What are end effectors and why are they so important in robotics?

By Jared Worth

The end effector (also referred to as end-of-arm tooling) is one of, if not the, most important component in a robotic arm. Without the end effector, a robotic arm is essentially useless. Whether it’s a gripper, welding torch, camera, or something else entirely, end effectors are the component that allows the robotic arm to accomplish its task. With the expansion of robotic arms as an automation solution, it’s more important than ever to understand the ins and outs of end effectors, which is exactly what this blog is going to cover.

What are the different types of end effectors?

End effectors are most commonly split up into three main categories: grippers, process tools, and sensors. Each of these has their own sub-categories (which will be touched upon later), but first it’s important to understand the differences between these first three categories.

Grippers

Robotic arm grippers are by far the most widely used and recognized end effectors due to their versatility across applications and relatively low cost on average compared to other types of end effectors. Grippers are able to grab and manipulate objects, making them the go-to solution for automated pick & place, material handling, and assembly tasks; although, many other applications can also utilize robotic grippers.

Many types of grippers have fingers that can individually grasp and ungrasp objects, similar to those of a human hand. Other more specialized grippers can use needles, suction cups, magnets and more to grab and manipulate objects. Whatever the form of the gripper, applications remain similar.

Process Tools

Perhaps the easiest way to think about process tool end effectors is in relation to grippers. Grippers handle and move objects, while process tools physically change them (think welding or painting). Welding process tools in particular are quite popular, especially in the automotive industry where welding is commonplace; though more niche applications like robotic underwater welding exist as well.

Sensors

Sensors in robotic arms can either be used as a standalone end effector, or as a supporting component for an end effector. When installed as an end effector, sensors are often used for part inspection via cameras, ensuring processes have been completed correctly. Cameras aren’t the only sensors that are able to be used as end effectors — infrared sensors, ultrasonic sensors and laser scanners can also be used (Source: FerRobotics).

When acting in support of an end effector, sensors still find extensive use. In the case of grippers, force sensors can measure pressure in pneumatic and hydraulic systems, and detect leakages or other problems as they occur. Cameras can also act as a vision system for a robot arm, allowing it to accurately determine which components need to be picked up and moved regardless of the position of the component or the arm itself.

3D printed grippers

While many different gripper variants exist, there’s no shortage of custom applications where a more unique gripper is necessary. In cases such as these, 3D printed grippers are an option to consider since 3D printing introduces the possibility to create complex geometries that are not normally possible with injection molding or machining. 3D printed plastic grippers are also lighter and more cost-effective than conventional metal grippers.

Carecos Kosmetik GmbH is a perfect example of a 3D printed gripper success story. They made the switch from machined aluminum grippers to 3D printed grippers from igus due to the exorbitant costs and delivery times of the aluminum grippers. The 3D printed grippers not only were 85% cheaper and delivered 70% faster, but provided stable, long-lasting performance.

End effector compatibility

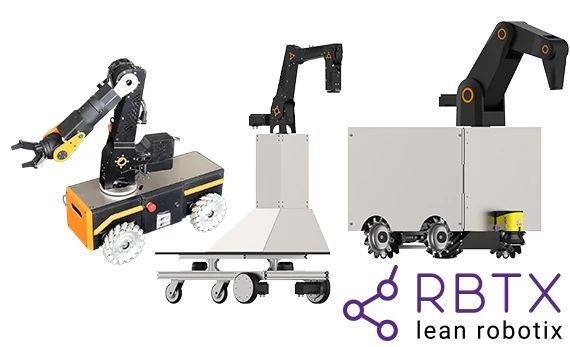

Even if you’ve done your research into robotic end effectors and have determined the best one for your application, there’s still the matter of installing it onto the robotic arm. Questions of compatibility may arise, and can throw a wrench into the entire process if the arm and end effector aren’t compatible. However, a robotics marketplace exists that takes this problem out of the equation entirely: RBTX.

RBTX is a marketplace for fully-assembled robotic solutions, as well as individual components, from a wide range of well-known manufacturers. But, even with all these options in one place, the question still remains: how does any of this help with the compatibility of end effectors? The answer is a built-in robot configurator that only allows compatible components to be combined, eliminating the risk of ordering an end effector that isn’t compatible with the arm itself.

Programming robotic arms & end effectors

So now you’ve put together your robotic arm and end effector, and you’re ready to program the robot. But what if you don’t have the programming knowledge needed to accomplish such a task, or simply don’t have the time for extensive coding? Thankfully, the igus Robot Controller (iRC) software makes it easy to program your robot from scratch even without in-depth programming knowledge. An intuitive user interface and high level of compatibility — gantry robots, delta robots, SCARA robots, and robotic arms of varying axes can all be programmed with iRC — ensure ease of use across numerous applications.

With iRC, grippers can be programmed at the same time as the robotic arm, further simplifying the process. Similar to robotic arms, iRC is compatible with numerous different types of grippers, including those available on the RBTX marketplace.

Conclusion

Robot end effectors can be a complicated topic regardless of how you approach it. However, hopefully after reading this blog you have a better understanding of the topic, and are ready to move forward with your own robotic applications.

To learn more about automation components & solutions from igus, check out our automated manufacturing webpage. If you have any questions about the iRC software, robotic arms & end effectors, or other automation topics, contact our low-cost automation expert.