How does 3D printing reduce waste?

By Jared Worth

3D printing is one of, if not the hottest topic in manufacturing today, and for good reason. It’s opened up entirely new ways of thinking about solutions to problems that arise, and does so while generating relatively less waste than other manufacturing methods such as CNC machining. But can 3D printing become truly sustainable? This blog will discuss some of the benefits and drawbacks to 3D printing, and how those can affect the potential for sustainable 3D printing solutions.

Additive Manufacturing vs. Subtractive Manufacturing

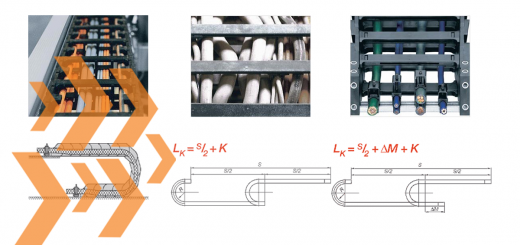

Additive and subtractive manufacturing are both common terms in the space, but what do they mean? Simply, additive manufacturing (3D printing) is manufacturing that adds materials layer by layer to create a part, and subtractive manufacturing (machining) starts with a stock piece of material and cuts away the excess to create a part.

Additive manufacturing is ideal for prototyping or otherwise small-scale production, as well as creating highly complex parts or parts with a hollow structure. It’s also much simpler to create parts via additive manufacturing, since less tools are needed overall.

Subtractive manufacturing is better for large batches of parts, but is generally limited to less complex parts than additive manufacturing can create. Machined parts are also typically better for high-stress applications and tight tolerances.

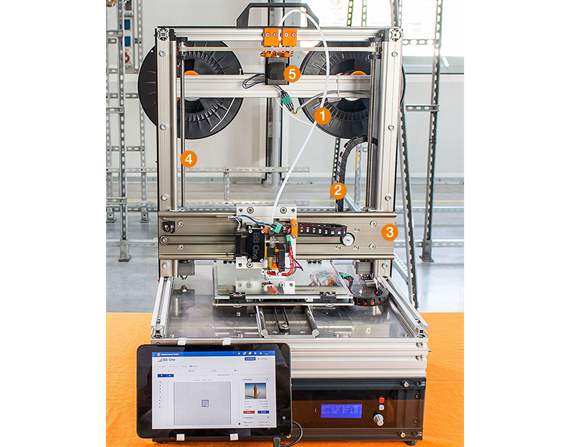

Material Recycling

When it comes to recycling, additive manufacturing has the clear advantage. Fused deposition modeling (FDM) is the most common type of 3D printing and currently offers the most robust recycling potential. FDM printers can take single-use plastics – for example, water bottles – and recycle them into raw materials suitable for printing. Other biodegradable materials, such as coffee grounds and even wood, have found some use as 3D printing materials when combined with a polylactic acid (PLA) base, but with much less frequency.

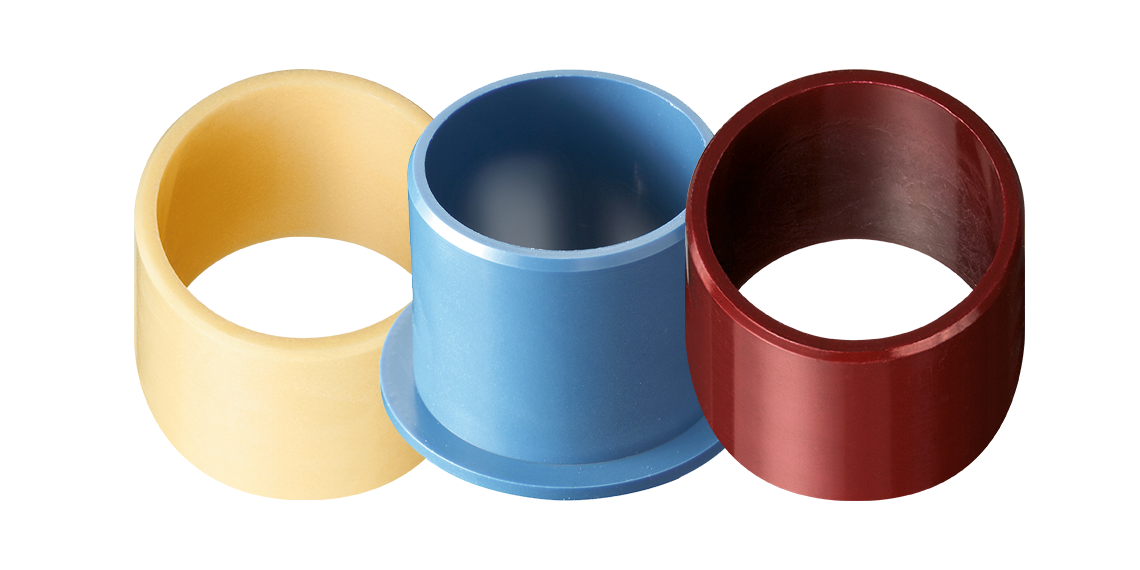

Though not exactly recycling, 3D printing serves another key function to reduce waste and allow for the reuse of machines and vehicles that may otherwise need to be scrapped. Old parts that are no longer produced can easily be 3D printed with minimal lead time. The new part can even outperform the original, as was the case with a rudder bearing replacement for a sailboat igus® printed for a customer who could no longer obtain the part from the original manufacturer. The new part was cheaper and offered better steering function than the original.

Material Waste

One of the biggest issues with both additive and subtractive manufacturing is the amount of waste generated that simply can’t be recycled. In additive manufacturing, processes like selective laser sintering (SLS) and stereolithography (SLA) leave behind waste in amounts of up to 50% of the original material.1 Even still, the waste generated by 3D printing is on average 70-90% less than waste generated by subtractive manufacturing methods.2

Another source of waste when considering additive manufacturing is the use of supports in the printing process. These supports are essential, as without them the part would fail before it’s even done printing, yet they’re one of the biggest contributors of waste as they are currently not reusable and thus are thrown out after the print is complete. Research is being done into potential reusable support solutions, which could reduce material usage by about 35%.3

Flexibility

The least readily apparent advantage additive manufacturing has over subtractive is the flexibility it offers. For example, most 3D printers (excluding certain types such as SLS printers) are much smaller than CNC machines so they’re easier to implement in office and home spaces. This added flexibility contributes to less need for large material shipments often used for subtractive manufacturing, cutting on the C02 emissions generated.

Emissions generated directly by subtractive manufacturing methods are also a concern. Being larger machines, they naturally generate more emissions, not to mention are much louder than 3D printers. This makes establishing subtractive manufacturing facilities in densely populated areas, where they would be of most use, much more difficult and damaging than additive manufacturing facilities.

Conclusion

Ultimately, there’s no single right answer when it comes to sustainability in manufacturing. Both additive and subtractive manufacturing have their own set of benefits and drawbacks. 3D printing as a whole generates less waste and emissions than machining, but machining is still a necessary component of manufacturing that likely isn’t going anywhere anytime soon. A hybrid solution that takes advantage of both forms of manufacturing is ideal, at least until more advances are made in the 3D printing space.

Looking to speak with an expert about the igus 3D print service, or potential applications for 3D printed parts? Contact us here, or call us at 800-965-2496

Sources:

2 Azom