3D Printing

By Shizu Yamaguchi

What is 3D printing?

3D printing is a process in which materials are repeatedly layered to create a 3D object (McGarry, 2022).

3D printing can involve materials as wide ranging as metals to plastics. Processing techniques vary as well.

One similarity between all processes is that digital data, such as a CAD model, is used to be turned into the given 3D object (Hoffman, 2020).

What is the difference between 3D printing and additive manufacturing?

“Additive manufacturing” and “3D printing” are terms that are oftentimes used interchangeably. Both terms refer to layering materials repetitively to create a 3D object.

However, “additive manufacturing” is more of an umbrella term overall when compared to “3D printing”. Some of the differences are listed below:

Additive Manufacturing

- Often utilized in reference to industrial settings

- Referred to when consisting of large production output or a larger scale output than with 3D printing

3D Printing

- Usually on a smaller scale since it is often used for the prototyping of complex items (McGarry, 2022)

Therefore, “3D printing” is a term that is used mainly when referring to lower-volume processing within non-industrial settings.

What is 3D printing used for?

3D printing is usually used for rapid prototyping.

This process allows product developers to test their designs and to share feedback with lower cost and less time investment. However, there are still situations when 3D printing can be used for larger-scale production. These situations occur when the parts are still relatively low in volume and high in complexity.

For example, aerospace and medical are two industries where 3D printing can be helpful in higher production quantities.

What are some factors to consider when 3D printing?

- Budget

- Mechanical requirements

- Appearance

- Material selection

- Geometry (Tech Zone, 2022)

What are some of the different types of 3D printing?

Stereolithography or SL:

- Original 3D printing process for industrial settings

- High level of detail

- Smooth surface finish

- Tight tolerances

SLS or selective laser sintering:

- Melts nylon-based powders into solid plastic

- Great for functional testing

- Can support hinges and snap fits

- No support structures required, allowing for greater quantities vs other printing methods

- Many SLS parts are used as prototypes that will eventually be injection molded

- More cost effective when printing a single plastic part

FDM or fused deposition modeling, (also known as FFF or fused filament fabrication)

- Common 3D printing technology for desktop machines

- Plastic filament is extruded layer by layer on a platform

- Cost-effective and quick

- Usually produces fairly rough surface finishes

- Not as strong as other methods

DLP or digital light processing:

- Similar to SLA

- Involves curing liquid resin via light

- Often used for rapid prototyping

- Great for low volume production

MJF or multi-jet fusion:

- Functional parts are made from nylon powder

- Fusing agents are applied to the bed of nylon powder and then heat is passed over the layer to fuse the powder into form

- Relatively quick lead time

- Lower production costs

Polyjet:

- A plastic 3D printing process

- Different colors can be applied when using this type of 3D plastic printing

- Best for over molding or silicone rubber design

- Prevents the need to invest in tooling early on in

Direct metal laser sintering or DMLS:

- Great for metal part design

- Works well within medical applications where the metal part needs to mimic an organic part (Tech Zone, 2022)

What materials can be used for 3D printing?

FDM (fused deposition modeling) filament comes in the form of plastic string and is processed by sending the string through a heated tube, melting the plastic along the way—this process is termed “extrusion”. The melted plastic is layered as per the desired design to create a finished component. This type of printing is appropriate for simple prototypes with relatively simple shapes; the end result usually has visible lines where the material was layered. This is also usually the least expensive 3D printing method and is the most accessible for individual or DIY consumers.

SLS (selective laser sintering) powder usually requires an industrial-grade machine to process. Powder is evenly laid down by a component akin to a windshield wiper onto a flat printer bed, and then a laser melts down the shape of the part from the powder, layer by layer. Afterwards, the surface area may appear slightly granular due to the nature of the material. More complex geometries are possible with this type of printing because the parts are surrounded by powder and no additional supports are required while printing. This method of printing can also be quite cost-effective, if done by a printing service.

DLP (digital light processing) resin is a liquid that can be processed using desktop 3D printing machines. UV light is applied to the liquid and selectively hardens, or cures, the resin. The uncured resin then needs to be washed away after the treatment. One thing to keep in mind is that because UV light is the mechanism for creation, the parts are sensitive to prolonged exposure to sunlight or UV rays. This method of 3D printing is by far the most accurate for the most complex geometries. Also, these parts can often be applied in production due to their durability and accuracy.

At igus, we offer a range of iglide® 3D printing materials that work well for applications that require high wear-resistance or other specifications, such as food contact, chemical resistance against alcohols and oils, black and white colours, high mechanical strength, and multimaterial printing.

Why consider wear-resistant 3D printing materials?

- The wear can be significantly lower than a regular plastic part.

- The part would be dry-running and maintenance-free.

- The part would stay clean and hygienic due to its grease-free nature.

- The part could safely be near food and therefore would work well in food and beverage industry settings.

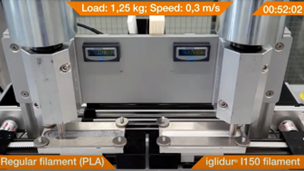

Wear resistance test:

The below images refer to a comparison test between PLA filament and wear-resistant iglide® I150 filament; You can see that the white I150 material after over an hour of wear has only very slightly been affected, in sharp contrast to the PLA material, which has worn down considerably in the same amount of time.

This test allows us to see that wear-resistant filament produces durable products that show little sign of damage compared to those made of regular filament under the same environmental conditions.

What are some options for FDM 3D printers?

Low-cost 3D printer with open frame (e.g.: Prusa i3, Creality, etc.), usually less than $1,000

3D printer with enclosed and possibly heated enclosure (e.g.: Ultimaker S5 Pro, Zortrax, Raise3D)

High-temperature 3D printer with isolated and heated enclosure (e.g.: Intamsys, Gewo3D, 3Dgence)

How do you select between different 3D printing processes?

First, you need to understand the strengths and weaknesses of each process so that you can compare these different strengths against your product development requirements to determine which method is ideal (Tech Zone, 2022).

FDM vs. SLS

SLS advantages:

- Fast, low cost for higher quantities

- Part quality is high

- Complexity does not incur extra costs

- Customer can quickly receive economical and functional parts

FDM advantages:

- Cost-effective technology, with pricing at a few thousand Euros; Flexible and available in a variety of materials

- Up to four materials can be processed at once

- Fast in-house prototyping and production from various materials (Igus, 2020)

How can you 3D print your own parts? What are the options?

One way to get your 3D object printed would be to purchase your own 3D printer. Another would be to use a 3D printing service.

Here are a few reasons why you might want to use a 3D printing service instead of purchasing your own setup:

- It can get expensive to buy your own 3D printer. Although pricing can start at USD200 (for a FDM printer), you should be aware that a considerable amount of fine tuning will likely be required for a 3D printer that is this inexpensive.

- You only need to print a handful of components that are required for one project. If you have a longer term requirement for 3D printing objects, you may want to consider purchasing a 3D printer.

- You don’t understand CAD modeling well.

- If you don’t have a properly ventilated space, it can be dangerous to try 3D printing on your own.

- 3D printers break down fairly often and there are not many services that will come by to fix your device. So, unless you are willing to do some fixing, you will likely be better off using a 3D printing service.

Read more about the downsides to owning your own 3D printer here (Stevenson, 2020).

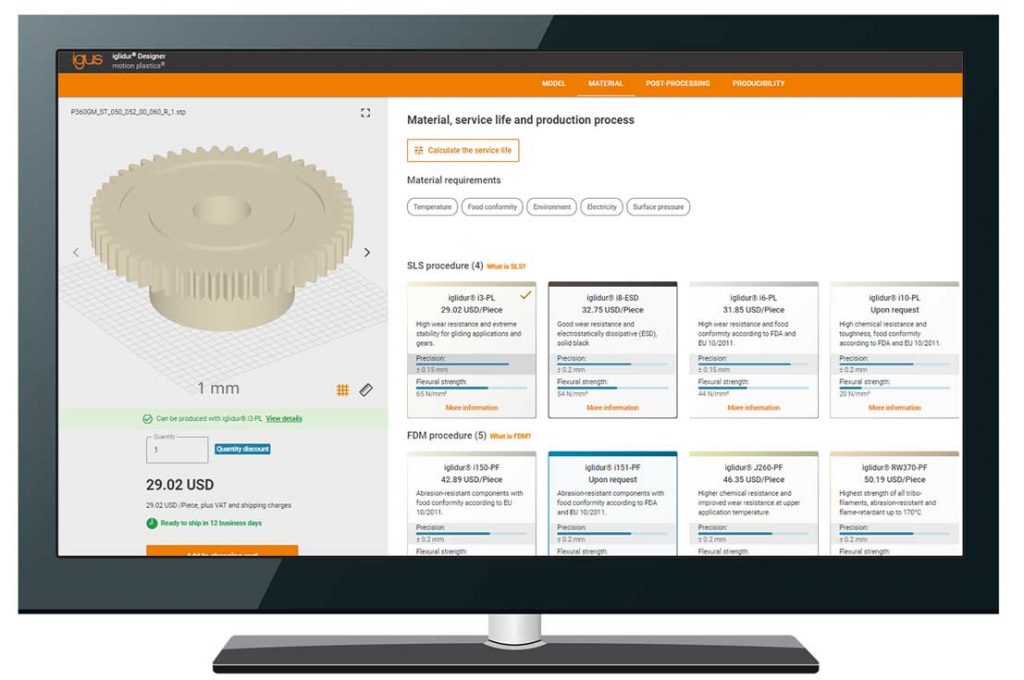

If you decide to go forward with a 3D printing service, you should consider igus, which is based out of Rhode Island, USA and offers low-cost international shipping to Canada.

Simply upload your CAD file to immediately see what your part looks like in a 3D visualizer, along with the pricing for the quantity of your choice, in the material of your choice. Pricing is competitive and no minimum is required. Additionally, there is no login or sign up required to use the tool.

Popular 3D printed products include gears, bushings, rollers and lead screw nuts. There are very few limitations on what type of design can be printed.

One standout feature of our 3D printed materials is that they are designed for applications where there is motion and friction. Our powders and filaments have been proven to last up to 50 times longer than standard 3D printing materials within moving applications since they are each rigorously tested in our 41,000 square foot test lab located at our international headquarters in Cologne, Germany.

All of our 3D parts are self-lubricating and maintenance-free, with options for high loads, contact with food, media resistance and high temperatures.

We offer several different SLS print materials. Here is a quick guide:

i3 = Extremely wear resistant, for gears, burn and fog testing, automotive interiors

i6 = White, great with worm gears, abrasion resistance, robust, FDA approved

i8 = Black, offers ESD protection

Other material options include FDM filament, DLP resin and our print2mold production process.

When you are ready to purchase, you can add your desired 3D printed items to your shopping cart with just one click and then go directly to the checkout to place your order. Your 3D printed parts will then ship in as early as 2-3 business days.

Visit our 3D Printing Service page.

References

Hoffman, T. (2020, July 1). 3D Printing: What You Need to Know. PC Mag. https://www.pcmag.com/news/3d-printing-what-you-need-to-know

Igus. (2020, December 8). Which igus 3D printing material is best for my application/printer? [Video]. YouTube. https://www.youtube.com/watch?v=pvC3or13IxA

McGarry, S. (2022, July 20). What are the Differences Between Additive Manufacturing and 3D Printing?. Autodesk. https://www.autodesk.com/products/fusion-360/blog/what-are-the-differences-between-additive-manufacturing-and-3d-printing/

Stevenson, K. (2020, September 8). 8 Reasons Why You Should Not Buy A Home 3D Printer. Fabbaloo. https://www.fabbaloo.com/2020/09/8-reasons-why-you-should-not-buy-a-home-3d-printer

Tech Zone. (2022, August 21). Types of 3D Printing Technology [Video]. YouTube. https://www.youtube.com/watch?v=0FrcgPd-7G8