Shaft considerations for bearing applications part 1: hardness

By Nick Van Tol

When it comes to deciding which shaft/pin solution is best for your application there are a lot of factors to consider; type of steel, machinability, surface and core hardness, surface roughness, availability, price, corrosion protection, retention features, etc. While these aspects are nothing new to the design phase, they are becoming even more important as we move away from traditionally greased bearings to dry running, maintenance free bearings. We will discuss the most important topics for bearing performance over a series of 3 blogs; surface hardness, surface roughness, and corrosion resistance. First up, a brief story from the agricultural industry on shaft hardness.

In the Field

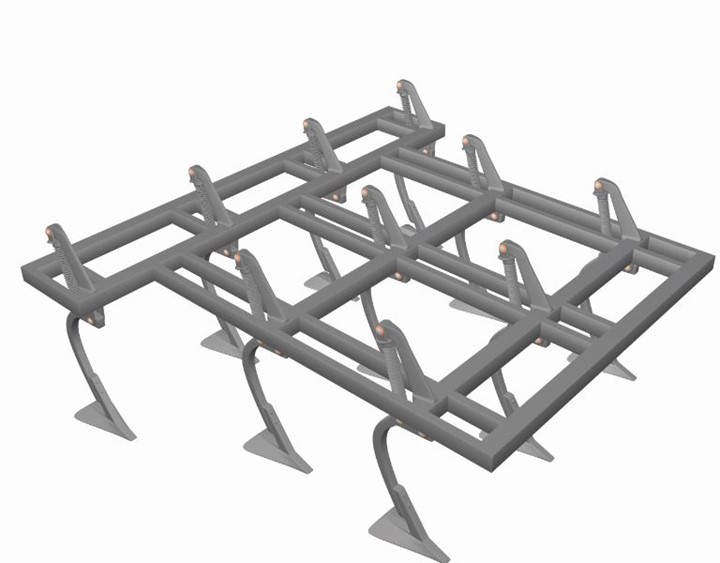

A few years ago, I was consulting with a customer, an engineer at a manufacturer of tillage equipment, on a field cultivator shank pivot. Loads were slightly higher than average, 5000 psi. per bushing. Initial testing used CD AISI 1045 which has an average surface hardness of 20 HRC.

The bushings tested were metal back, Teflon lined and iglide Q. (Q is one of the harder materials we offer) After field testing, it was discovered that both bushings had failed. Upon further inspection, the bushings had actually worn into the shaft. Next, I informed customer that they needed to harden the shaft surface and additional testing garnered much better results.

Let’s dive into some considerations on shaft harness!

Surface Hardness

There are two separate hardness factors that come into consideration when designing a pin, core and surface. Both play a part in your application, but surface hardness is the most important. If the surface hardness is too soft (under 30 HRc), a metallic bearing or even a plain bushing with a high Shore D rating can damage the pin, causing premature bearing failure, and requiring pin replacement.

What is the ideal hardness and how do you achieve it?

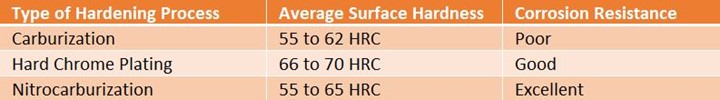

For outdoor applications such as agriculture and construction equipment, where abrasive dirt and contaminants are always present, a surface hardness rating of minimum 50+ HRC is ideal. There are many ways to achieve this, e.g. carburizing (case hardening), hard chrome plating, or nitrocarburization. See table below for comparison.

The biggest drawback of carburizing is the lack of corrosion protection. Hard chrome is a good surface hardening solution and provides good corrosion resistance but requires an extra step in order to provide superior corrosion resistance. However, nitrocarburization provides the best of both, all in the same process. (We will discuss the corrosion resistance component in the third blog)

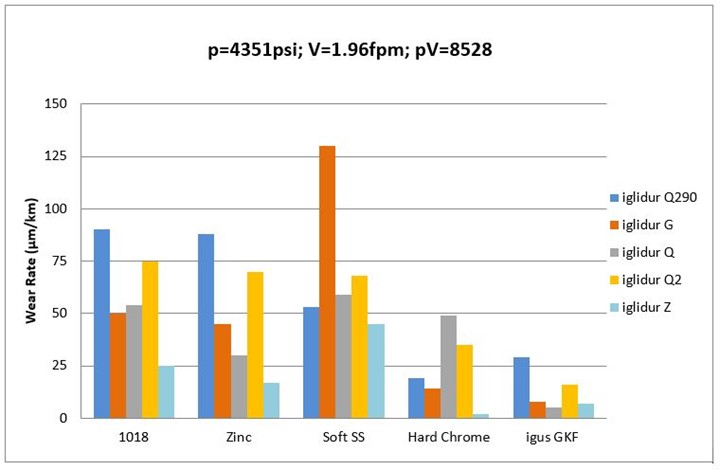

igus® now offers GKF Shafting, which is a version of nitrocarburizing; however, we have optimized the process to provide a superior wear surface for our iglide materials. The table below shows the wear rate of several iglide bushings when mated with various shafting materials and hardness ratings. As you can see with the hard chrome and GKF shafts, the wear rate is significantly lower than the softer alternatives.

For more information on igus® GKF Shafting please visit our website. To speak to our Agriculture and Construction Industry expert here for any questions about our products or specific applications.