Understanding igus Linear Guides: A Beginner-Friendly Overview for Mechanical Engineers

igus offers a wide range of linear motion products, and for engineers who are new to the brand, the product names can feel unfamiliar at first. Each igus drylin® product family addresses a specific type of linear motion requirement, and all of them operate with self‑lubricating plastic bearings. This means they run without grease, avoid contamination issues, and require very little maintenance.

drylin W: our flagship linear rails product

drylin W is the most versatile of the igus linear guide systems. Our flagship drylin product consists of a highly modular rail and carriage platform that can be configured in many ways. Engineers choose drylin W when they need flexibility in materials, rail shapes, lengths, and mounting styles.

drylin N for small installation spaces

drylin N is designed for extremely tight installation environments. Its low-profile rails are ideal for compact machines, small automation systems, and enclosures where vertical space is very limited.

drylin T as replacement for recirculating ball bearings

drylin T is intended for engineers who currently use recirculating ball bearing guides. The dimensions are similar to many traditional ball-rail systems, which allows for straightforward upgrades without major design changes. Engineers who want to improve reliability or reduce maintenance often move to drylin T because it eliminates lubrication and is less sensitive to dirt.

drylin R for round shafts

drylin R is igus’ line of shaft-guided linear bearings. These bearings fit standard round shafts and can replace bronze bushings or linear ball bushings directly. Instead of rolling balls, drylin R uses polymer liners that glide smoothly along the shaft.

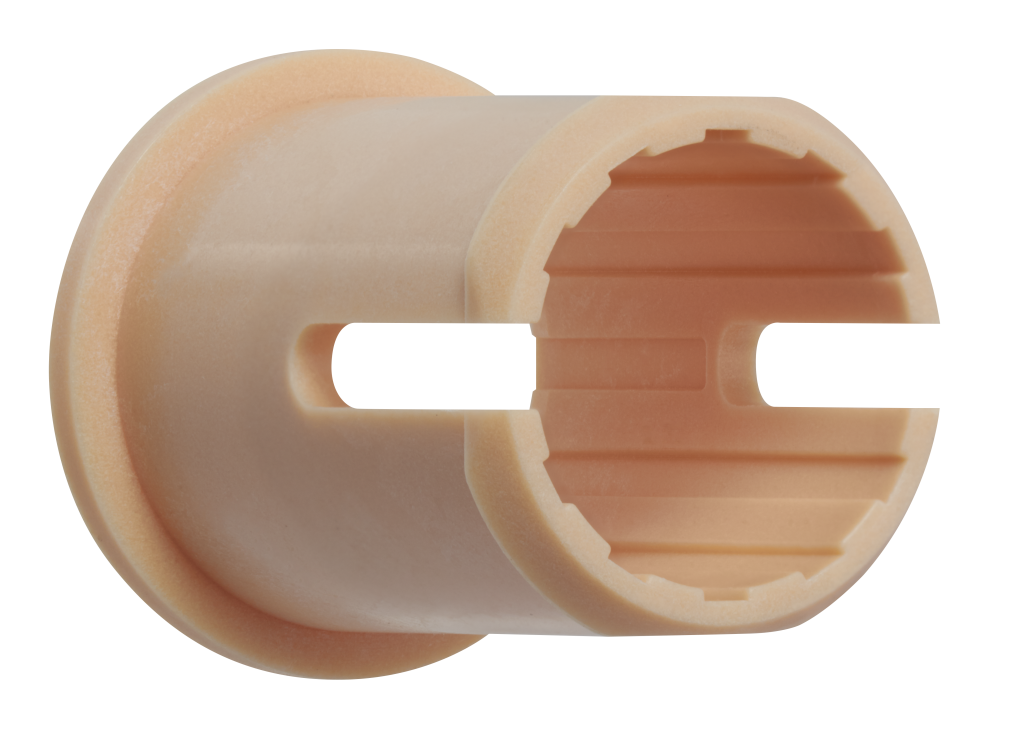

JUCM: A Compact drylin R bearing for tight Spaces

Some machine assemblies, especially in packaging, food processing, and beverage equipment, offer very little room for linear motion components. The JUCM bearing from the drylin R family is designed specifically to address these space limitations. It provides linear guidance using a compact profile that mounts directly into sheet metal structures.

The JUCM bearing is installed entirely by hand, and its geometry allows it to snap securely into place without the need for axial securing hardware. This makes it an efficient option for engineers who want to reduce installation time or simplify assembly steps.

The bearing uses an iglide J liner, which supports low-friction, lubrication‑free movement. This material performs well in applications that require smooth, quiet operation and where contamination from grease must be avoided.

Additional dimensional data, technical specifications, and CAD files are available at:

https://www.igus.ca/product/drylin_JUCM

Questions?

We’re available at 1-800-965-2496, via live chat at www.igus.ca, by email at CAOrdersNA@igus.net, and contact form.

We’d be happy to assist you with our unique problem solvers.