What Insects Can Teach Us About Linear Motion

Introduction

Nature has a way of solving engineering challenges long before humans do. Take insects, for example. Beetles, ants, and grasshoppers move efficiently using dry-running joints. These joints rely on microscopic surface structures and natural solid lubricants to minimize friction: no oil, no mess, just elegant design.

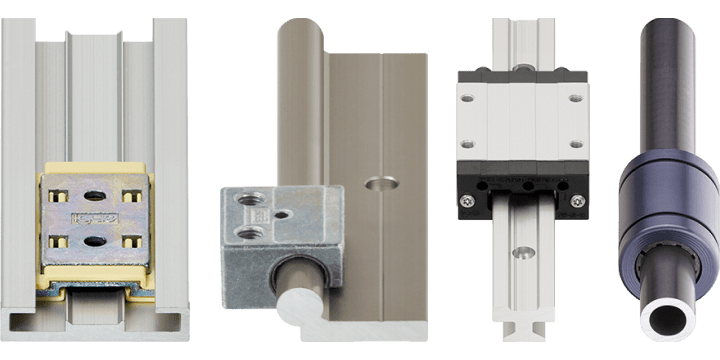

This principle of friction reduction without external lubrication mirrors the technology behind drylin® linear systems.

The Engineering Behind drylin

Traditional linear guides often use re-circulating ball bearings that roll along tracks. While effective, they require constant lubrication and can be vulnerable to dirt and corrosion. drylin takes a different approach. Instead of rolling, drylin systems slide. The sliding elements are made from high-performance, self-lubricating plastics that eliminate the need for grease or oil. This design not only simplifies maintenance but also ensures quiet operation and resistance to harsh conditions.

Performance Advantages

The benefits of drylin go beyond eliminating lubrication. These systems are shock-resistant, dirt-resistant, and corrosion-resistant, making them ideal for environments where reliability is critical. Their lightweight construction reduces overall system weight, while the absence of rolling elements minimizes vibration and noise. For engineers, this means fewer maintenance intervals, lower operating costs, and improved machine uptime.

Benefits at a Glance

- Shock resistant

- Dirt-resistant

- Corrosion-resistant

- Lightweight

- Quiet operation

- Self-lubricating

These features make drylin ideal for environments where cleanliness and reliability matter most.

Applications Across Industries

drylin technology is versatile. It’s used in food and beverage packaging, where cleanliness is non-negotiable. It powers camera and film equipment, where precision and silence matter. It thrives in marine environments, resisting corrosion from saltwater. It supports medical technology, where hygiene and reliability are paramount. Even in home office setups and gaming furniture, drylin delivers smooth, quiet motion without the hassle of lubrication schedules.

Why It Matters

Every moving part faces friction, and friction leads to wear. By removing external lubrication from the equation, drylin reduces failure points and simplifies maintenance. This approach saves time, cuts costs, and improves efficiency. It’s a solution rooted in nature’s simplicity but engineered for modern industry, a practical answer to a universal problem.

Conclusion

When nature solves friction with simplicity, we take note. drylin linear systems bring that principle into your machines, offering clean, efficient movement without compromise. Ready to learn more? Call 1-800-965-2496 or start a live chat at igus.ca.

Written by Shizu Yamaguchi, with the help of Copilot Generative AI to compose this from her original content