What is PROFIBUS and how does it work

By Jared Worth

Factory automation is going to inevitably become more difficult to implement as factories grow in size and become more advanced. Running cables from a control room to each field device in the factory creates unnecessary work and drives up costs. However, PROFIBUS networks solve this issue by bringing I/O connections to the factory floor, eliminating the need for convoluted cable solutions spanning the entire factory. Read on to learn more about PROFIBUS and why it remains a leading option for factory automation.

What is PROFIBUS?

PROFIBUS (Process Field Bus) was originally created in 1989 as a way to establish communication between field sensors and system controllers in factories. A number of different variants exist, the first of which is called PROFIBUS FMS (Fieldbus Message Specification). This variant was replaced in 1993 with PROFIBUS DP (Decentralized Periphery), which is still one of the most widely used variants today.

Other variants include PROFIBUS PA (Process Automation) and PROFINET. Technically, PROFINET is an entirely separate protocol that operates via ethernet, but shares many of the same key functions of PROFIBUS. PROFINET is expected to gradually replace PROFIBUS systems in the coming years due to higher transmission speeds and the future-proof nature of PROFINET’s ethernet architecture.

PROFIBUS DP

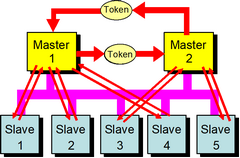

PROFIBUS DP is a type of fieldbus protocol that allows communication between a “master” controller device and a number of “slave” field sensors. It operates on the physical layer RS-485 —the same physical layer as Modbus — but it has a specialized token ring protocol that enables multiple master devices to exist on the same network, differentiating it from other bus networks. A “token” is passed between masters, and whichever master is holding the token has the exclusive ability to communicate with slave devices on the network.

There are two classes of master devices for PROFIBUS networks, class 1 and class 2. A class 1 master is the “main” master device, responsible for cyclically requesting data from every slave. A class 2 master acyclically communicates with slave devices for the purposes of diagnostics and setting device parameters. Due to the acyclic nature of class 2 masters, they don’t need to be permanently connected to the network.

The term “decentralized periphery” is derived from the structure of a PROFIBUS DP system. Instead of having every single field device in a factory connected to the programmable logic controller (PLC) directly via extensive cabling, PROFIBUS DP decentralizes the I/O connections and brings them to the factory floor. This shortens the length of cable needed to connect field devices to the I/Os, and only a single cable is needed to connect the I/Os and PLC. Ultimately this reduces both cost and complexity of the entire system.

PROFIBUS PA

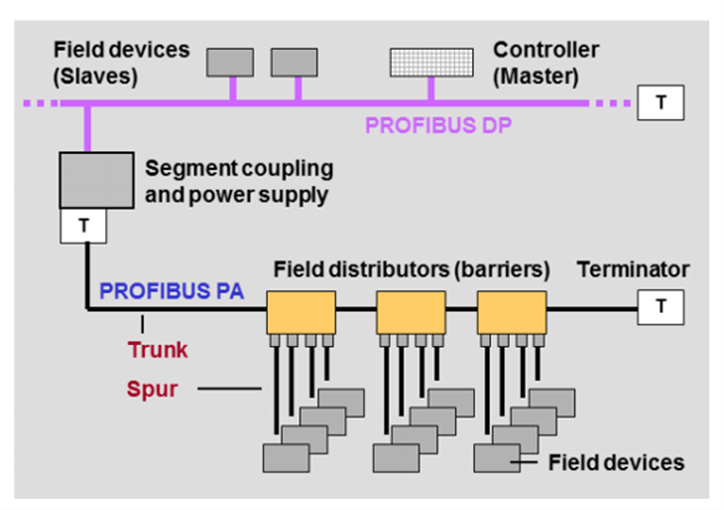

PROFIBUS PA is designed specifically as a solution for process automation. The slower data transmission rates offered by PROFIBUS PA are suitable in process automation where procedures are typically slower than factory automation. Unlike PROFIBUS DP, PROFIBUS PA’s physical layer is Manchester-encoded Bus Powered (MBP).

MBP is an intrinsically safe physical layer, allowing PROFIBUS PA to be used in hazardous environments where explosion protection is a necessity. This difference in physical layers affects the possible topologies of each system. PROFIBUS DP is typically limited to a daisy-chained linear structure of up to 32 nodes (more nodes are possible if a repeater is used). Alternatively, PROFIBUS PA is capable of practically any topology, though trunk & spur is the most common.

PROFIBUS DP and PA systems can be combined through the use of a segment coupler. Since PLC’s don’t have a PROFIBUS PA port, a coupler is necessary to convert the PA signal to a DP signal that the PLC can read. Combining these two systems is common, and is especially useful when a subset of field devices is operating in a hazardous area in a system otherwise able to be serviced with PROFIBUS DP.

PROFINET

Fundamentally, PROFINET serves the same purpose as PROFIBUS networks. I/O connections are able to be decentralized and brought to the factory floor, cutting costs and complexity. The key difference between the two is in the type of cable used — PROFINET cables are a subset of ethernet cables designed for heavy-duty factory applications. This eliminates the need for specialized switches like those used in RS-485 architecture and enables the use of various topologies like tree, star and ring.

PROFINET’s use of ethernet makes it capable of integration with IIoT networks, which can eliminate unplanned downtime and improve the efficiency of the entire facility. The use of ethernet cables also allows for significantly higher transfer speeds of 1Gbps or more. As the capabilities of ethernet improve so will the capabilities of PROFINET. In this way, PROFINET is essentially future-proof.

EtherCAT

In large networks with an entire factory being automated as mentioned above, there’s another alternative that can be put to use: EtherCAT. EtherCAT is an international fieldbus-based ethernet system first developed by Beckhoff and later donated to the EtherCAT Technology Group. The main advantage of EtherCAT is its high level of optimization that provides significantly faster speeds than other systems like PROFINET or PROFIBUS. It also uses timestamping to determine latency of various nodes in the network, improving accuracy significantly. All of this comes together to create a system that is ideal for handling the sheer amount of data that needs to be processed in full factory automation.

Conclusion

PROFIBUS is essential in factory automation and isn’t going anywhere any time soon. Even with PROFINET offering a faster, simpler solution, it’ll be years before it takes over as the clear-cut top option over PROFIBUS.

For questions about implementing PROFIBUS in your own factory and choosing the ideal cables based on your application, contact our chainflex® cables expert. To browse our extensive offering of continuous-flex cable — including BUS, motor, robot, and control cables — visit our online shop.