Are lubricants really needed for format adjustments in packaging machines?

By Bastian Mehr

Most packaging machines have a number of format adjustments. They often utilize trapezoidal lead screw nuts and a corresponding lead screw. Many format adjustments are also still constructed using metal lead screw nuts like bronze or steel. To work smoothly, these designs need lots of lubrication. The dirty environments seen in packaging applications mean that regular re-greasing and maintenance are necessary.

A non-functional format adjustment that brings the entire production line to a standstill is a nightmare that many people either know–or fear–because as we all know, downtime is money. You want to focus on more important areas of production, and not maintaining and greasing metal lead screw nuts. Perhaps you would like to dispense with format adjustment lubrication entirely and enhance your system’s operational reliability altogether?

Self-lubricating format adjustments

Then there is just one alternative: self-lubricating format adjustments in packaging machines. To eliminate lubrication, igus® uses lead screw nuts made of high-performance polymer. The polymer nuts have many advantages over conventional ball screws. They are designed specifically for dry operation, and solid lubricants have been compounded into the materials. These high-performance polymers are self-lubricating so there is no need to grease the lead screw nuts. This keeps dirt, such as paper fiber from cartons or corrugated materials, from adhering to them, entering the system and accelerating wear.

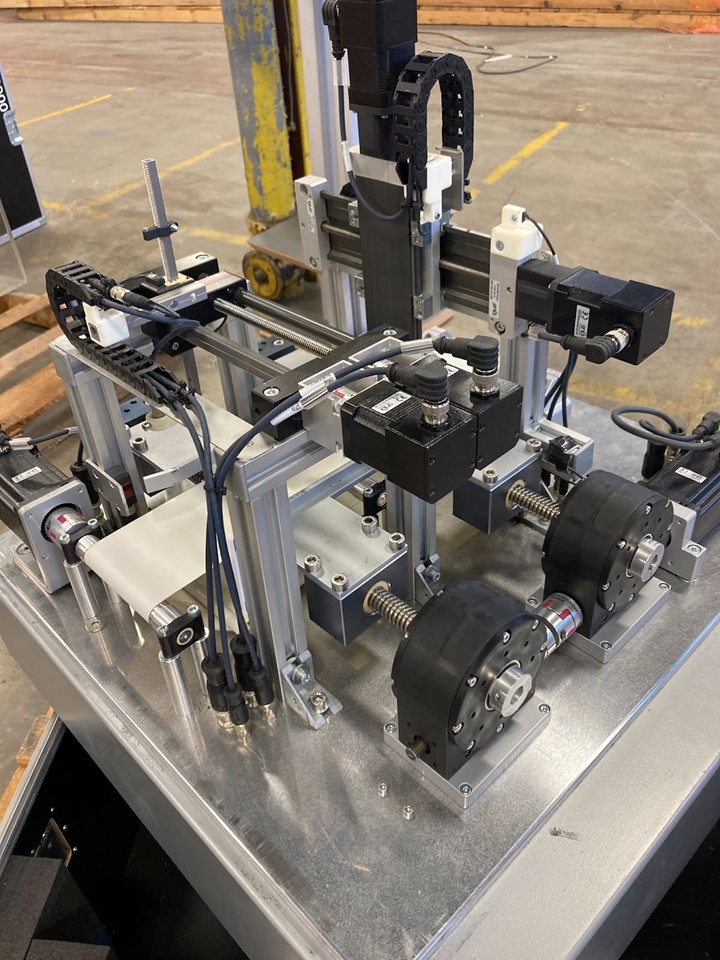

The image below shows a machine in which igus® lead screws are used to control the horizontal format adjustment for the lane width. The design shows how igus® lead screws can be used independently or in combination with a linear guide system such as our drylin® products. While the image below shows a fully automated version controlled by and synchronized with servo motors, igus® lead screw nuts can also simply be integrated into hand-moved applications where a handwheel is used.

If metallic nuts cannot be maintained or re-lubricated, the lead screw will wear until the application seizes. dryspin® polymer lead screw nuts are maintenance-free throughout their entire service life. This is a critical advantage for hard to reach areas that can often be overlooked when it comes time for maintenance schedules. Corrosion resistance and, for some materials, chemical resistance, are necessary for nuts to function smoothly even in areas that are frequently and aggressively cleaned.

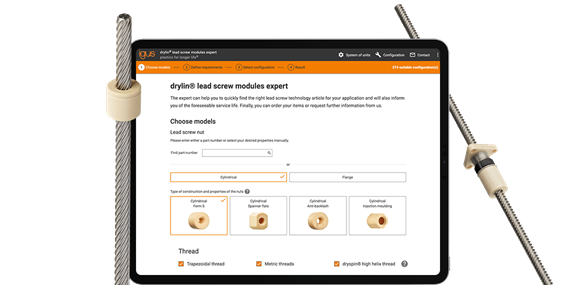

Lead screw nuts are available in a number of materials for a wide range of application areas. Dry or wet, high or low temperatures, food-grade or hygiene-sensitive areas–igus® materials can handle just about anything. Lead screw technology is also available in a wide range of geometries, ensuring simple 1:1 replacement.

Discover self-lubricating lead screw technology in our online shop.

Format adjustment service life

As described above, lead screw drive service life is a critical factor for maintenance-free format adjustments in packaging machines. As with all products, igus® performs countless tests on them to determine service life in a wide range of applications. Numerous tests were also performed for various lead screw and lead screw nut materials and geometries. To precisely calculate the probable service life for your application, you can use our free online tool.

Calculate the service life here.

Summary

It is clear that lubricants can be dispensed within format adjustments. drylin® lead screw technology with its dry running, lubrication and maintenance-free lead screw nuts offers a reliable alternative to conventional lead screws. The long service life, various materials and geometries, and quick availability are also decisive advantages of polymer lead screw nuts.