Reducing car weight through seating adjustments

By Jared Worth

Finding ways to reduce weight in automotive manufacturing is an ever-lasting battle. Reducing weight has all sorts of benefits for performance, such as faster acceleration, reduced braking time, better handling, increased fuel economy in gas-powered vehicles, or battery life in an EV. One of the easiest ways to do so is through components used for seating adjustments: linear bearings and plain bearings, flexible cables, cable carriers, etc. Read on for a closer look at how exactly igus® can provide lightweight alternatives to traditional components in the automotive industry.

Why is vehicle weight so important?

In the world of automotive manufacturing, weight is one of the single most important considerations for engineers. Weight has a direct effect on the fuel economy/battery life of a vehicle, with more weight reducing the fuel economy/battery life and less weight improving it. According to a study published by MIT, a 10% reduction in weight can cut fuel consumption by as much as 7%1. The same study also suggests the possibility of a 40% weight reduction in vehicles solely through downsizing the vehicle, using lighter materials, and redesigning the vehicle, leaving much room for improvement in this regard.

Shipping costs and emissions also need to be accounted for when it comes to the weight of automotive components, as transport of the products will cost more and eat up more fuel at heavier weights. Considering standard North American semi-trucks can legally have a gross vehicle weight rating (GVWR) of as much as 80,000lbs including cargo, this is a major factor to consider. Lighter components could either mean reducing the total weight of a shipment and greatly reducing shipping costs, or fitting more components in a single shipment of the same weight. Either way, the potential benefits are significant.

Plastic vs. Metal

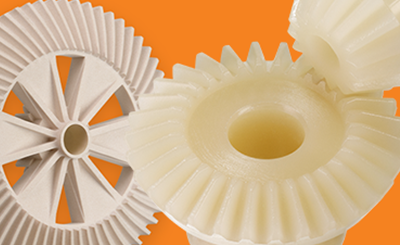

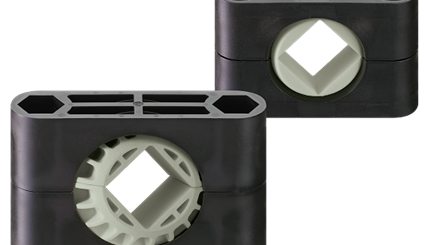

At the most basic level, choosing a bearing material for automotive production comes down to a decision between plastic and metal. As far as weight is concerned, plastic is by far the superior choice. A single modern car seat can use as many as 30 plain bearings! While the weight of a single bearing may seem near-negligible, having up to 120 of them used in seating alone causes the weight to add up quickly. That’s not to mention all the bearings used throughout the rest of the vehicle as well. When you consider that plastic plain bearings – made from iglide® materials, for example – can weigh as much as five times less than traditional metal bearings, the difference in weight becomes staggering. Outside of weight, iglide bearings offer other distinct advantages, such as self-lubrication, quiet operation, and longer service life.

Bearings aren’t the only type of component that igus offers for automotive seating adjustments. Linear slides and bearings, e-chain® cable carriers, and chainflex® cables are all suited for use in automotive seating – especially as automotive production becomes more advanced – and in nearly all cases are a much lighter alternative to other products on the market. Add in reliable service life predictions, the lack of required maintenance, and easy installation, and you have the perfect recipe for success.

Questions about how you can implement igus products into your automotive application? Contact an expert here, or call us at (800) 965-2496. You can also check out our Automotive Solutions playlist on Youtube here!