Two drives in one: igus launches double-shaft stepper motor

By Michael Rielly

New motor for drylin linear axes ensures a space-saving and cost-effective drive for two mechanical loads

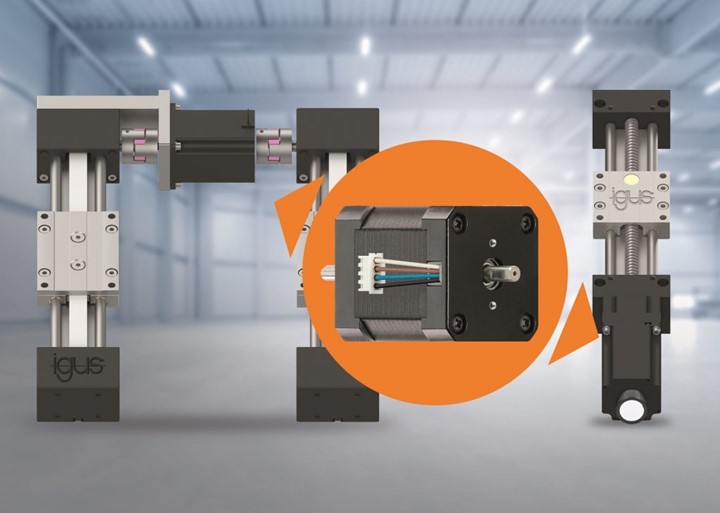

The versatile double-shaft stepper motor from igus enables two functionalities in one compact device. (Source: igus GmbH)

17 January 2023 – igus®, a major global manufacturer of engineered components that extend machine life, has developed a new double-shaft stepper motor for its drylin® linear technology. This innovation provides an easy introduction to automation solutions. The double-shaft design allows precise control over linear motion, enabling a range of automation, transfer station, and format adjustment applications.

Stepper motors move to precise designated positions in millimeter increments. This makes them uniquely suited for applications requiring accuracy and controlled motion. The new double-shaft stepper motor from igus enhances versatility and performance. Unlike traditional single-shaft versions, this innovative stepper motor has dual output shafts. The twin-shaft mechanism enhances precision across an array of automation technologies. It also expands possibilities for linear positioning systems like drylin solutions from igus.

“This design offers greater flexibility in the connection and drive of mechanical components,” explains Rene Erdmann, Head of the drylin E Business Unit at igus GmbH. “We can now drive two mechanical loads, such as two parallel linear axes, with just one motor.”

This saves space and reduces costs as the motor is available at the same price as a single stepper motor, and the user does not have to purchase a second coupling.

One motor, three functions

In contrast to conventional double-axis drives, where the motor is installed at the side and can cause space problems, the double-shaft stepper motor is located between the axes, making optimum use of the available installation space.

Another advantage of the double-shaft stepper motor is the option of mounting a hand wheel at the second shaft end. This means that the motor can also be turned by hand so that users can manually set the zero point of a linear axis.

In addition, they can adjust a self-locking lead screw axis manually by turning the hand wheel, for example, in the event of a power failure. This is particularly important in areas such as entrances or doors. Find out more here: https://www.igus.ca/info/n23-e-motors-stepper-motors-double-shaft