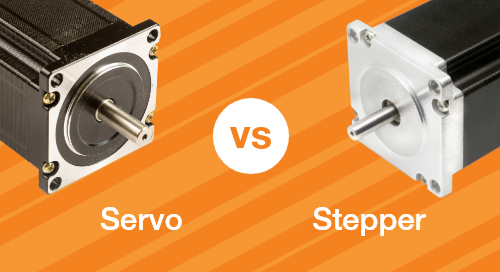

Servo Motor vs. Stepper Motor: Choosing the Right Motor for Your Application

By Jared Worth

When it comes to precision motion control in engineering applications, two popular choices emerge: servo motors and stepper motors. Both serve specific purposes and offer unique advantages, but selecting the appropriate motor for your project is crucial to ensure optimal performance and efficiency. In this blog, we will delve into the differences between servo motors and stepper motors, their respective advantages and limitations, and provide insights to help you make an informed decision for your engineering endeavors.

Understanding Servo Motors

Servo motors are closed-loop control systems designed for high-precision motion control. They consist of a motor coupled with a feedback sensor (typically an encoder) that continuously relays position, velocity, and acceleration information to a controller, enabling precise movement and real-time adjustments.

Advantages

- High Accuracy: Servo motors offer exceptional accuracy and repeatability, making them suitable for tasks that require precise positioning, such as robotics, CNC machines, and automated manufacturing.

- Speed and Torque Control: The closed-loop system allows servo motors to maintain a constant speed and deliver varying levels of torque, even under changing load conditions.

- Reduced Heat Generation: Servo motors are more efficient compared to stepper motors, resulting in lower heat dissipation during operation.

Limitations

- Cost: Servo motors are generally more expensive than stepper motors, mainly due to the added cost of feedback devices and complex control systems.

- Complex Control: Configuring and tuning the control parameters for servo motors can be challenging and requires specialized knowledge.

Exploring Stepper Motors

Stepper motors (sometimes referred to as a spindle motor) are open-loop systems that move in discrete steps, with each step corresponding to a fixed angular displacement. They do not require feedback devices like encoders because the controller sends precise pulses to the motor, dictating its position.

Advantages

- Cost-Effectiveness: Stepper motors are more affordable than servo motors, making them a popular choice for budget-conscious projects.

- Simple Control: The open-loop nature of stepper motors simplifies their control, and they are relatively easy to implement without requiring complex control algorithms.

- Holding Torque: Stepper motors can hold a position without the need for continuous power, which is beneficial in static holding applications.

Limitations

- Limited High-Speed Performance: Stepper motors suffer from a phenomenon called “resonance” at higher speeds, reducing their effectiveness in high-speed applications.

- Less Accurate: Stepper motors may experience positioning errors due to missed steps, especially in dynamic load conditions.

Choosing the Right Motor for Your Application

Finally, it comes time to choose the type of motor that best suits your application. However, there are a few key considerations that need to be made and questions answered before doing so.

Considerations

- Precision Requirements: If your application demands high precision and accuracy, especially in dynamic environments, a servo motor may be the better choice.

- Budget Constraints: For cost-sensitive projects with moderate accuracy needs, a stepper motor could be a suitable option.

- Control Complexity: Evaluate your team’s expertise and the complexity of the control system required. If you lack experience in advanced control algorithms, a stepper motor might be more manageable.

Conclusion

In summary, the decision between using a servo motor or a stepper motor heavily depends on the specific requirements of your engineering application. Servo motors offer unparalleled precision, speed, and torque control but come at a higher cost and require more sophisticated control systems. On the other hand, stepper motors are budget-friendly and straightforward to control, but may not deliver the same level of accuracy and high-speed performance. By carefully evaluating your project needs and considering the advantages and limitations of each motor type, you can make a well-informed choice to achieve optimal results in your engineering endeavors.

For questions about choosing a motor for your application, contact an expert. For more information about the motor controllers igus® offers and when to use each, check out our Tech Talk!