Axial Play vs Radial Play: What’s the difference?

By Jared Worth

As an engineer, understanding the differences and implications of axial play and radial play is crucial when designing and manufacturing precision mechanical systems. These two terms refer to the amount of movement or “play” exhibited by a component along different axes, impacting the performance and reliability of various machines and mechanisms. In this blog, we will delve into the concepts of axial play and radial play, their significance, and how they influence engineering decisions.

Definition and Differentiation

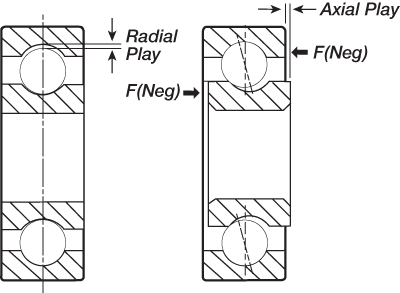

Axial play and radial play are mechanical terms used to describe the free movement of a component along different directions. Axial play refers to the movement of a component along its longitudinal axis (parallel to the axis of rotation), while radial play pertains to the movement perpendicular to the axis of rotation. The magnitude of this play can significantly affect the functionality and precision of mechanical systems.

Understanding Axial Play

Axial play, also known as endplay or axial clearance, is prevalent in components such as bearings, shafts, and gears. It represents the amount of permitted axial movement of a component within its housing. Excessive axial play can lead to misalignment, vibration, and even catastrophic failure. On the other hand, insufficient axial play might cause binding and premature wear.

In applications where axial forces or thrust loads are present, proper consideration of axial play is crucial to ensure stable and reliable operation. Engineers must carefully calculate and specify the allowable axial play based on the application’s requirements and the characteristics of the components involved.

Unraveling Radial Play

Radial play, also known as radial clearance, refers to the movement of a component perpendicular to the axis of rotation. This play is critical in applications involving rotating elements such as ball bearings and pulleys. The radial play determines the space between the rotating component and its housing, affecting factors like rotational smoothness and heat dissipation.

Selecting the appropriate radial play is a balancing act. Too much radial play can cause excessive vibration and reduce the system’s precision, leading to decreased efficiency and accelerated wear. Conversely, insufficient radial play may lead to frictional losses, elevated temperatures, and potential system failure.

Factors Influencing Play

Several factors can influence the axial and radial play in mechanical systems. These include temperature variations, material properties, manufacturing tolerances, and the operational environment. Engineers must carefully consider these factors during the design phase to optimize the system’s performance and longevity.

Minimizing Play for Enhanced Performance

Reducing axial and radial play can lead to improved system performance. By employing high-precision components, carefully controlling manufacturing processes, and implementing adequate preloading techniques, engineers can minimize play and enhance the system’s accuracy and efficiency.

Conclusion

In conclusion, the distinctions between axial play and radial play play a pivotal role in engineering applications, particularly in precision mechanical systems. Understanding the significance of these concepts empowers engineers to make informed design decisions, optimize system performance, and ensure long-lasting reliability.

Balancing axial and radial play is a delicate task, but one that ultimately determines the success of many mechanical systems. By acknowledging the interplay between these factors and leveraging advanced technologies, engineers can unlock new realms of innovation and create cutting-edge machines for the future.

For questions about your own application, fill out an expert contact form or call igus directly at 1-800-965-2496.