6 Most Common Causes of Cable Failure

By Don Nester

Cable failure can result in a waste of resources as well as time and effort applied to replacing the failed cables. This issue is one of the leading causes of downtime, resulting in an oftentimes considerable loss of production and therefore revenue. In order to prevent these issues, it’s helpful to better understand typical reasons why they occur.

Below we’ve compiled the 6 most common types of cable failure design that engineers should be on the lookout for.

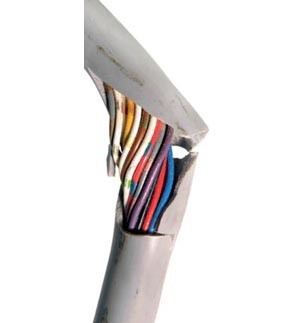

1) Loss of continuity

If the cable core cannot absorb its mechanical load while flexing, the force gets transferred onto the copper conductors, which causes them to break under the increased tensile load. Alternatively, if insulated conductors are twisted with an incorrect pitch length or pitch direction, copper conductors can sever and break. Both situations are examples of a loss of continuity.

2) Insulation damage

Insulation damage occurs when the insulation integrity of the conductors is compromised or gets perforated. This is caused by material fatigue due to constant bending stress, abrasion within the cable structure and/or conductor strand breakage.

3) Corkscrewing

This failure is easily recognizable by the mechanical deformation of the entire cable. The corkscrew or “pigtail” effect occurs when torsional forces are released during operation due to incorrect cable configuration, pitch length and pitch direction. Cables that are constructed in layers rather than bundled are more susceptible to corkscrewing.

4) Jacket abrasion

Jacket abrasion occurs when the outer jacket of a cable wears through to the underlying layer of conductors or shielding. This failure is especially common when using cables with soft jackets. However, this problem can also be caused by a thin wall-thickness that can develop during the jacket extrusion process.

5) Jacket swelling/cracking

The outer jacket of a cable swells when it has been exposed to oils or chemicals it was not designed to withstand. Jacket cracking occurs when the jacket breaks and deteriorates down to the cable’s shield, normally as a result of excessively high or low temperatures.

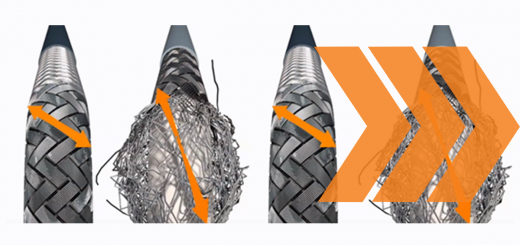

6) Shielding losses/EMC problems

Increased electromagnetic interference (EMI) occurs when the shield, which is designed to protect cable signals from electromagnetic fields, breaks and develops abrasions due to continuous bending.

Understanding these 6 cable failure types is essential to minimizing unexpected production downtime. Recognizing these issues at the beginning of the buying process increases the likelihood that you will purchase the most optimal cable for your automated application. This will ultimately ensure that you will get the most efficient production possible, which will save you money and time in the long-run.

If you’d like to learn more about chainflex® flexible cables made by igus®, visit our site here.