What is a Lead Screw?

By Shizu Yamaguchi

Introduction

If you have made it here, you are likely wondering what a lead screw is. And you may have some questions about pitch, lead, starts and thread types. In this blog post, we will cover those topics and also list out some advantages and disadvantages of lead screws, show how they compare to ball screws, and describe how to select the lead screw that’s right for you. Let’s get started.

Lead Screw Definition

A lead screw is one part of an assembly that translates rotary or turning motion into linear motion. The assembly is usually a screw shaft combined with a nut to provide power transmission. Alternative names include power screw or translation screw.

Lead screws differ from threaded rods in that its purpose is the transmission of power rather than fastening. Because of this difference, the shape of a lead screw thread is not v-shaped or isometric. These shapes lead to more friction, which is desirable in fastening but not when threads are made to allow for motion.

Common Applications

Lead screws are often used in linear actuators, machine tools, screw jacks, presses and vises.

Lead screws are also found in biomedical environments such as clinics and hospitals. For example, lead screws are used in pumps for blood and drugs requiring precise fluid measurement and fluid delivery. They are also used in lab testing equipment such as devices that sample, scan and handle fluid.

Other popular industries in which lead screws are used include defense, transport and industrial automation.

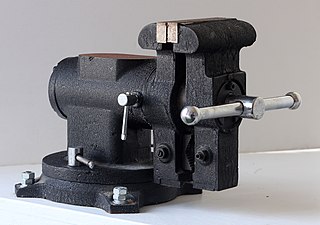

Fig. 1: A vise.

Photo: “An engineer’s vise” by Dmitry Makeev, licensed under Attribution-Share Alike 4.0 International (CC BY-SA 4.0)

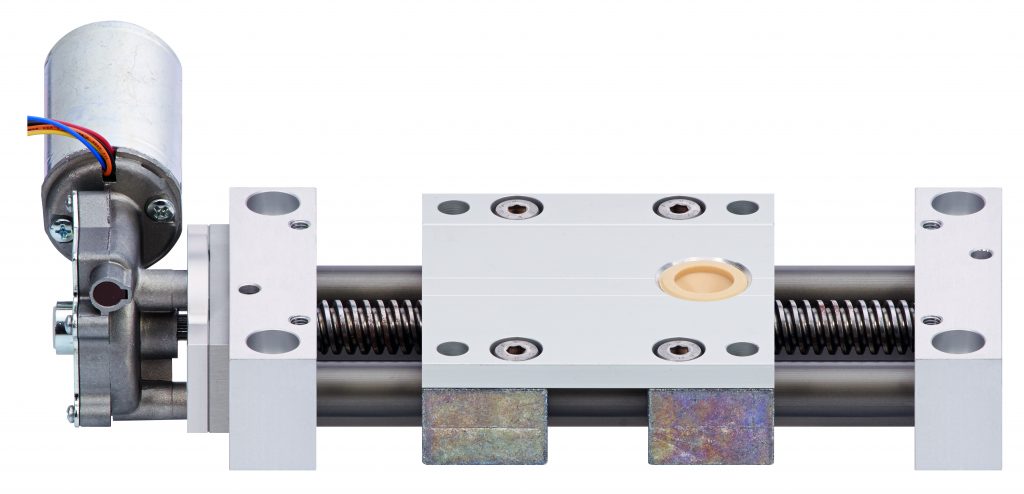

Fig. 2: Drylin® linear actuator with lead screw

Fig. 3: The lead screws permit the opening and closing of the door on the Boeing 747.

Photo: Own work by Olivier Cleynen, Attribution-Share Alike 3.0 Unported (CC BY-SA 3.0)

Thread Types and Their Purposes

There are many kinds of lead screw threads, each with a different shape and purpose.

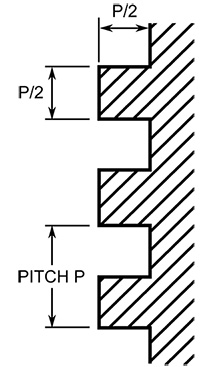

Photo: “English: The square thread form” by Wizard191, licensed under Attribution-ShareAlike 3.0 Unported (CC BY-SA 3.0)

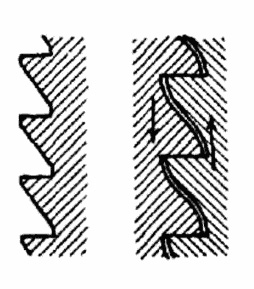

Square threads have the least amount of friction, making them the most efficient (Efficiency is the capacity to transfer torque to thrust while keeping mechanical losses to a minimum). However, they are also the most difficult thread to manufacture, which means they’re the most expensive. Square threads are usually used for high power applications.

Buttress threads are very much like square threads, except half of the thread is cut off. They each have the same efficiency but buttress threads can only be used unidirectionally.

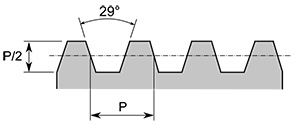

Trapezoidal threads include both ACME and trapezoidal metric threads. They are able to handle loads in both directions; however, they are less efficient than square threads. Trapezoidal threads are also able to handle high axial loads. These threads, because of their manufacturing ease and load handling, are very popular.

Photo: “English: Dimensions of an Acme thread” by (derivative work of) Wizard191 (original author: Zielu20), licensed under Attribution-ShareAlike 3.0 Unported (CC BY-SA 3.0)

ACME threads are measured in inches and they have a 29 degree thread angle. The thread height is half of the pitch.

Trapezoidal metric threads are similar to ACME threads but are measured in millimeters and have a 30 degree thread angle.

Other thread types include sharp, course, knuckle and diamond threads.

Screw Pitch and Lead

The screw pitch is the distance from the peak of one screw thread to the next screw thread. This term is often used with inch-sized products such as ACME threads and is usually designated as threads per inch.

Lead screws have two types of motion involved, linear (of the nut) and rotational (of the lead screw). The screw lead is the linear distance the nut makes for every complete screw turn. This is typically how ball screws are designated.

For single start screws, the pitch and lead are equal to each other. For multiple start screws, the pitch multiplied by the number of starts is equal to the lead.

Starts

Each thread has a corresponding start. The starts can be counted at the top of the lead screw, where the beginning of every thread begins to wrap around the screw shaft.

Some lead screws have only single starts, which is one thread that runs the entire length of the screw. Other lead screws have multiple starts – that is, two or more threads that run the entire length of the screw.

For example, if a lead screw has four starts along the length of the screw, there would be four threads that wrap their way around one after the other in a 1-2-3-4 pattern. In such a lead screw, any one start would show up every four threads.

For a great visual on single starts versus multiple starts, please click here.

How Lead Screws are Made

Threads on lead screws are either rolled, ground or cut/machined. Ground lead screws are both the most expensive and highest performing.

Lead Screws vs. Ball Screws

Ball screws and lead screws are similar components. They both convert rotary motion into linear motion in a very similar way. The difference is that while the lead screw has the nut slide over the shaft, the ball screw has the nut roll over the screw shaft via a recirculating ball mechanism.

Ball screws are very accurate and have a high efficiency. The lifespan is highly predictable and can be used in high-speed applications. However, the parts are more complex and therefore more expensive to make. They are also more noisy than lead screws.

Lead screws have certain advantages and disadvantages over ball screw assemblies.

Advantages of Lead Screws

- High load carrying capacity

- Compact

- Easy to design

- Easy to manufacture – specialized machinery is not needed

- Accuracy and precision in motion

- Low-maintenance, quiet and smooth operation

- Fewer number of parts

- Majority are self-locking and cannot be back-driven

Disadvantages of lead screws

- Not very efficient

- Not for use in continuous applications

- Large amount of friction on threads, leading to quicker wear

- Required to replace the nut of square threads (a split nut can be used for compensation of the wear on trapezoidal threads)

Factors When Selecting a Lead Screw

There are a few things to consider when choosing a lead screw. The two most critical factors are the screw pitch and lead. These determine the performance of the lead screw.

Speed is another important factor. Lead screws have an upper speed limit, a limit to the rate of rotations. Going over this limit leads to vibrations in the lead screw. Lead screws are appropriate for low-duty applications in the range of 10 rotations per second.

Accuracy is another factor to consider. This factor is defined by how close to a goal end point the system can move a load within a certain tolerance. The lead screw accuracy affects the entire system accuracy.

Repeatability is also important. Repeatability is how well a lead screw system can move a load to the same position repeatedly.

igus® offers both Trapezoidal and ACME screws, in addition to its own high helix screws with a proprietary design. Various plastic nut versions are also offered. You are welcome to visit www.igus.ca for more information. We are also available at 1-800-965-2496 and orders@igus.com.

References:

https://www.powerjacks.com/about-us/how-a-lead-screw-works

https://en.wikipedia.org/wiki/Leadscrew

https://www.thomsonlinear.com/en/support/tips/difference-between-screw-pitch-and-lead

https://www.sciencedirect.com/topics/engineering/lead-screws