Improving pipetting reliability & efficiency with automation

By Jared Worth

Pipetting is a highly technical skill, requiring precision and repetition over potentially long periods of time. Without the proper training & execution — along with steady hands and a healthy dose of patience — pipetting results can vary wildly. Thankfully, many of the challenges with manual pipetting can be solved with automation. Read on to learn how automation is making pipetting easier, faster, and more reliable.

What is pipetting?

Pipetting is the process of using a pipette — a tube-shaped tool used to measure and dispense small amounts of liquid — to move liquid from one container to another, usually for the purpose of an experiment or dosing out medications.

Typically pipetting is used for small volumes of liquid, from milliliters down to microliters. Pipettes that measure in microliters are referred to as micropipettes.

Types of pipetting

Pipetting can be broken down into three main categories when talking about automation: manual, semi-automated, and automated. These different categories are explained below.

Manual pipetting

Manual pipetting is handled entirely by humans, and is the “traditional” form of pipetting. This requires the most technical skill, and leaves the most room for error. It also brings with it the risk of repetitive strain injuries(RSIs), and potential contact with hazardous samples. Finally, manual pipetting is the slowest of the various methods, taking up over 80% of the workday in some cases.

Semi-automated pipetting

Semi-automated pipetting blends automated and manual pipetting to make the process easier for technicians. Certain steps, like setting pipetting volumes, tip ejection, or the actual dispensing of liquid, can be automated, while still requiring a technician throughout the process.

This is faster than manual pipetting and lowers the risk of RSIs, but doesn’t achieve the same throughput of fully automated solutions and still presents the risk of technicians coming into contact with potentially hazardous samples.

Automated pipetting

Automated pipetting can eliminate the need for human intervention, whether for just a few specific steps, or an entire process beginning to end. Automated pipetting is best suited to high volume applications since up-front costs are much higher than with manual or semi-automated pipetting; however, labor costs are much lower.

Why automate your pipetting processes?

Automating the pipetting process may sound expensive and time-consuming at first. After all, automation is still relatively new and requires expertise to properly implement. However, the benefits largely outweigh the initial cost & time investment (which can be significantly reduced through the RBTX marketplace).

More accurate dispensing

Accurate dispensing can be extremely difficult to achieve when manually pipetting — especially over a long period of time — even with frequent breaks. However, automated pipetting can achieve highly accurate dispensing as long as the system has been properly calibrated. Things like pipette angle and immersion depth will be the same every single time.

Lowered risk of RSIs

Repetitive strain injuries can be fairly common in pipetting applications due to the nature of the movement required. Since automated pipetting systems don’t require human intervention, or at the very least significantly reduce this need, the risk of RSIs is all but eliminated.

Increased throughput

Automation increases the throughput of pipetting applications in two different ways. First, the process itself can be performed quicker and with a higher level of accuracy versus a human performing the same process. Alternatively, automated systems can be developed that operate up to dozens of pipettes at once, drastically increasing throughput compared to a human pipetting with a single device. If an application doesn’t call for such high throughput, simpler systems can be developed for single channel applications at a more reasonable cost.

RBTX Marketplace

If you’re not sure where to start with your automation project, or simply worried about the cost of implementation, the RBTX marketplace is the perfect place to start.

The two primary goals of RBTX are to lower the cost of automation and make implementation as easy as possible. To this end, experts are available to help choose the lowest-cost components that meet your application requirements, as well as offer advice on installation and integration.

A basic automatic pipetting solution from RBTX can cost less than $3,000 and offer a 3-month return on investment.

Plastic components for automated pipetting

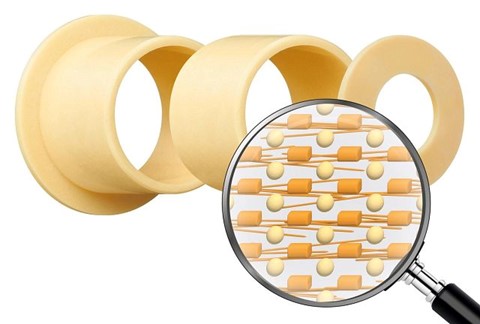

Once you’ve made the decision to automate your pipetting processes, the next steps are choosing components & hardware and integrating them. Metal ball bearings are often chosen as part of the guide system for lift and travel movements, however these bearings require constant external lubrication.

External lubricants can prove especially challenging in medical applications like pipetting where contamination of samples is a primary concern. Even worse is the potential of total system failure due to inadequate or improper lubrication.

Plastic plain bearings completely eliminate the need for external lubrication due to embedded solid lubricants. These solid lubricants ensure even lubrication across the entire bearing, increasing service life and avoiding the risk of contamination.

Plastic plain bearings also are more cost-effective and lighter than their metal counterparts, making them an even more attractive choice for automated pipetting applications.

Conclusion

Given the technical skill required for proper pipetting and low margins of error, automating the process offers significant potential for cost and time savings. Whether it’s a single channel application with limited throughput, or a massive multi-channel application, automation can increase pipetting efficiency and quality.

For help with your own pipetting application, contact an expert! To learn more about automated pipetting, check out our white paper.