An affordable autonomous surface vehicle using plastic bearings

By Jared Worth

When Damon and Jillaire McMillan founded Blue Trail Engineering in 2019, they set out to develop waterproof products that don’t require large “military-sized” budgets or corporate expense accounts. Damon discovered this market opportunity during the development of his solar-powered robotic boat, the SeaCharger.

Damon McMillan & family with the SeaCharger (Photo courtesy of Blue Trail Engineering)

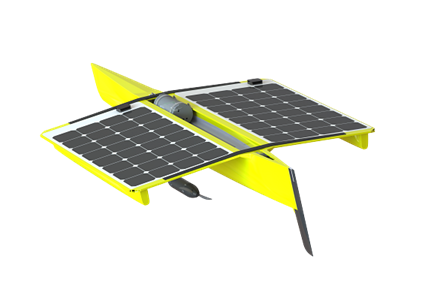

McMillan has been working to develop “a much more capable solar-powered autonomous boat”, which is being dubbed the Blue Traveler. “Although we may need to change the name to avoid a lawsuit from Blues Traveler, the band,” Damon McMillan quipped. The current plan for the Blue Traveler is for it to sail for up to a year on the open ocean while carrying various environmental monitoring sensors and other payloads.

Finding an alternative to metal & ceramic components

One of the main design challenges encountered with Blue Traveler had to do with bearing selection.

“Since Blue Traveler will be a small ocean-going boat, about 8 feet long, every part of it will be continuously splashed by seawater. This is the main challenge. Seawater will rapidly destroy traditional bearings such as ball bearings — even ones made of stainless steel — and bronze bushings,” said McMillan.

With metal bearings out of the question, plastic and ceramic bearings were both considered. While ceramic bearings did meet the requirements of the system — capable of withstanding contaminated seawater while maintaining a low rate of wear — ultimately they were too expensive for what McMillan was hoping to achieve.

Making ocean research affordable

Since McMillan intended for Blue Traveler to be a solution for researchers and smaller companies, he needed to keep costs as low as possible to remain affordable for these groups.

“Whereas most other autonomous ocean-going boats are geared towards the military market, the low cost of Blue Traveler will make it perfect for applications such as environmental monitoring that don’t always have a military-sized budget,” said McMillan.

McMillan anticipated Blue Traveler to cost about $15,000; less than one tenth the cost of similarly-sized autonomous boats, which can cost as much as $500,000.

Rendering of Blue Traveler (Photo courtesy of Blue Trail Engineering)

Plastic bearings for millions of movements

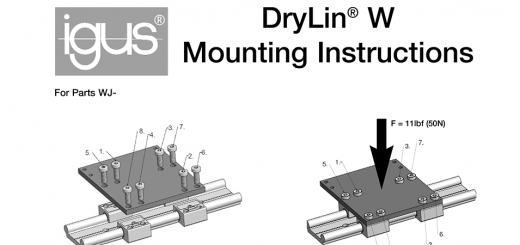

This led McMillan to use plastic bearings from igus® for Blue Traveler. Plain bearings and spherical bearings were used for the rudder pivot point and rudder control linkage respectively.

Both the plain and spherical bearings used meet the extensive service life requirements of Blue Traveler, even with frequent exposure to seawater.

“On the average, the rudder will move two times per second. Over the course of a year, that equals about 60,000,000 movements,” explained McMillan.

A plain bearing was also used inside the thruster motor as a spacer. According to McMillan, “This is a dry location, so it doesn’t have the same environmental requirements, but we use [a plastic bearing] because it is the most cost-effective solution we could find.”

While McMillan has already found success with igus’ bearings, he plans to contact them in the near future to find the perfect bearing material to fully optimize Blue Traveler’s performance.

To view other igus solutions for the marine industry, check out our webpage. For questions about your own application, contact an expert!