Why do bearings move out of their housing?

By Lars Butenschon

In order to ensure that a bearing stays within its housing properly, users must either better secure the bearing or change the bearing material.

What causes bearings to move out of their housing?

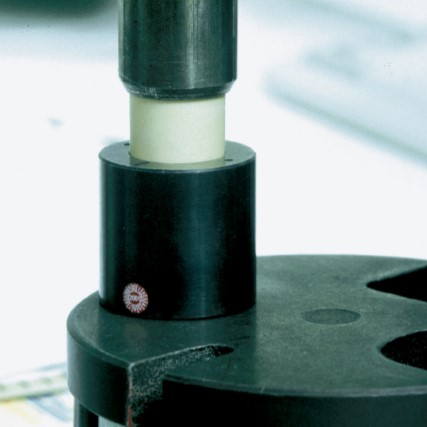

Typically, plain bearings are installed with an arbor press. The holes they are fit into are slightly smaller than the outer diameter of the plain bearings. Therefore, the bearing is kept in place by mechanical tension. If this tension is lower than the push out force generated by the load and movement of the pivot point, the bearing will move out of the mounting hole.

Bearings that move in the housing bore do not automatically fall out of it completely. If they cannot move axially, they can still rotate. This can lead to squeaking and decreased overall running performance. The worst case is, of course, a bearing that exits the housing completely, resulting in the shaft and housing scraping against each other and leading to significant wear.

Two reasons for loss of press-fit are high temperatures and high loads. If the temperature in the bearing rises above a certain threshold, the bearing can start to loosen, as mechanical tension cannot be maintained. The other cause for loss of press-fit is an overly high load over prolonged periods. This load is a material-specific value and the situation described is referred to as “creeping” (defined as a slow process of deformation of material due to high loads).

High temperatures or loads will not always lead to system failures. The specific load-to-surface ratios and temperatures requiring specific materials or additional axial securing vary based on the plastic material and compound.

Another more inconsequential (but actually more frequently encountered) issue can be the housing bore being out of tolerance. If the press fit-is too loose due to an oversized housing bore, the likelihood can increase that the bearing will move out of the housing.

What can we do other than selecting another material type?

To make life easier, some manufacturers of plastic plain bearings provide recommendations on how much surface load a bearing can take, as well as acceptable temperature ranges within which bearings will stay in place.

Conclusion: Careful material selection and strategic design are vital for securing bearings against moving out of their housing bores. Different design choices for securing bearings are covered in part two of this series.