The critical role of grease-free plastics in sterile environments

By Jared Worth

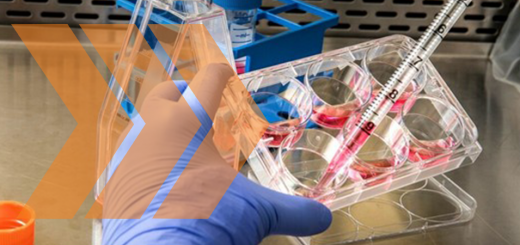

Sterile environments are critical across various industries, from food and beverage processing to medical and biotechnology manufacturing. In these settings, ensuring cleanliness and preventing contamination are the top priorities.

Traditionally, metal components have been used in sterile environments, but they’re not always the best choice. Dry-running, maintenance-free plastics from igus offer a superior solution to metal, while still meeting the stringent requirements of sterile applications.

Requirements & conditions in sterile environments

Sterile environments are subject to strict requirements and conditions to prevent contamination, making them a critical consideration across various industries. In the food and beverage sectors, components must adhere to FDA compliance standards to ensure product safety. This often means that materials must be non-toxic, easy to clean, and resistant to environmental factors.

Beyond general cleanliness, components must also withstand rigorous cleaning processes. This includes frequent chemical washdowns, which can involve high-pressure water and corrosive cleaning agents.

In medical, biotech, and manufacturing applications, parts may also need to endure autoclaving. This sterilization method uses high-temperature pressurized steam, requiring materials to be resistant to heat and moisture to prevent warping or other damage.

Sterile igus components for a range of applications

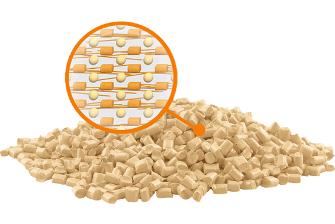

igus offers a wide variety of dry-running, maintenance-free sterile components for numerous applications. These include:

- Bearings and rollers: Self-lubricating bearings and rollers that are ideal for conveyors and other moving parts.

- Actuators and gantries: Precision components for automated components that require sterile operation.

- Lead screw assemblies: Essential for both manual and automated precision motion control.

- Slewing rings: Components that allow for rotational motion with clean, maintenance-free operation.

- Cable carriers: Safely and reliably manage cables in motion systems while extending cable service life.

- 3D printing filament & bar stock: Create custom components while retaining the key benefits of igus’ sterile materials.

Key advantages of sterile plastic components

Dry-running plastics offer many invaluable advantages in sterile applications. Learn more about these advantages below.

Eliminates grease contamination

Because dry-running plastics do not require grease, they eliminate the risk of contaminating food, beverages, or other sensitive products, providing a major advantage over traditional metal parts. This also eliminates a majority of routine maintenance.

Resistant to washdowns and autoclaving

Equipment in sterile environments must endure rigorous cleaning processes. Many igus components are resistant to both chemical washdowns and high-pressure water. They can also withstand autoclaving, with numerous materials that are able to handle the over 121°C temperatures without issue.

FDA-compliant and safe

igus offers products in nearly every major product line that are FDA-compliant. This makes them suitable for use in food, beverage, and packaging applications, and safe for direct food contact. Additionally, most iglide materials are PTFE-free, and have been tested for 96 of the most important PFAS substances to ensure they meet stringent safety requirements.

White Paper: PFAS in focus: Planned restrictions, challenges, and solutions for the industry

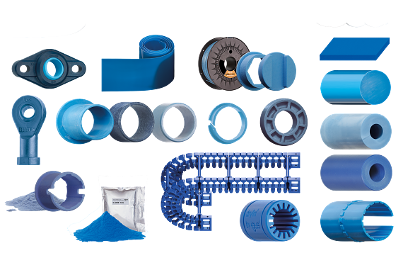

Visibility and detectability

FDA-compliant products from igus are colored a highly visible blue. This helps aid visibility and ensure foreign objects can easily be spotted during visual inspections. Some materials are also metal-detectable, providing an extra layer of safety in production lines by allowing for the detection and removal of fragments broken off from components.

Conclusion

While metal components are still a popular choice for applications in sterile environments, high-performance plastics from igus are a superior solution in most cases, due to their grease-free performance, resistance to washdowns, and FDA compliance.