How to Make a Linear Actuator Move Faster

By Shizu Yamaguchi

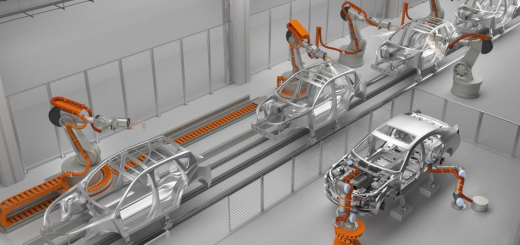

Here, we’ll cover two ways to increase the speed of your linear actuator. But first, note that the linear actuators referred to in this article are known as slide tables and linear slides (pictured below). Advice for their rod-end counterparts is not covered in this article.

With that caveat out of the way, let’s get started.

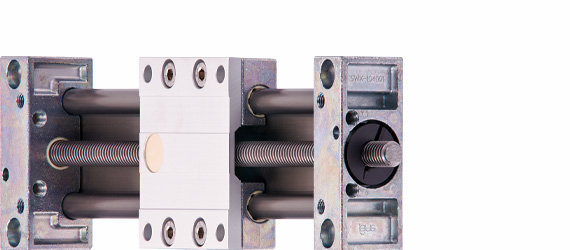

Screw-driven linear actuator

Belt-driven actuator

For screw-driven linear actuators, change the lead screw’s pitch to increase speed. For example, instead of using a standard 10×2 pitch, increase it to 10×5, 10×10 or even 10×50. That way, for every rotation of the lead screw, the carriage can travel that much farther. A single rotation of the 10×5 lead screw would increase carriage distance by 3mm, the 10×10 would increase distance by 8mm, and so on.

Screw-driven systems generally have a variety of speeds at which they can go. One way to find out maximum speeds for your application is to use an online configurator. For igus® linear slides, maximum speeds range between 0.018 m/s and 0.333 m/s.

There are limits to the speed of a screw-driven system, however, since screws start having issues when they reach the upper limits of their speeds. Lead screws might start to whip, for example.

The second way to increase the speed of a slide table is to swap out a lead screw system for a belt drive system. Belt-drive systems offered by igus can go up to about 5 m/s.

To learn more about whether a slide table from igus could meet your needs, please reach out to us by phone at (905) 760-8448 or visit our website.