How to Calculate Surface Pressure for Plain Bearings

By Lars Butenschon

Surface pressure is one of the most important factors for figuring out the right plain bearing for your application. In this post, I will show you how you can quickly and easily calculate the surface pressure for your bearing.

It starts with the surface, not the pressure!

Snowshoes use a relatively large area to distribute the weight of their hiker on loose snow or muddy ground. Because of this weight distribution, the hiker does not sink deeply into the ground. This situation is similar to that of plain bearings. A bearing’s surface pressure depends on how many bearings are being used to bear the weight of a given force. The more bearings, just like the larger the area of a snowshoe, the lesser the surface pressure per bearing. Often the surface over which loads are distributed are not taken into account when calculating surface pressure.

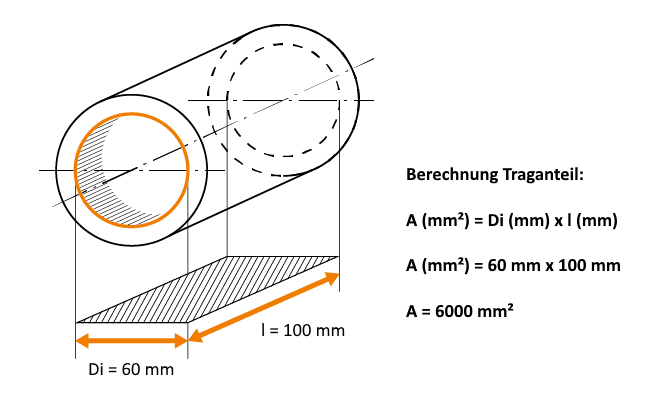

To perform the surface calculation – or more precisely, the calculation of the bearing area of the surface – of a plain bearing, we calculate as follows:

Calculation of the load bearing ratio of a sleeve bearing (Source: igus GmbH)

A (mm²) = Inner diameter (mm) x bearing length (mm)

This figure does not correspond to the exact inner surface of the plain bearing. Because of its cylindrical shape, the contact area would actually be larger in real life. Also, in the real world, not every part inside the bearing would bear the same load. However, this calculation using bearing length and diameter is ultimately simple and more practical.

Especially with plain plastic bearings, it is important that the load it carries is distributed over as large an area as possible, given that its compressive strength is lower than that of steel. This subject is beyond the scope of this blog post.

What else do we need to calculate the surface pressure? The pressure!

The unit for surface pressure is N/mm². So what we are still missing is the N. That N stands for Newton and is not exactly the same as weight. In practice, the weight that presses upon a given bearing is often converted by a factor of 10. That factor would more accurately translate to 9.81, for the mean acceleration due to gravity.

Meaning:

Correct: Force (N) = Weight (kg) x 9. 81

Practice: Force (N) = Weight (kg) x 10 = “Fits with adequate clearance”

A load on the bearing surface will result in Newton (N) and can now be used in relation to the bearing surface.

Calculate surface pressure: p = F / A

The force just calculated is distributed over the bearing surface. From here, we can divide the force by the calculated surface area to obtain the surface pressure. Many other aspects of plain bearing design are linked to this calculation. Edge loads and the resulting bearing damage, the effects of reduced wall thickness and the PV value and its pitfalls – to name just a few aspects, also have a very large influence on the running performance and the suitability of a plain bearing.

Contact a product expert today!

Whether you need support in designing your application with plain bearings or are still in the early stages of design, we can provide consultation by phone at 1-800-965-2496, Livechat, virtual visit or at our headquarters. Together we can find the most cost-effective solution that works.