What are the different types of industrial robots?

By Avory Brookins

Automating laborious tasks can help save time, increase production and improve the quality of your products. But before giving automation a go, it’s important to know the difference between the industrial robots on the market. This blog post provides a brief overview of five of them: Cartesian, gantry, delta, articulated and SCARA. You’ll learn how they work, their suitable applications, and how to choose the robot that’s right for you.

1. Cartesian and Gantry Robots

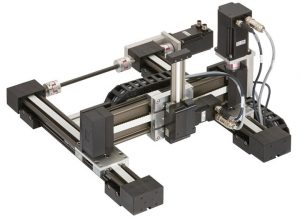

People often think Cartesian and gantry robots are the same or that their names are interchangeable – but that’s not the case. It’s true that they’re both linear robots, but each one falls into its own category because of their axis configurations.

Typically, Cartesians have a base X axis, a cantilevered Y axis, and/or a Z axis that move up and down, in and out, and side to side. Gantries, however, are configured with two base X axes, a supported Y axis that spans across the two X axes, and an optional cantilevered Z axis (as shown above and below). Each robot requires a mounting frame, unlike other robot types such as deltas and robotic arms (discussed below).

Because they’re highly configurable, Cartesian and gantry robots are commonly used for numerous industrial applications, including pick and place, sorting, labeling, measurement, inspection automation and repetitive material handling. You can adjust their precision, speed, stroke length and size, and add almost any type of linear actuator with any variety of drive mechanisms. Gantries can handle larger payloads and much longer stroke lengths since the Y axis is supported.

2. Delta Robot

Delta robots, also called parallel or spider robots, consist of three arms and a single base. The base is mounted above the work area while the arms move at high speeds (i.e., 200 picks per minute) with the help of motors on each axis (Process Solutions Inc). However, the delta’s payload capacity is lower than that of other robot types.

Deltas are ideal for light-duty pick-and-place tasks in the food, electronics and pharmaceutical industries.

3. Articulated Arms

Articulated robots, or robotic arms, are fixed to a base with a rotating joint. The arms can be designed with up to 10 rotary joints that act as axes but typically only feature 4-6. Each additional axis enables more motion.

Articulated robots are perfect for complex movements, such as reaching under something to grab a part, because they move like human arms. They can also pitch, roll and yaw, which allows for more directional control than SCARA robots (discussed below). Robotic arms are used for arc welding, material handling, assembly, packaging, machine tending and palletizing.

They have a predesigned reach and accuracy ratings that make it easier to establish their repeatability of movement (Richard Vaughn). However, unlike Cartesian and gantry robots, you’re locked into those design features once you buy it. Robotic arms could also cost more because of expensive features like proprietary controllers.

4. SCARA

SCARA stands for selective compliance assembly robot arm or selective compliance articulated robot arm. It has three axes (X, Y and Z) for rotating and lateral movements and is ideal for vertical assembly, bio-med and palletizing. However, SCARA’s arm is essentially a lever that limits its reach.

SCARA robots share similar features with robotic arms: they come predesigned for specific performance ratings, can execute complex tasks, may cost more because of expensive features, take up less space, and weigh less than other types of robots.

Which is the best robot to choose?

According to Vaughn, it’s important to evaluate the needs of your application by profiling the job’s load, orientation, speed, travel, precision, environment and duty cycle.

Load: A robot’s maximum load capacity (typically included in the robot’s part number) must be greater than the total weight of the payload at the end of the robot’s arm (Cross Company). Sensors, grippers, brackets or any other tooling should be factored into the payload. If the payload is too close or equal to the robot’s maximum load capacity, it can degrade accuracy.

Orientation: How restrictive is the work area? That will determine if your robot needs to be mounted on the floor, overhead, etc.

Speed and travel: Vaughn says for pick-and-place applications, take into account acceleration times over significant distances. He says Cartesian robots, for example, can accelerate at 5m/sec or more and can be customized with belt, linear motor or ball-screw actuators to enhance their speed and distance.

Precision: Some robots are designed with predefined accuracy ratings while others can be upgraded with new linear actuators after they are purchased.

Environment: If the working environment is dirty or dusty, covers and high-performance seals are available for SACRA, articulated and Cartesian robots. Additionally, all robot types can be designed for use in clean rooms.

Duty cycle: This is the amount of time it takes for a robot to move out and back (Cross Company). Robots that run 24/7 reach the end of their service life sooner than robots running only eight hours a day, five days a week. Vaughn recommends purchasing robots with long lubrication intervals and low-maintenance requirements to avoid future issues.

igus® offers gantry, delta, and four and five-axis robots with self-lubricating components that are maintenance-free and resistant to dirt, dust, and corrosion. Visit igus.ca for more information.

Sources:

1.) https://www.machinedesign.com/motion-control/difference-between-cartesian-six-axis-and-scara-robots

2.) https://www.processsolutions.com/what-are-the-different-types-of-industrial-robots-and-their-applications/

3.) https://www.kellertechnology.com/blog/how-to-use-4-types-of-industrial-robots-to-your-advantage/

4.) https://www.linearmotiontips.com/what-is-a-cartesian-robot/

5.) https://www.crossco.com/resources/technical-bulletins-guides/robotics-101-6-axis-vs-scara-vs-delta-vs-collaborative/