Designing a single-source linear system with drylin®

By Jared Worth

In industrial applications, achieving seamless, efficient, and reliable motion is essential. Often, this involves integrating a variety of linear motion components – from guides and bearings to actuators and motors. While it might seem logical to source individual components from different specialists, this approach can introduce unnecessary complexity, compatibility headaches, and ultimately impact performance and project timelines.

This is why igus offers the comprehensive drylin® product line of linear technologies designed to work together flawlessly. Complete drylin systems can unlock a range of benefits to help simplify your design process, accelerate deployment, and enhance the overall performance of your application.

drylin® linear technology

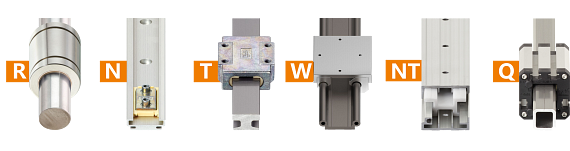

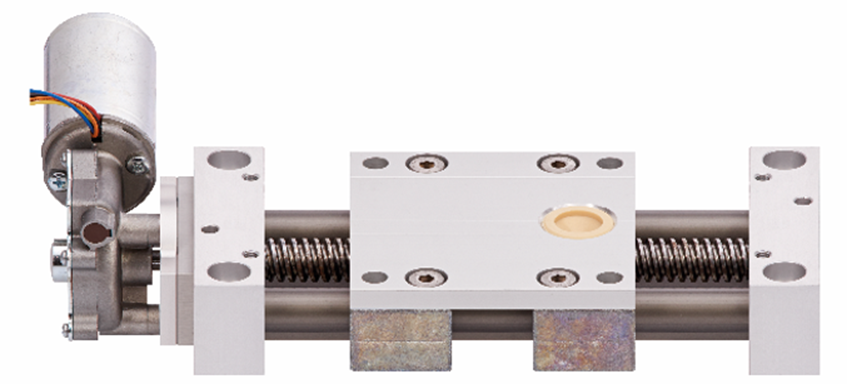

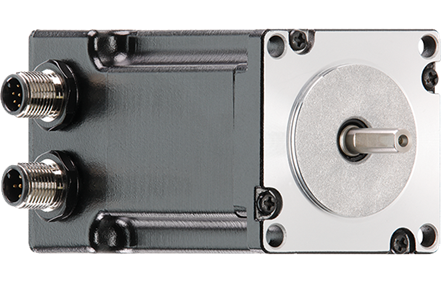

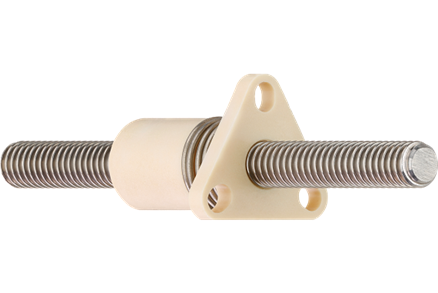

The drylin product line encompasses the core elements of most linear motion applications: linear guides and bearings, linear actuators, motors and motor controllers, motor connection cables, and lead screw assemblies.

- Linear Guides and Bearings: Six different rail geometries and dozens of liner materials with cost savings of up to 40% compared to competing products.

- Linear Actuators: Belt-driven and screw-driven linear actuators offering completely grease-free, maintenance-free operation.

- Motors and Motor Controllers: Stepper, DC, and brushless DC motors along with six different models of motor controllers and numerous accessories.

- Lead Screw Assemblies: Trapezoidal, ACME, metric, and proprietary high-helix lead screws with dry-running plastic lead screw nuts.

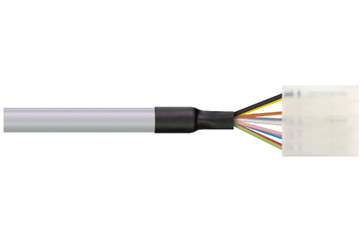

- Motor Connection Cables: Engineered for millions of cycles in dynamic applications, ensuring reliable power and data transmission to your linear systems.

While each of these components is a leader in its own right, they’re far more effective when they are designed and implemented as a complete system from a single source.

Meeting unique application requirements

The wide range of options available across the entire drylin product line ensures that no matter your application requirements, there’s a drylin solution for you. Whether you need an extremely fast system, one that can move loads of up to thousands of pounds, or one that’s accurate down to a fraction of a millimeter, there are drylin products that can meet these needs.

drylin systems are even suitable for environments with unique requirements like FDA compliance, extreme heat resistance, or even underwater use. And no matter the environment, you can receive accurate service life predictions through our online configuration tools.

Simplify design, ensure compatibility, and achieve plug-and-play operation

One of the most significant advantages of a unified product line is the inherent ease of use and plug-and-play functionality it provides. When components are engineered by the same manufacturer, they are designed with seamless integration in mind. This eliminates the guesswork and potential compatibility issues that often arise when mixing and matching parts from different vendors.

Imagine the time and effort saved when you don’t have to worry about:

- Ensuring mechanical interfaces align perfectly.

- Matching motor characteristics to actuator requirements.

- Verifying that control signals are compatible.

- Troubleshooting unexpected interactions between disparate components.

Our linear technologies are designed with standardized interfaces and optimized performance characteristics, allowing for straightforward assembly and configuration. This means faster design cycles, reduced engineering overhead, and quicker commissioning of your automation systems.

Thousands of combinations for unparalleled flexibility

A common misconception is that sourcing from a single provider limits your options. On the contrary, our extensive linear technologies product line offers thousands of possible combinations of guides, bearings, actuators, motors, cables, and lead screw assemblies. This vast selection ensures that you can configure a linear system that precisely meets the unique requirements of your application in terms of load capacity, speed, stroke length, accuracy, and environmental considerations. You gain the benefits of an integrated system without sacrificing the flexibility needed for specialized applications.

Streamlined support through a single point of contact

When you’re working with multiple suppliers for a single linear motion system, troubleshooting and obtaining technical support can quickly become a frustrating and time-consuming process. Pinpointing the exact source of an issue can involve navigating different customer service departments, each with varying levels of familiarity with the other manufacturers’ components in your system. This can lead to finger-pointing, delays, and a lack of clear accountability.

Choosing a single source for linear technologies eliminates this complexity. You gain a dedicated partner with in-depth knowledge of how every component in your system works together. This means:

- Faster Troubleshooting: Our support team understands the potential interactions and dependencies within a complete drylin linear system, allowing for quicker diagnosis and resolution of issues.

- Simplified Communication: You have one point of contact for all your technical support needs related to the linear motion system, eliminating the need to coordinate with multiple vendors.

- Accountability: With a single supplier for the entire system, there is clear accountability for the performance and reliability of the integrated solution.

This streamlined support model saves you valuable time and resources, minimizing downtime and keeping your operations running smoothly.

Integration with complementary technologies

igus’ product offerings extend beyond just linear technology. We offer other components like cable carriers and automation products that can also be integrated with our linear technologies to design even more comprehensive and sophisticated solutions.

- Cable Carriers: Provides secure and organized guidance for cables and hoses, protecting them from wear and tear and ensuring smooth operation.

- Automation Products: Includes gearboxes, gantries, robotic arms and more, which can be combined with our linear products to create multi-axis motion systems and complex robot cells.

By leveraging our broad portfolio, you can create a truly integrated application solution, simplifying procurement, reducing potential points of failure, and benefiting from unified support and expertise.

Invest in a system, not just components

By choosing the complete drylin linear technologies product line, you’re not just purchasing individual parts; you’re investing in a pre-engineered ecosystem designed for optimal performance and ease of integration. This approach minimizes risk, accelerates your time to market, and provides a foundation for building robust and efficient linear systems.