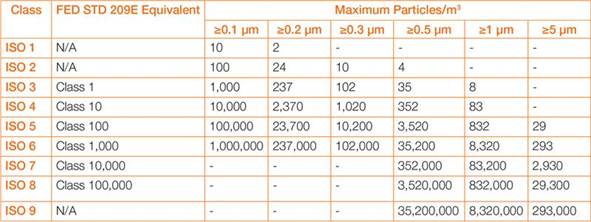

ISO classifications and standards for cleanrooms

Cleanrooms are essential controlled environments used in various industries to maintain specific levels of cleanliness. Their classification is based on the maximum allowable concentration of airborne particles per cubic meter.

Universal cleanroom standardization ensures product quality and safety, and is vital for everything from manufacturing microchips to compounding sterile drugs. The primary standards for cleanrooms are ISO 14644-1 and 14644-2. Prior to these, the FED 209E standard was used.

Table of Contents

- ISO 14644-1 vs FED 209E

- ISO Class 9

- ISO Class 8

- ISO Class 7

- ISO Class 6

- ISO Class 5

- ISO Class 4

- ISO Class 3

- ISO Class 2

- ISO Class 1

- Conclusion

- FAQs

ISO 14644-1 vs FED 209E

The FED 209E standard was first established in 1992, superseding a prior FED standard established in 1988. FED 209E remained in place until 2001, when International Organization for Standardization (ISO) 14644-1 and 14644-2 standards were first established. However, the FED 209E naming conventions of cleanrooms (Class 1, Class 10, Class 100, etc.) are still used even today.

While both of these standards classify cleanrooms based upon the max permissible particles within the cleanroom, ISO standards measure this in cubic meters, while FED standards use cubic feet.

Cleanroom classifications have expanded since the FED 209E standard was discontinued; the original FED 209E standard classified cleanrooms into six distinct classes, while ISO standards utilize nine classes — two cleaner than any of the FED classes, and one dirtier.

ISO Class 9 (Room Air)

ISO Class 9 environments, also referred to as “room air”, are the least controlled of all cleanroom environments. Class 9 rooms can have millions of particles per cubic meter, and are comparable to a standard office environment.

Per cubic meter, Class 9 cleanrooms allow:

- No more than 35,200,000 particles greater than 0.5 µm

- No more than 8,320,000 particles greater than 1 µm

- No more than 293,000 particles larger than 5 µm

These rooms are most often used either as a gowning room, or a buffer zone between uncontrolled environments and higher class cleanrooms to help maintain the integrity of the cleaner room.

ISO Class 8 / FED 209E Class 100,000

An ISO Class 8 cleanroom corresponds to FED 209E Class 100,000 and is the least stringent of the common cleanroom classifications. While it’s considered “dirtier” than the other classes, an ISO Class 8 cleanroom is still cleaner than room air by a factor of 10.

Per cubic meter, Class 8 cleanrooms allow:

- No more than 3,520,000 particles greater than 0.5 µm

- No more than 832,000 particles greater than 1 µm

- No more than 29,300 particles larger than 5 µm

Class 8 rooms are used in applications like pharmaceutical packaging, food processing, and some medical device assembly where basic contamination control is necessary. These rooms have 10 to 25 air changes per hour.

ISO Class 7 / FED 209E Class 10,000

Equivalent to FED 209E Class 10,000, ISO Class 7 cleanrooms are one of the most commonly used cleanrooms. They’re considered “mid-range” cleanrooms, and are used in printed circuit board (PCB) production, biotechnology, and various pharmaceutical applications. Most buffer rooms and gowning areas are Class 7.

Per cubic meter, Class 7 cleanrooms allow:

- No more than 352,000 particles greater than 0.5 µm

- No more than 83,200 particles greater than 1 µm

- No more than 2,930 particles larger than 5 µm

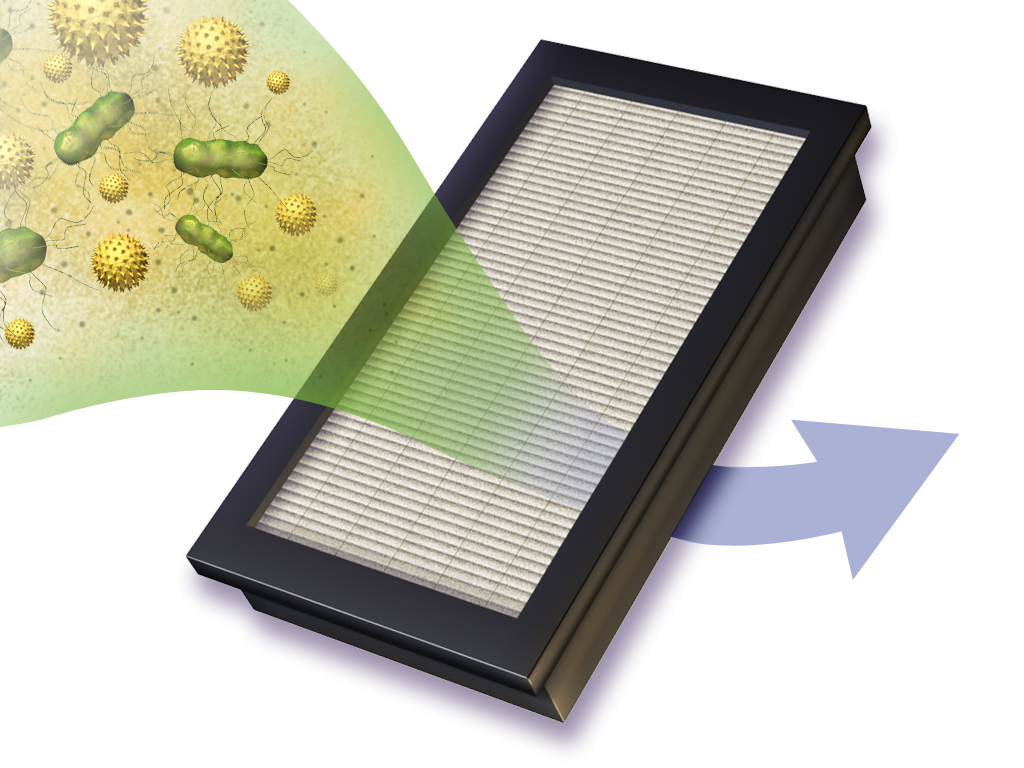

Class 7 cleanrooms utilize HEPA filters and 60 – 90 air changes per hour to maintain the required level of cleanliness.

ISO Class 6 / FED 209E Class 1,000

An ISO Class 6 cleanroom is a moderately clean environment that corresponds to FED 209E Class 1,000. It’s the lowest class that places limits on the number of particles smaller than 0.3 µm in size, as well as the lowest that can be used for semiconductor production — though higher ISO Classes are more common.

Per cubic meter, Class 6 cleanrooms allow:

- No more than 1,000,000 particles greater than 0.1 µm

- No more than 237,000 particles greater than 0.2 µm

- No more than 102,000 particles greater than 0.3 µm

- No more than 35,200 particles greater than 0.5 µm

- No more than 8,320 particles greater than 1 µm

- No more than 293 particles larger than 5 µm

These cleanrooms require 180 – 240 air changes per hour, which is achieved with air recirculation. Either HEPA or ULPA filters are used to remove particles like dust and bacteria from the air and maintain cleanliness.

Download the free White Paper!

ISO Class 5 / FED 209E Class 100

ISO Class 5 cleanrooms, equivalent to FED 209E Class 100, are a common standard for many critical manufacturing processes. They are widely used in pharmaceutical and medical device manufacturing for sterile product preparation, and in electronics manufacturing for components requiring significant particle protection.

Per cubic meter, Class 5 cleanrooms allow:

- No more than 100,000 particles greater than 0.1 µm

- No more than 23,700 particles greater than 0.2 µm

- No more than 10,200 particles greater than 0.3 µm

- No more than 3,520 particles greater than 0.5 µm

- No more than 832 particles greater than 1 µm

- No more than 29 particles larger than 5 µm

These rooms require between 240 – 600 air changer per hour and often feature unidirectional airflow to move contaminants away from work surfaces. If a Class 5 room is used for photolithography, specialized amber lighting is required to avoid exposing the photoresist.

Temperature and humidity requirements are also common starting at Class 5 cleanrooms depending on the specific application.

ISO Class 4 / FED 209E Class 10

Equivalent to FED 209E Class 10 cleanrooms, ISO Class 4 cleanrooms are highly strict environments. Per cubic meter, they allow:

- No more than 10,000 particles greater than 0.1 µm

- No more than 2,370 particles greater than 0.2 µm

- No more than 1,020 particles greater than 0.3 µm

- No more than 352 particles greater than 0.5 µm

- No more than 83 particles greater than 1 µm

ISO Class 4 cleanrooms are most often used in high-precision applications, such as the manufacturing of integrated circuits, micro-electromechanical systems (MEMS), and specific pharmaceutical processes like aseptic filling lines.

ISO Class 3 / FED 209E Class 1

ISO Class 3 is the strictest ISO Class with an FED 209E equivalent. The level of cleanliness in ISO Class 3 cleanrooms is critical for advanced precision applications like semiconductor fabrication, nanofabrication, and specialized biotechnology research.

Per cubic meter, Class 3 cleanrooms allow:

- No more than 1,000 particles greater than 0.1 µm

- No more than 237 particles greater than 0.2 µm

- No more than 102 particles greater than 0.3 µm

- No more than 35 particles greater than 0.5 µm

- No more than 8 particles greater than 1 µm

As many as 400 – 600 air changes per hour are required to maintain this level of cleanliness, and personnel need extensive gowning and preparation before entering the environment.

ISO Class 2

ISO Class 2 cleanrooms have no FED 209E equivalent, and are some of the cleanest possible manufacturing environments. They’re used in many of the same types of applications as ISO Class 1 rooms, albeit with less strict requirements.

Per cubic meter, Class 2 cleanrooms allow:

- No more than 100 particles greater than 0.1 µm

- No more than 24 particles greater than 0.2 µm

- No more than 10 particles greater than 0.3 µm

- No more than 4 particles greater than 0.5 µm

To maintain ISO Class 2 cleanliness, 480 – 720 air changes per hour are required, and laminar airflow is used to sweep particles away from critical work areas.

ISO Class 1

ISO Class 1 is the strictest classification of cleanroom. These are used for critical semiconductor and nanotechnology production, as well as specialized aerospace engineering. Even a single particle can cause catastrophic failure in these applications.

Per cubic meter, Class 1 cleanrooms allow:

- No more than 10 particles greater than 0.1 µm

- No more than 2 particles greater than 0.2 µm

A combination of an extremely high number of air changes per hour (500–750+) with an average airflow velocity of 0.305 – 0.457 m/s and the use of ultra-low particulate air (ULPA) filters is required to maintain the stringent requirements of ISO Class 1 cleanrooms.

Discover: ISO Class 1 energy supply systems

Conclusion

Cleanroom classifications, while not necessarily legally binding, are essential for maintaining the integrity of various products and processes across many industries and remaining compliant in those industries. These classifications, such as those defined by ISO 14644-1 and the now-superseded Federal Standard 209E, specify the maximum number of particles of a given size per unit of air volume.

Adherence to these standards, verified through regular testing and monitoring, is a fundamental requirement for quality control and regulatory approval in these sensitive fields.

Frequently Asked Questions

- HEPA or ULPA filters to provide a constant supply of clean air.

- Positive air pressure to prevent outside contamination.

- Specialized building materials that are non-shedding and easy to clean.