How to Use the iglide® Service Life Calculator

By Shizu Yamaguchi

Did you know that the data used to generate results from our service life calculator come from actual tests done in our 40,900-square-foot testing lab in Cologne, Germany? Or that you can order a configured bearing directly from the results page? Helpful and informative tips like these are included with instructions below in this beginner’s guide to the iglide service lifetime calculator. If you prefer, you can watch this video instead. (Instructions start at 5:20).

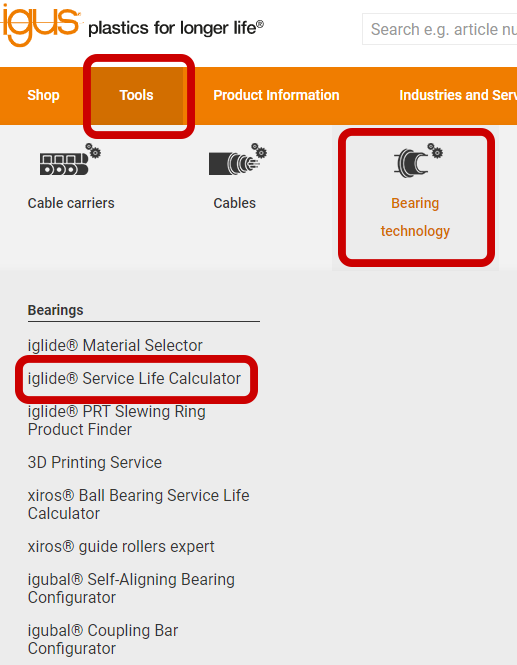

How to locate and use the service life calculator online:

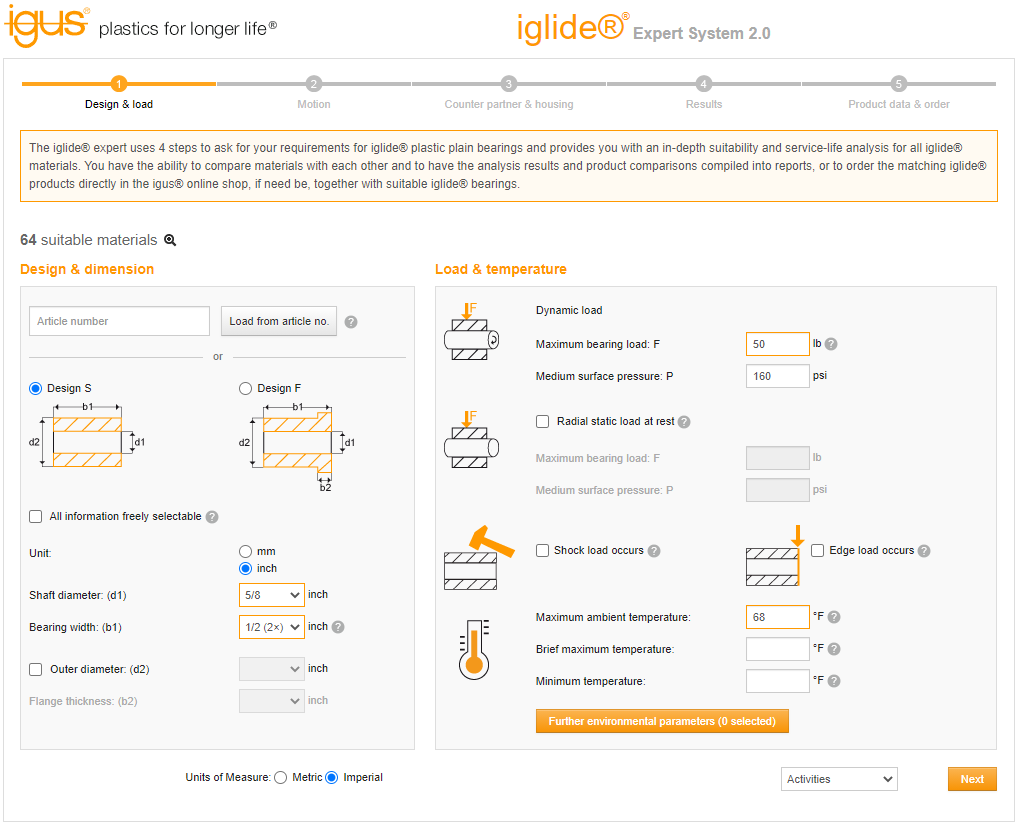

1. Design & load

Instructions:

- Enter shaft diameter.

- Enter bearing width.

- Enter the load of the bearing. (Ensure that you are entering the load of each individual bearing. For example, if you had four bearings and the total load was 200 pounds, the load per bearing would be 50 pounds).

Helpful Notes:

- Imperial or metric can be selected as units of measure (see the bottom of the tool).

- Design & dimension: If you have a part number with the dimensions you are looking for, you can enter it right under “Design & Dimension,” click on “Load from article no.” and the dimensions will automatically populate.

- Maximum ambient temperature: You have the option of entering the ambient temperature, which is the temperature the bearing is experiencing at all times.

- Brief maximum temperature: The brief maximum temperature is for a 20 minute time span.

- Further environmental parameters: Entering environmental parameters is optional. In this option, you may select chemicals that the bearing will be exposed to.

- On the upper left hand corner, you will be supplied with the number of suitable materials. As you enter in more variables, this number will likely drop, depending on what materials make sense for the entries provided.

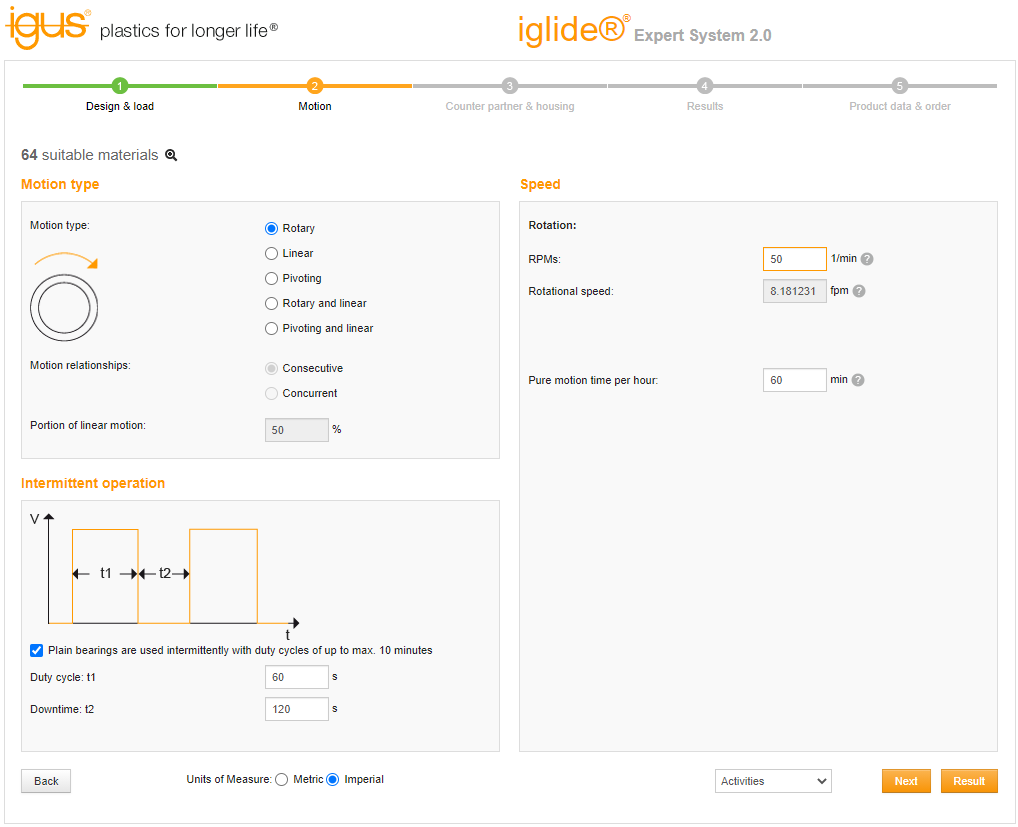

2. Motion

Instructions:

- Enter the rotations per minute.

Helpful notes:

- Motion Type: This tool is mainly for rotating, oscillating or pivoting motions, though linear can be entered.

- Pivoting: For pivoting motion, be sure that the pivot angle is half of the full pivoting angle.

- Speed: Note that for this calculator, speed and load are very important variables. Essentially for our material types, the higher the load, the lower the acceptable speed and the higher the speed, the lower the acceptable load.

- Intermittent Operation: Add the intermittent operation variables if you have them. Downtime allows the bearing to cool off, positively affecting the number of service life hours.

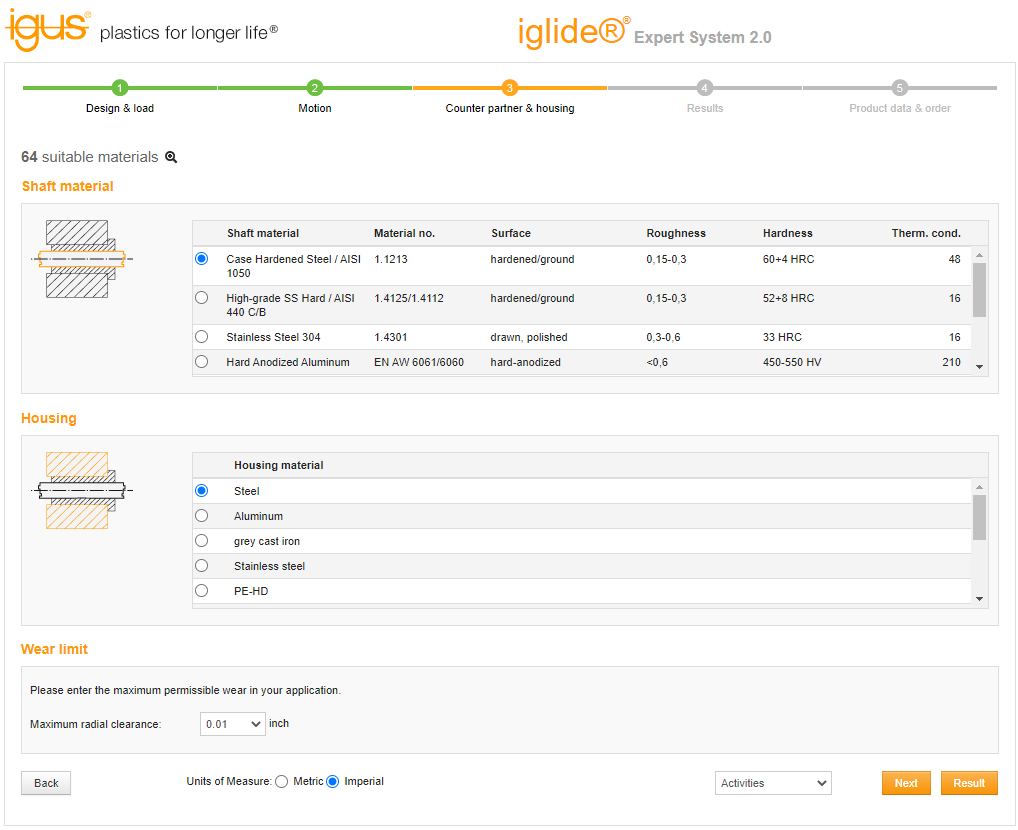

3. Counter partner & housing

Instructions:

- Select your shaft material, housing and wear limit if different from the default settings.

Helpful Notes:

- Shaft material: If your shaft material type is not on the list, try to select the material that has the most similar thermal conductivity. Otherwise, please contact sales for more information as we have data on other materials.

- Housing: Our default housing is made of steel.

- Maximum radial clearance: The service lifetime does not indicate the number of hours before catastrophic failure. Rather, the calculation indicates the number of hours leading to a certain amount of clearance or wear between the bearing and the shaft. This clearance can be set in this drop-down menu.

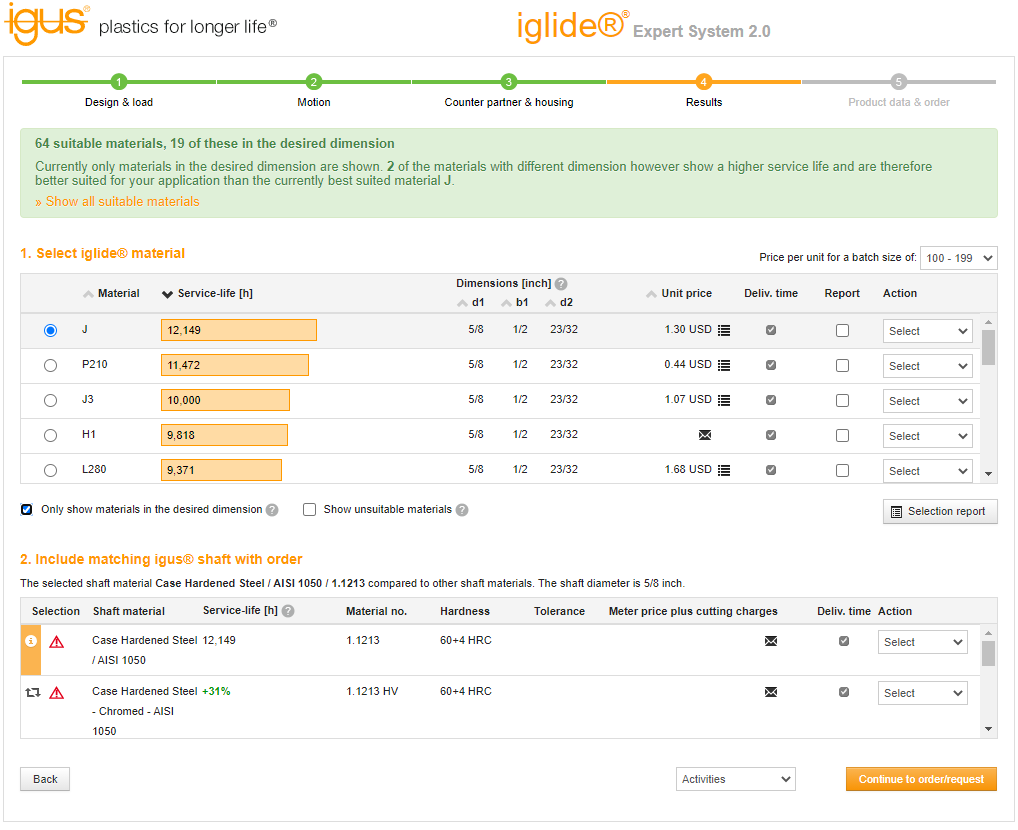

4. Results

Instructions:

- On this final screen, you will be provided with the material types and service life hours each material type would have, given the variables you have entered for your application.

Helpful Notes:

- “Only show materials in the desired dimension” can be clicked in order to see only materials that fit the dimensions entered.

- Note that the price is provided.

- The shaft type can affect the number of service life hours. If you are flexible, you can change that option on the results page to increase the number of service life hours.

You’ve made it to the Results page – now what?

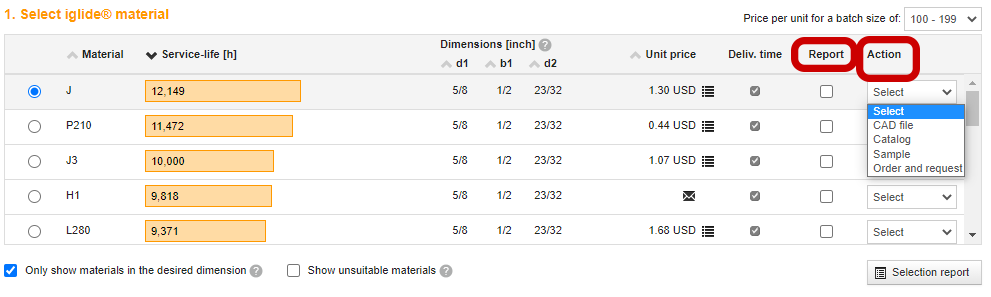

- Report: You can check multiple parts and create a selection report on all three materials. This will provide you with the data you entered as well as a comparison of service life hours. If the material is not suitable, a reason will be provided.

- Action: Your free CAD models can be uploaded. No registration is required.

- Action: You can request a sample.

- Action: You can order directly from the calculator.

Every application is unique. Trying out samples may be the next step and we are happy to provide them so you can see how our products function. Feel free to reach out to us at www.igus.ca or 1-800-965-2496.