Predictive Maintenance vs Preventive Maintenance

By Jared Worth

Any maintenance schedule serves the purpose of keeping machinery running as long as possible and without defects. However, there are different types of maintenance schedules that take various approaches to the process. Two of the most common are predictive maintenance and preventive maintenance.

Both predictive and preventive maintenance are scheduled in advance, but scheduling differs between the two. Predictive maintenance is scheduled based on machine condition, and preventive maintenance is scheduled based upon a specific time interval.

What is predictive maintenance?

Predictive maintenance falls under the umbrella of the Industrial Internet of Things (IIoT), and is a form of condition-based maintenance that isn’t performed until machinery falls out of predefined performance parameters. Condition monitoring is used to measure and keep track of machine performance and alert operators of abnormal performance.

Once performance parameters fall out of an acceptable range, maintenance is scheduled in advance based on predictions of remaining service life. This helps maximize machine uptime and reduce labor costs, as maintenance is only performed when it’s truly needed.

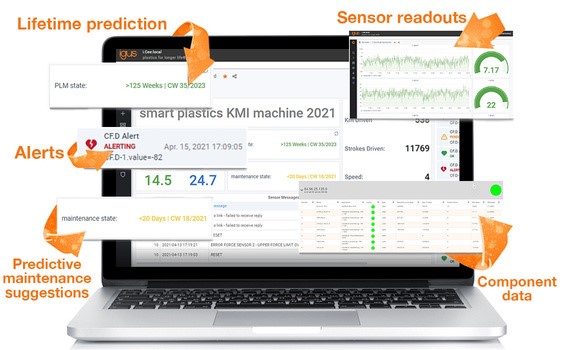

For predictive maintenance to be effective, digitalization is essential. A litany of data is collected with condition monitoring, and without an effective way to visualize that data, it’s near-useless.

The i.Cee Dashboard from igus® helps visualize the data gathered with condition monitoring sensors

Due to the need for digitalization and the related employee training, predictive maintenance has a higher initial cost than other maintenance strategies. This can be a deterrent for smaller organizations or those dealing with a limited budget, but in the long-term predictive maintenance can provide significant cost savings.

What is preventive maintenance?

Preventive maintenance is a regularly scheduled form of maintenance, similar to a routine oil change for a car or a yearly doctor’s exam. Schedules for preventive maintenance are strictly time-based, though the time interval chosen is based on expected service life to minimize the risk of parts failing prematurely.

Labor costs for preventive maintenance are more expensive than other forms of maintenance, since maintenance is performed whether or not it’s strictly necessary to keep a machine running. However, initial costs are lower as there’s no need for extensive training or investment into digital systems.

Predictive maintenance vs preventive maintenance: Key differences

There are a few primary differences between predictive and preventive maintenance that will determine which best fits a particular situation. The biggest difference, of course, is how maintenance is scheduled. Like previously mentioned, predictive maintenance is based on machine condition, whereas preventive is regularly scheduled.

Since preventive maintenance is performed regularly, the associated costs can easily be predicted in advance. However, these costs are higher since maintenance is performed more often. Preventive maintenance is also inherently less risky than predictive since maintenance is performed before a machine is falling out of acceptable performance parameters.

Predictive maintenance costs cannot be easily predicted, since they depend on machine performance and intervals can vary. However, this means maintenance is only performed as it’s needed, reducing total maintenance costs versus preventive maintenance.

There is a higher risk associated with predictive maintenance, since machines are run much closer to the point of failure. However, the risk pays off with successful predictive maintenance and leads to increased working hours and minimized costs and resources spent on maintenance.

Recap

While similar, the differences between predictive and preventive maintenance are essential to understand to ensure the ideal choice between the two is made. Below is a recap of these differences.

Predictive Maintenance

- No set schedule

- Higher initial cost, lower long-term cost

- High risk

- Maximizes time between performing maintenance

Preventive Maintenance

- Regularly scheduled

- Lower initial cost, higher long-term cost

- Low risk

- Maintenance is performed whether or not it’s essential for further operation

To learn more about igus’ Industry 4.0 solutions, visit our webpage or browse our blogs, videos and white papers. For questions about predictive or preventive maintenance — or other related Industry 4.0 topics & applications — contact an igus expert.