How to Measure Bearings

By Shizu Yamaguchi

Whether you are looking to replace an old bearing or seek out extras to have on hand, knowing how to measure your bearings beforehand is important and can save you some hassle. This article will describe how to measure both metal ball bearings as well as plain plastic bearings, both of which are to be approached differently. Let’s start with plain plastic bearings.

How to measure plastic plain bearings:

Too often, a newly ordered plastic bearing is measured right out of the box using a calipers. When the dimensions do not match catalogue values, the bearings are returned but the issue would not have been with the sizing. Plastic plain bearings are simply measured differently than their metal counterparts.

A few considerations need to be taken into account when measuring plastic bearings:

First, plastic plain bearings do not lend themselves well to measuring using calipers. Because plastic is soft, if calipers are used, the jaws can press themselves into the material, compress it and create more than one measure.

Second, plastic plain bearings are made slightly oversized (ID and OD) because they are designed to be pressfit. Only after being arbor pressed into its final shape will a plastic bearing be properly ready to be measured. Click here for installation instructions.

A pin-gauge test is what igus uses to measure its bearings. In a pin-gauge test, a pin that parallels the size of the intended shaft is inserted through the top of the pressfit bearing. If it falls through the bearing by virtue of its own weight, it’s a “go”. If the pin sticks or fails to fall through the bearing, it’s a “no-go”.

What matters most with a plastic shaft is whether the shaft can fit through the bearing. Minor variations in the width of the bearing, ie, the peaks and valleys of the inner diameter of the bearing are relatively unimportant because these will eventually smooth out due to the gradual release of embedded lubrication.

How to measure a metal bearing:

The best way to find out the size of a given metal ball bearing is to find a reference number on the bearing itself. Usually this number is engraved or laser stamped into the bearing. However, if the number has been rubbed off, the following method can be used to find measurements.

Measuring a metal bearing can be done with vernier calipers. Calipers are measuring instruments made of two long, thin metal pieces adjoined together. Though less accurate, a steel ruler can be used if calipers are not available.

Photo: “Digital calipers” by Dvortygirl, licensed under CC BY-SA 3.0

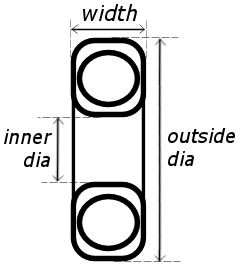

The three lengths measured to determine a metal bearing’s dimensions are inner diameter (ID), outer diameter (OD) and width (W), as shown in the image below.

Fig. 1. “bearing_measure_guide.jpb”; Bearing Boys, 17 February 2021, https://www.bearingboys.co.uk/Measuring-Bearings-15-a#:~:text=It%20is%20sometimes%20necessary%20to,diameter%20and%20an%20outside%20diameter; photograph.

To measure the ID, place the outer anvils of the caliper against the inside bore. The fit does not need to be tight to be accurate. Read the value from the caliper.

To measure the OD, put the jaws of the caliper around the outside of the bearing. Ensure a good fit and read the value.

To measure the width, apply the same method using the jaws of the caliper, as described above, to read the OD.

Note that bearings can be in imperial or metric sizes. Usually metric sizes are in full millimeters, that is, if you see a measurement that is a half millimeter, the likelihood is that that bearing is actually in inch sizing.

Additional metal bearing info:

Further markings on the bearing can assist with further specifying what qualities the bearing replacement should have, if this is a primary reason for measuring the bearing.

“ZZ or 2Z = 2 Metal Shields

2RS1 or 2RSR or DDU= 2 Rubber Seals” (Bearing Boys, 2021).

Additional markings will indicate a clearance value, indicating the room between bearing races for expansion, adding an amount of play.

Here are the markings to reference for this information:

“C2 = Clearance is less than international standard

No Markings = Standard Clearance

C3 = Clearance is greater than international standard

C4 = Clearance is greater than C3” (Bearing Boys, 2021).

See a full guide to bearing suffixes here.

There you have it. In the above blog post, we have described both how to measure plain plastic bearings and how to measure metal ball bearings.

Igus® makes plain plastic bearings among other engineered wear plastic products. To find out more about whether plastic bearings will work for your application, please read more here.

References:

https://www.collinsdictionary.com/dictionary/english/caliper

http://motorsportsbearings.com/how-to-measure-bearings.html

http://motorsportsbearings.com/bearing-suffixes.html

https://www.linkedin.com/pulse/how-measure-bearing-identifying-references-bearings-molly-han/