Smart factory: intelligent plant monitoring with the FANUC FIELD system

By Richard Habering

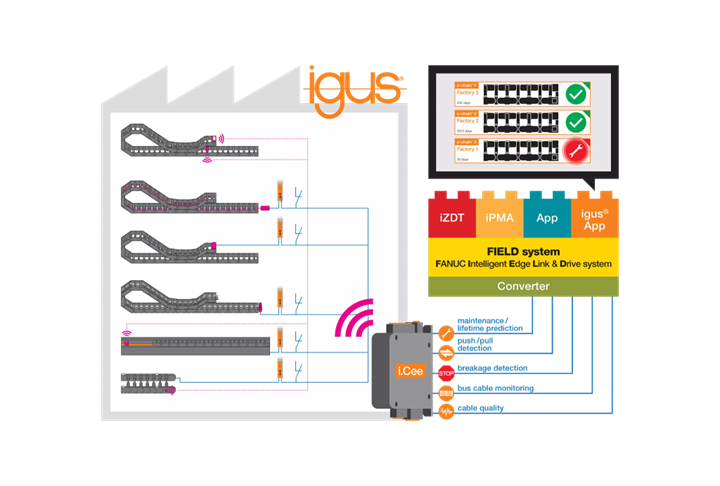

To evaluate data from machines and systems, FANUC, an international robot manufacturer, offers its “FIELD system” open industrial IoT platform. The system uses local network topology to connect production machines from all manufacturers, allowing comprehensive data analysis for the entire process chain. This is a core element of a smart factory. The infrastructure uses apps from FANUC and third-party suppliers. igus® has recently developed a special app for this–the i.Cee smart plastics app. Maintenance personnel can use this app to monitor the condition of their igus® smart plastics components, such as e-chain® cable carriers and chainflex® cables, and plan maintenance work predictively.

Networking is often a key word where predictive maintenance and Industry 4.0 are concerned. Industrial IoT platforms are also used. FANUC, an automation specialist, has developed such a platform in recent years. The FANUC Intelligent Edge Link & Drive system (FIELD for short) allows networking production machines. It can work on premises or, in the future, with a Cloud link. The system collects and analyzes machine data on site. The machines’ operating and sensor data can therefore be collected centrally with just one server and viewed whenever required. Efficiency is easy to monitor, production processes can be accelerated, and maintenance work can be planned. Due to the openness of the platform, all machines can be connected to the system. Apps for the system are provided by FANUC and by third-party suppliers.

Thanks to intensive cooperation, the smart factory can finally become reality

igus®, the motion plastics specialist, has also developed an app for its smart plastics solutions for condition monitoring and predictive maintenance and made it available to the FIELD platform. Once the igus® i.Cee app has been integrated, users can monitor the condition of their e-chains and cables at any time and plan maintenance work predictively. The central element of the predictive maintenance system is the i.Cee software. It works with sensors on the e-chain, plain bearings and bushings, or a linear carriage to transform products deliverable from stock into smart products. This upgrade enables you to determine your igus® products’ maximum service life and the perfect time for servicing. The i.Cee software and a few sensors transform standard products into smart energy supply systems or bearing technology in no time at all:

- Avoid expensive production stoppages

- Predict maintenance precisely

- Maximize the service life of the components you are using

- A simple step towards integrating your system(s) into the networked smart factory

Under the i.Sense name, igus® offers a wide variety of sensors that detect the condition of igus® components. Among other things, they measure wear during operation and alert the user as soon as repair or replacement is necessary. The i.Cee communication module provides the igus® data via an integrated OPC-UA server. This data is then fed into the platform with the FANUC Converter. Because the FIELD system is open, the user can consult the data and service life predictions for all igus® products in a protected local network environment. The igus® i.Cee app tells the maintenance engineer the number of days until he needs to perform crucial maintenance. FANUC and igus® therefore automatically prevent unplanned plant downtimes by creating a smart factory.

Download smart_Fanuc_FIELD_system_EMO_Igus_EN

If you have any questions regarding smart plastics in use with our bearings or linear bearings, please contact our smart plastics drylin® expert here. For questions regarding smart plastics in use with our cable carriers and cables, please contact our smart plastics e-chain® expert here. You can also contact us by phone at (800) 965-2496.