3 Reasons Why Industrial Manufacturing Robots are Important

By Erin Kemal

Industrial robots are being used more and more in so many industries, no more so than the manufacturing industry. But why are these industrial manufacturing robots so important? Also, what constitutes an industrial robot?

What is an industrial manufacturing robot?

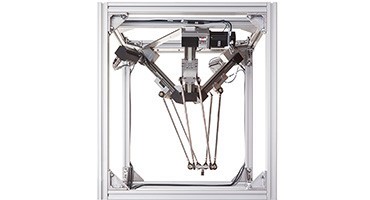

According to the International Federation of Robotics (IFR) the term “industrial robot” is standardized as: “an automatically controlled, reprogrammable multipurpose manipulator, programmable in three or more axes”. These can be further identified as:

- Cartesian

- Scara

- Articulated

- Delta

How can industrial robots help?

Within the manufacturing world there are various areas where robots are included in the manufacturing process. Areas such as:

- Warehouse

- Manufacturing

- Agricultural

- Cleanrooms

The integration of robots in these areas in the manufacturing industry, allows rapid growth where perhaps such growth wasn’t possible before.

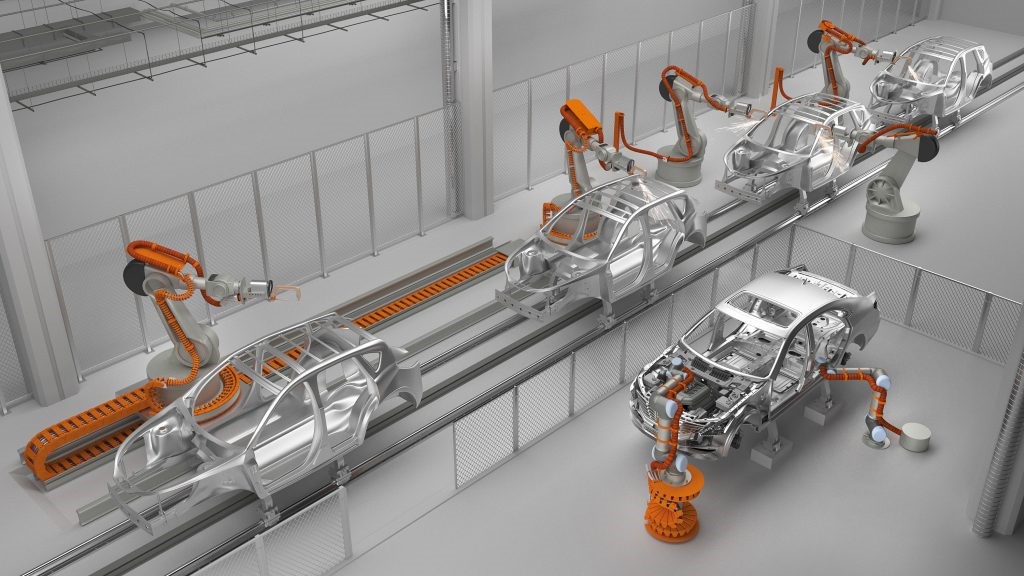

1. Warehousing with industrial manufacturing robots

Warehousing will continue to grow. In comparison, however, this will not grow as fast as other industries. This is down to a high level of industrial manufacturing robot collaboration already widespread throughout warehousing. Areas such as palletising in warehouses tend to be using industrial robots to enable larger products to be added onto pallets. With these robots, using triflex® robot dress packs not only protects the power cables to the robot, it also reduces downtime. Its modular design allows cables to be inserted quickly and easily, preventing expensive stoppages.

2. Manufacturing with industrial manufacturing robots

Robots are well established in the manufacturing industry where reliability is of paramount importance, as well as an understanding of the required maintenance and lifetime. Condition monitoring and predictive maintenance helps these industrial robots become even more intelligent. Using “smart plastics” the integrated sensors and components provide information and suggest required steps, such as maintenance or shutting down the system in order to prevent damage that is expensive to repair. Industrial robots are expensive pieces of equipment, and breakages and downtime are expenses that can be avoided with these products.

3. Cleanroom robots

The pandemic last year triggered a boom for sanitary robot solutions in hospitals, industrial facilities and test laboratories. As we start to come out of the pandemic, industries that invested in automated sanitation solutions will continue to do so, and predictions are that these will continue to rise.

Cleanroom robotics minimize contamination whereas the risk of contamination with humans is greater. Automating processes in cleanrooms with products such as the igus® e-skin® energy chain, stainless steel lead screws and stainless linear systems allow robotics to continue to work in these harsh, pristine environments.

Industrial manufacturing robots are important as they are helping collaboratively to increase growth in areas which may be struggling. If you need help with bearings, energy chains, leadscrews or cables for your robot, visit our website: www.igus.ca.