Repair of an vintage car speedometer with the help of 3D printing service

Guest author: Dr. Jörg Pühler | 18. April 2019

Restoring a 1924 Stanley 750B Speedometer with 3D Printing

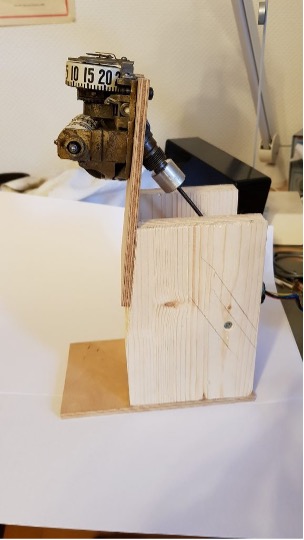

The mileage counter on my 1924 Stanley 750B speedometer had stopped working. This unit, a Stewart-Warner M-9 model from Chicago, required a closer look to diagnose the issue.

Failure Analysis

After dismantling the speedometer, the problem was immediately clear: the gear on the first intermediate shaft, responsible for meshing with the worm on the input shaft, was completely destroyed. The pinion no longer engaged with the worm, and previous attempts at “repair” had only worsened the situation, making accurate measurements impossible.

Sourcing Spare Parts: A Modern Approach

Reproducing the damaged gear using traditional methods was beyond my capabilities. While searching online, I discovered that igus offers custom gear production via SLS 3D printing using a specialized material. However, this process requires a precise STEP file of the component, which meant creating a 3D model first.

From CAD to Component in Days

Using FreeCAD, an open-source design tool with excellent online tutorials, I was able to model the gear in just two evenings. The rest of the process was remarkably simple: upload the file, review the instant price quote, place the order, and wait for delivery.

The printed part exceeded expectations. The material was strong, and even the smallest details were reproduced accurately. The shaft fit perfectly into the bearings, and the worm gear aligned precisely. My only mistake was underestimating the wear on the original pinion, resulting in a gear that was slightly undersized. Fortunately, one of the advantages of additive manufacturing is easy iteration, and adjusting a single parameter in the CAD model allowed me to quickly produce a corrected version.

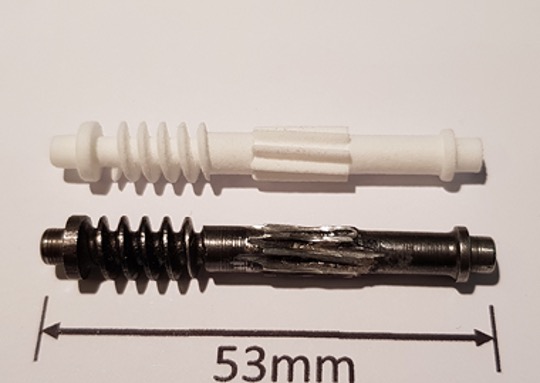

Comparing Original and Replica

Side by side, the original metal gear and the 3D-printed replacement demonstrated impressive precision. While the printed surface felt slightly rough, the bearing journals exhibited minimal friction in the metal bushings. The second version performed well during a short endurance test, though it was slightly uneven at low speeds. After fine-tuning the gear diameter (module) and helix angle, the third iteration ran perfectly.

Material Performance: iglide® I6

The replacement gear was printed in iglide® I6, a self-lubricating, wear-resistant polymer. No additional lubrication was required, and after 2,000 miles of operation, there was no noticeable wear. Minor traces of metal abrasion appeared early in testing but did not progress over time. For components like this, laser-sintered 3D printing with high-performance polymers offers a cost-effective, durable solution, provided the 3D model is accurate.

Investigating Gear Wear

Before the endurance test, I examined the speedometer for underlying causes of gear failure. The issue originated in the three-digit daily counter: the dials had approximately 0.2 mm of axial play, and no spring washer to maintain pressure. During testing, a small transfer gear occasionally slipped between the dials, jamming the counter. Adding a slightly bent 0.1 mm brass shim eliminated the clearance and resolved the blockage.

The speedometer itself was functional but displayed speeds 15–20% below actual values. This discrepancy was due to the steel magnet losing strength over decades. While the built-in adjustment mechanism could slightly alter magnetic flux, it was insufficient for full correction. Re-magnetizing the magnet wheel was necessary. Ideally, this requires an electromagnet capable of delivering a strong pulse, but I achieved satisfactory results using several small neodymium magnets. After calibration, the speedometer displayed accurate readings up to 55 mph, with minor deviation above that.

Conclusion

The successful restoration of this vintage speedometer demonstrates how 3D printing and modern materials can breathe new life into century-old mechanical systems. With accurate CAD modeling and the right polymer, additive manufacturing provides a practical, efficient alternative to traditional machining, especially for complex or obsolete components.

This article was re-written with the assistance of Copilot Generative AI.