Case Study: How igus and Camosun College Helped a Candle-Making Business

By Shizu Yamaguchi

From Interior Design to a Small Business

After a decade as an interior designer and co-owner of a design firm, Bryn Milward stepped away from client work in 2020 to focus on raising her first child. But creativity has a way of finding its outlet. Inspired by her husband’s love for pure beeswax candles, Bryn began experimenting at home: melting wax, dipping tapers, and sourcing local materials.

By 2024, her business, Little Mill, was ready for launch. Yet one challenge loomed large: dipped taper candles, her most popular product, were also the most time-consuming to make. Scaling up seemed impossible, until a conversation over Thanksgiving changed everything.

The Spark: A Machine to Make It Possible

When Bryn mentioned the painstaking process to her brother, his response was immediate: “I could make a machine to help with that.” His prototype didn’t quite work, but it led Bryn to Camosun College, where engineering students took her idea and turned it into reality.

What began as a simple wish became a full-scale design project, one that would transform her business. And thanks to Camosun’s participation in the igus YES (Young Engineers Support) Program, the team had access to free igus parts and technical assistance to bring the concept to life.

Engineering Meets Ingenuity

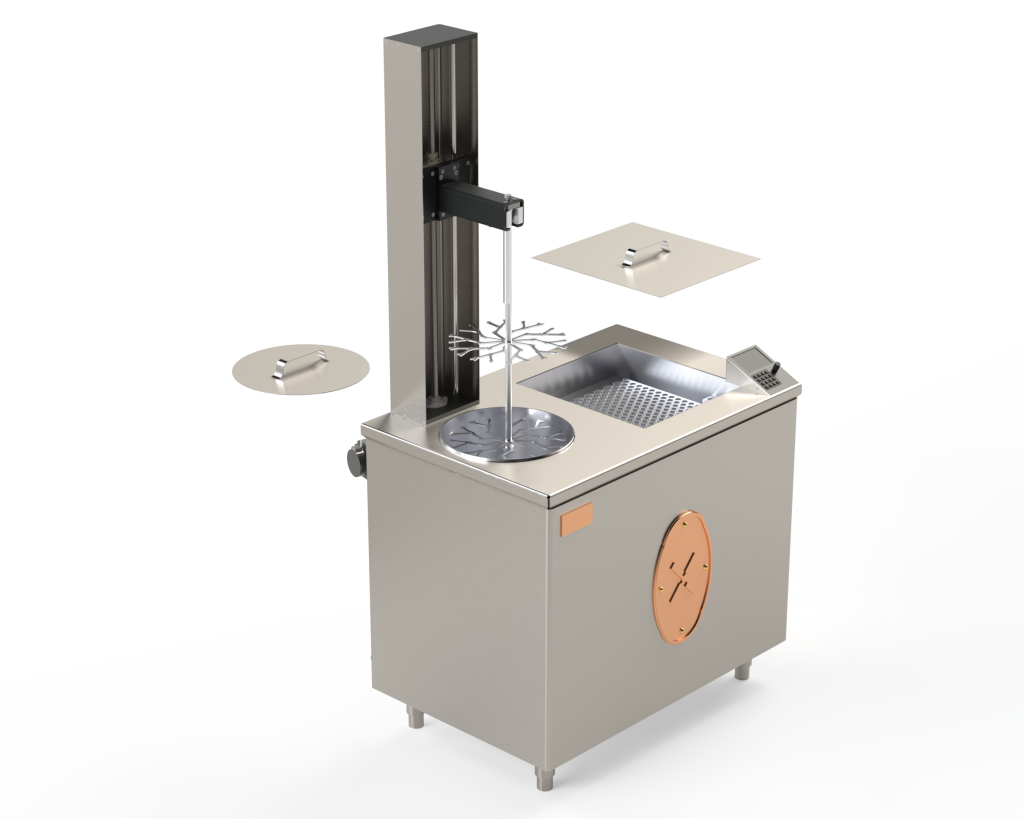

Working with Camosun’s team was a revelation. “I shared my vision, and they figured out every step needed to make it happen,” Bryn recalls. From deep research into beeswax to designing an automated dipping system, the students approached the challenge like seasoned professionals.

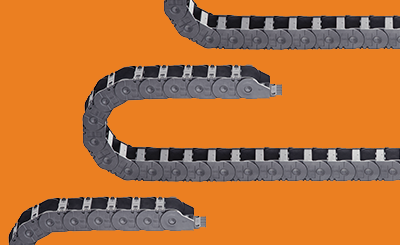

Bryn even contributed her own design expertise, shaping the machine’s industrial yet elegant look. igus brought the mechanics: smooth, reliable motion powered by their polymer bearings, linear guides, and multi-start lead screws. These components were chosen for their durability, precision, and maintenance-free performance.

Why It Matters

Before the machine, Bryn’s process meant hours of supervision over propane heat, limited production in cold weather, and constant juggling between candle-making and family life. Bringing in the automated candle-dipping machine allowed her not only to melt wax safely and dip tapers consistently, but it freed her to focus on other aspects of her business, such as packaging, marketing, and design. And with the ability to create candles at a faster rate, she was able to scale up her business by entering further into the wholesale market.

The igus Advantage

Through the YES program, igus empowers students and innovators to turn ideas into reality by providing free motion plastics and engineering support. For Bryn, that meant a machine that could grow her business and free up her valuable time. For others, it could mean automation solutions, custom designs, or entirely new products.

If you’re an entrepreneur, engineer, or manufacturer looking to innovate, igus is ready to help you build what’s next.

Have an idea that needs motion? Learn more about the igus YES program and explore components for your next project. Contact igus today to start your journey.

Edited with the assistance of AI tools to ensure clarity and flow.