapezoidal, dryspin high helix and metric threads (Acme...

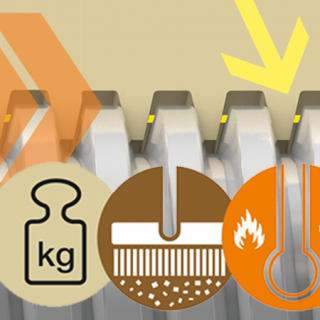

By Zoe Moser (Edited by Kevin Wright) Lead screw drives are used in a wide variety of industries and applications: from automation machines, to robotics, to material handling. Demands on lead screw drives can...

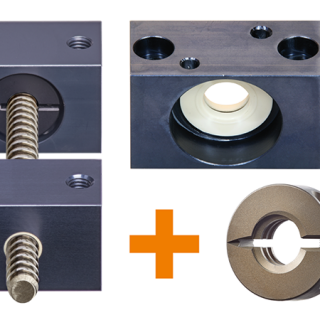

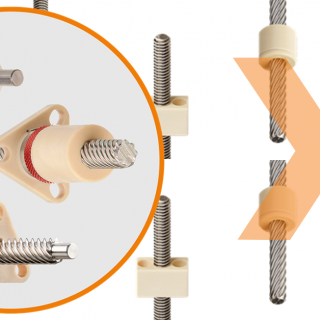

By Zoe Moser What is axial clearance? What should we watch out for? And what possibilities does igus offer for reducing axial clearance? The question of clearance is often asked when dealing with lead...

By Zoe Moser Even though our plastic components don’t require any external lubricants, people still want to know if they can use WD-40 or another lubricant on them. This article is intended to emphasize...

By Matt Mowry Within the world of linear motion, screw-driven actuators are one of the most commonly used devices when converting the rotary motion of a motor (stepper, BLDC, servo, DC) into a linear...

One of the most common lead screw geometries in North American manufacturing is the ACME lead screw system. Designed with a trapezoidal shape, a flank angle of 29 degrees and a higher pitch than fastening...