The 3 Advantages of Assembled Cables

Every moving application requires continuous-flex cables, but why waste time assembling them when you don’t have to? The readycable® line of assembled motor, servo, signal and encoder cables comes equipped with standard industrial connectors that are ready to plug into your application the second they arrive. They are expertly built similar to 24 manufacturer standards and are continuously tested under real-world conditions in the 41,000-square-foot igus® test lab.

Our tests ensure each cable provides an extensive service life inside cable carriers, on robotic applications and more.

Read on to learn more about the three advantages of readycable®.

Cable assembly with quality assurance

At 12 state-of-the-art facilities throughout the world, including the U.S., highly-skilled technicians customize approximately 20,000 ready-to-connect chainflex® cables every week. All of the cables are assembled similar to 24 manufacturer standards, including Siemens, Allen Bradley and FANUC, and come equipped with industrial connectors from the biggest names in the industry, such as Intercontec, Harting and Yamaichi. Plus, igus® has created a new ibow® angle adapter that safely secures cable connections at a 90-degree angle.

The three advantages of assembled cables

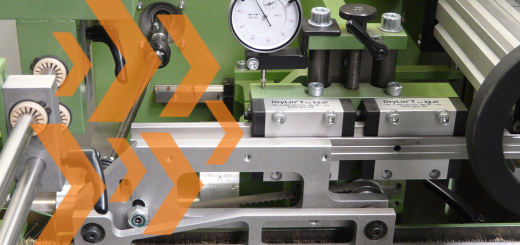

Our technicians electrically test every cable, visually inspect every connection, and measure crimp heights and all critical dimensions precisely to ensure our assembled cables will function perfectly upon delivery and every day during the life of your machine. More than 1,200 cable types are available for customization.

Cable design features for an extended service life

Unlike traditional cables, chainflex® continuous-flex cables are engineered for optimal efficiency and can dramatically increase the service life and productivity of dynamic applications. The following design features enable chainflex® to outperform other cables that tend to fail prematurely:

1. A high-quality, high-tensile strength center element for strain relief

2. A medium-to-fine conductor strand diameter to prevent the strand from kinking while being subjected to a high number of cycles

3. The highest quality high-pressure extruded PVC or TPE materials that support the individual strands of the conductor and prevent the cable’s insulation from adhering to one another

4. Individual conductors bundled into groups, which are cabled together in a single layer surrounding the cable core, that enable pulling and compressive forces in the bending motion to balance and cancel out torsional forces

5. A pressure-extruded inner jacket that ensures the insulated conductors are guided efficiently

6. A high-quality braided shield that provides electromagnetic interference (EMI) protection for the cable

7. A cost-effective outer jacket material that is resistant to UV radiation, abrasion, oils and chemicals

8. CFRIP technology that allows users to open the cables’ jackets like a zipper, saving you time and eliminating the need for additional tools

Extensively tested under real-world conditions

Unfortunately for consumers, there are no standardized testing procedures for continuous-flex cables; therefore, it is important to know how a manufacturer tests its products. Ideally, these cables should be tested in configurations and environments that replicate real-world applications.