Chainflex® Cables Used In Industrial Robots

By Sascha Mais

In recent articles, we have looked at how chainflex® cables are used in storage and retrieval units and in crane systems. Today we take a closer look at the topic of robot applications, since igus® is not only market leader in the field of cables for the energy chain, but also offers a wide range of cables for robot applications with the CFROBOT family.

Robot cables at igus®

The rapid development of the industrial robots has resulted in high demands for the robots and their robotic components. These include robot cables, which are used in both energy chains and robots. The robot cables must meet the high requirements and withstand the rapid development. Our chainflex robot cables do that.

Before a robot cable is allowed to carry the name chainflex®, the durability of the cable is tested several times in our laboratory. The cable is pushed to its technical limits to determine durability and maximum load.

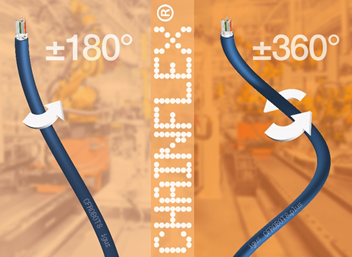

The hurdle for a genuine CFROBOT is a guarantee statement. It is allowed to bear the name CFROBOT only after the service life of a cable has been proven in our test laboratory and the cable has completed 5 million cycles with ± 180°/m. Robot cables are often used in production lines. The failure of such a cable often means that the entire production comes to a standstill. High quality is therefore indispensable.

The igus® portfolio of cables for robot applications is large. The product range includes control cables, data cables, measuring system cables, fibre optic cables, motor cables, single cores, bus cables and even hybrid cables. Every year we expand our product portfolio in order to meet the constantly growing market.

Requirements for cables in robot applications

The difference between robot cables and cables installed in a static cable carrier lies in the structure. In cables for linear e-chains, the “mechanical stress” only occurs in one direction. However, cables in robotic applications must be able to withstand the constant torsional movements that occur during operation. These twists of the cables are sometimes considerable and can reach up to ± 360°/m. Special demands are made on the braided shielding here. For this, torsion-optimized shield structures are chosen that can carry out the necessary compensatory movements thanks to special PTFE liners. As with all chainflex® cables, the service life of the CFROBOT cables can be precisely determined. Unexpected breakdowns are a thing of the past, because even a potential replacement of the cable can be planned perfectly.

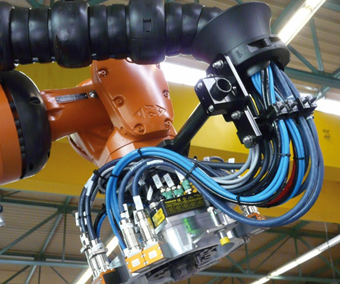

igus® e-chain cable carrier on a robot in automotive body construction

Clean guidance for robot cables

Corrugated hoses whose durability is limited are often used here. To optimally guide and protect the cables on the robot, igus® offers the triflex series, the suitable energy chain for robot applications. These energy chains were specifically developed for robotic applications and offer high flexibility with clear radius stop-dogs and high tensile force absorption. Compared to a cable protection hose, triflex energy chains offers a defined bend radius, which greatly increases the service life of cables and hoses.

You can also obtain the individual components from us as a dress pack. We call the pre-assembled igus system, readychain. And to round it all off, we offer you an individual “all-round carefree package” with the igus installation service.

Conclusion

In addition to great variety, the chainflex® cable range also offers you planning reliability in the selection of the right cable. And as with all chainflex cables, igus offers you a guaranteed service life of 36 months for the robot cables.