UV-resistant plastic bearings for the solar industry

By Michael Moalli

As both social and political emphasis on renewable energy sources increases, one of the fastest-growing sources of energy is solar power. With solar power comes large solar fields with dozens, if not hundreds of solar panels each moving with the sun throughout the day. Not only does this movement put frequent stress on mechanical components, but UV-radiation can have a significant impact on these components if they don’t have proper UV resistance. Often, plastic is considered a poor choice in such applications because it’s assumed they’ll become mechanically unsound and fail. However, there are UV-resistant plastic solutions that also completely eliminate the need for relubrication and other routine maintenance. Read on to learn more.

Disadvantages of metal bearings in solar applications

One of the biggest concerns when using metal bearings for applications in the solar industry is maintaining proper lubrication and preventing lubricant from being contaminated by dirt and dust. This is especially difficult since solar panels are constantly exposed to the elements, and are often located in less-than-ideal locations — such as rooftops, deserts, or other remote locations — that make regular maintenance difficult. If lubricant isn’t being adequately dispensed or becomes contaminated with dirt and dust the bearing is almost certainly going to fail, drastically reducing the efficiency of the solar panel and requiring time-consuming and expensive labor to replace the bearing.

UV-resistant plastic components

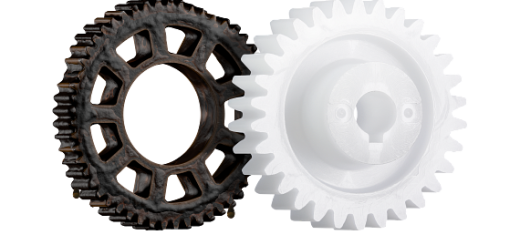

A clear advantage engineered polymer bearings have over metal alternatives is the lack of external lubricants. Instead, solid lubricants are embedded into the bearing material and are evenly dispensed during operation. This eliminates the need for regular relubrication, and prevents dirt or dust from being able to contaminate the lubricant and cause bearing failure. However, this does not address the main concern many have when considering plastic bearings: UV-related failure.

As mentioned before, there’s always been an assumption that plastic components can’t withstand extended exposure to UV radiation, becoming brittle and eventually failing — and for many non-engineered plastics, this is true. However, significant progress has been made in developing engineered plastics that have UV resistance. igus® in particular offers multiple different iglide® bearing materials that can withstand high levels of permanent UV exposure with no adverse effects to performance, including the iglide G and J UV materials. While color may become washed out over time, technical and mechanical properties remain intact.

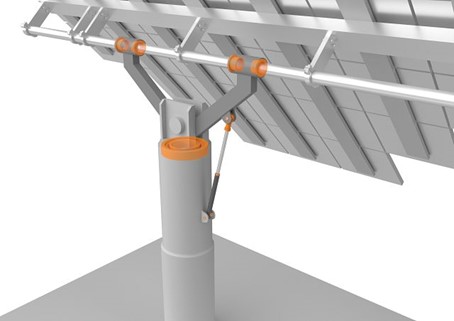

A number of companies already use iglide bearings in their solar applications, including solar tracking systems from RWenergy GmbH and Conergy AG’s photovoltaic plants. These applications both use iglide G, not only for its UV resistance but its dirt & dust resistance and low friction operation. RWenergy’s application even gives customers a “…25-year operational guarantee,” according to their Head of Development Gerhard Dirscherl.

Conclusion

By now, it should be clear that metal bearings are not the only option when it comes to applications in the solar industry, or any other applications where UV exposure is frequent. Engineered plastics can perform just as well, if not better, than metal, and do so at a lower lifetime cost.

For questions about implementing iglide bearings in your own application, contact an igus expert. If you’re ready to make a purchase, visit our online shop!