The 3 Most Common Misconceptions About Plastic Bearings

By Lars Butenschon

Plastics have become an integral part of our lives and the industries we work in. We are increasingly aware that there is no such thing as one superior plastic material just as there is no one superior metallic material. Plastics have been applied in applications requiring lighter and more economical solutions and have expanded our vision of what we see as possible. In spite of all these developments with polymers, people still hold certain misconceptions about the material. In this article, I will shed some light on these ideas as well as dispel what are mistaken about them.

Error #1: Plastic plain bearings are simply too soft

That plastics are “softer” than metal seems obvious. Compressive strength and surface hardness values are significantly lower in plastics compared to metal. Plastic plain bearings are also considered less durable than metal.

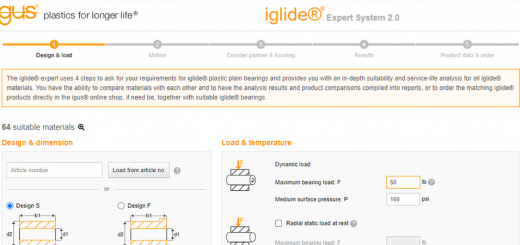

Examine, however, a plain bearing within its actual application. How high is the load on the plain bearing? What is the total load on the one bearing? And what is the surface pressure on the bearing? It often turns out that the surface pressure, i.e. the load distributed over the bearing surface of the plain bearing, may not be as large as one might assume. And even if there is a fairly large load, a simple plastic plain bearing of 20 x 20mm size easily bear the weight of a small vehicle (30MPa surface pressure at a weight of approx. 1,200kg).

Another factor to consider in comparing plastics to their metal counterparts is lubrication. For moving applications, plain bearings can often contain dry lubrication, which prevents the requirement for additional greasing. Metal bearings, on the other hand, require additional lubrication. Also, dry-operating metal bearings only function with polymer inlays. And these carry with them the same disadvantages as plain bearings entirely made of polymer.

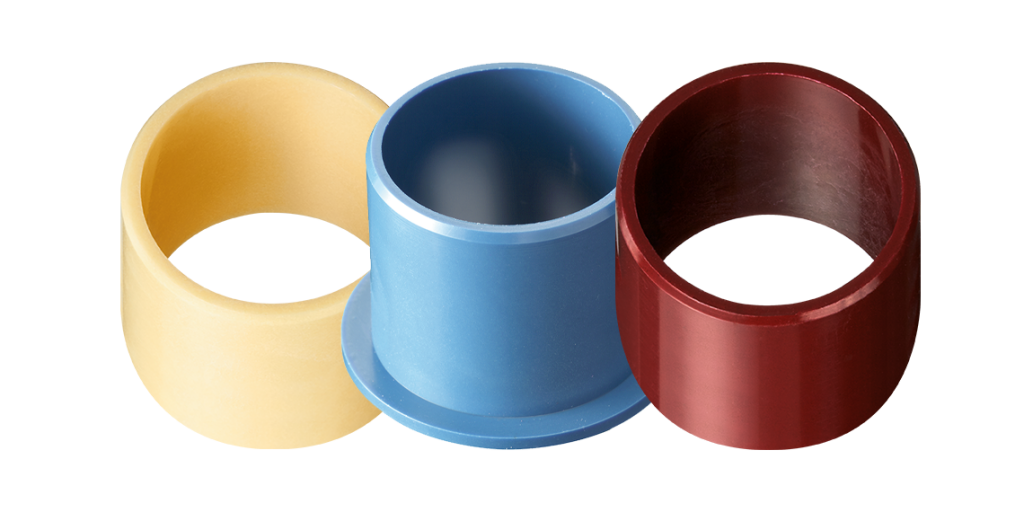

Error #2: Polymer plain bearings have more clearance and they rattle

Yes, plain bearings made of polymer require more clearance than ball bearings, for example. The principles of how these bearings each function however, are different, so a mere comparison of clearance is misleading. Whereas ball and rolling bearings operate with rolling friction, plain bearings operate on the principle of sliding friction. In order for the sliding movement to work, the shaft and bearing must be able to move against each other and so clearance must be increased. In addition, because polymers expand under heat and moisture, additional clearance must be calculated in to account for these elements. (Expansion varies greatly with the type of polymer material. Polymers with lower thermal expansion and low moisture absorption can be used even with very little bearing clearance).

As for rattling, noise level can actually be improved by using polymer plain bearings. If the right polymer is used, vibration dampening can be better than the level achieved by metals. It is important to take a close look at the context of the application.

Error #3: Polymer plain bearings don’t last

Polymer plain bearings can have a very long service life (on the order of over 7 million hours). Their service life depends on application details such as load and rotations per minute. Metal bearings, on the other hand, may “die” prematurely, due to lack of maintenance or insufficient greasing. In other words, the durability of plastics versus metals really depends on more than just the material type.

Conclusion: The right material for YOUR application is what counts

Just as there is not only one choice for metal plain bearings, there is not only one choice for polymer plain bearings. Choosing can be challenging. Hopefully dispelling some of the myths around plastics in this article has been helpful to in your selection process. Best of luck.