3 easy ways to solve the obsolete part issue

Doesn’t it just grind your gears when a crucial part of your apparatus fails, only to discover that the original manufacturer has ceased its production? The financial implications can be significant, especially if the unavailability of this single component threatens to render the entire machine obsolete.

But what do the terms “obsolete and obsolescence” truly mean?

Obsolete or obsolescence

“Obsolescence is the state of being which occurs when an object, service or practice is no longer maintained, required or degraded, even though it may still be in good working order”.

“Obsolete also refers to something that is already disused or discarded or antiquated. Typically, obsolescence is preceded by a gradual decline in popularity”. – Both quotes (taken from Wikipedia) give us clear insight as to the definitions of and differences between the two terms.

Obsolete parts come with their own set of pros and cons. On the downside, as previously discussed, the cost can escalate if a suitable replacement is hard to come by. On the upside, it opens up an opportunity for innovation, giving you the liberty to design a superior component. Fortunately, with the strides we’ve made in technology, obsolescence should soon be a relic of the past.

Here are 3 ways igus® provides to solve the obsolete part issue:

- 3D print

- Machine from stock materials

- Complete redesign of part

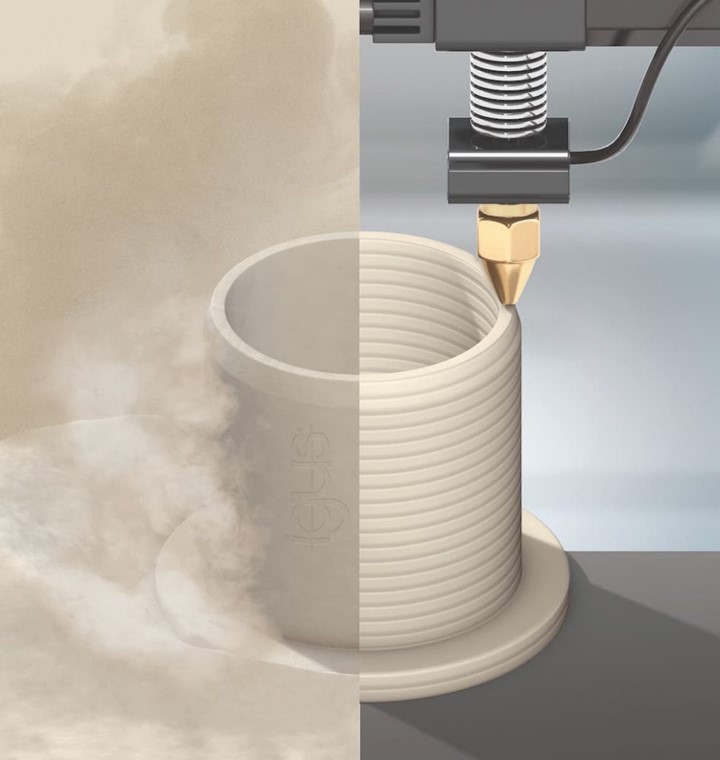

3D print

3D printing is ideal for obsolete parts. It is cost-effective with no set up costs, allowing flexibility if you want to adjust the component design, and it is quick to produce.

igus offers FDM filament or SLS (selective laser sintering) printing, with the additional benefit of using an igus® material that is not only wear-resistant, but has high performance tribological properties that all igus® materials have.

With our 3D drawing system, you can drop a CAD file into the configurator, select the best material based on the parameters shown and order it. It really is that simple.

Machine from stock materials

We’re equipped to support machining from stock materials. Our team can help you take a tangible component, model it, and provide a quote. With a broad selection of igus® materials at your disposal, you’re granted design flexibility while still maintaining technical material properties. This approach to manufacturing obsolete parts, which has no minimum order quantity, is ideal for those in need of custom designs. We possess the capability to machine parts using methods such as CNC milling, turning, routing, and even laser cutting, selecting whichever technique is most efficient and cost-effective.

An example of this process:

A short while ago, we welcomed a new client who needed a solution to a problem. He owned a milling machine that had become obsolete due to its age, and the steel bearings it required were no longer available. The client provided us with the measurements and the worn-out part. After extensive discussions, we agreed to manufacture the parts using iglide® J material. We had previously worked on a similar application, so we had a clear direction.

Our discussions were supplemented with the igus® online expert systems, which provided wear data on the parts to predict their lifespan. If the application information – such as loads, speeds, shaft material, shaft size, housing materials, and dimensions – is available, then our website’s online calculators are an invaluable tool for planning your parts.

The part was subsequently designed using iglide® J material, and samples were dispatched for in-application testing.

The testing phase was successful, and the issue was resolved using igus® technical polymers.

Complete redesign of part

At times, an obsolete part may be so deteriorated that it’s unrecognizable! This can complicate the process of recreating and manufacturing the part, but with the expertise of igus® engineers in all things plastic, we can guide you through the process of remaking the part. Additionally, we offer samples for testing and can adjust the design as needed.

We’re in the process of developing a new feature for our website that will allow customers to upload their part details. This tool will not only select the best material for the application but also provide pricing and lead time information. This will be an invaluable resource for customers, complementing any assistance required from the igus® experts. So, stay tuned!

While obsolete parts can be a nuisance, they no longer signify the end of a machine’s lifespan. Reach out to us, we’re here to help.