Get ready for the future with the igus Automotive FastLine Service

The development time for new cars has continued to decrease in recent years. One reason for this is the consumer, who is used to receiving a new product innovation every year, especially from the electronics industry. But the primary change in the automotive market comes from rising competitors such as Tesla, BYD, Geely, and others.

Volkswagen’s Head of Development, Thomas Ulbrich, says that “Vehicle projects […] should be created in 40 months instead of the 54 months that used to be normal.” The Handelsblatt reports that Mercedes also wants to reduce the development time for main vehicle types such as the E-Class or GLC from 58 to 40 months.

This increased time pressure is passed on to automotive suppliers, so time for prototype development and construction is also reduced. C-parts such as polymer plain bearings are especially likely to be overlooked under these conditions. But it can take several weeks to get injection-moulded plastic parts ready for series production. The bottleneck in the process is often the tool shop, which produces an individual tool in several loops including quality control, corrections, and samples.

igus Canada is now offering its FastLine Service, a solution for just this problem. Optimized process flows and our own CNC and injection moulding machines in our headquarters in Rhode Island dedicated to FastLine enable igus Canada to greatly reduce the throughput time for special plain bearings according to automotive quality standards.

The customer can receive the first parts in as little as seven days. After the first sampling, tool corrections are made as necessary and PPAP documentation is prepared. This service is available for sleeve bearings with or without a flange and for thrust washers. Other shapes and special geometries are also to be manufacturable with the igus FastLine service in the future.

The unique service, originally based out of Germany, was also recognized by RWTH Aachen and the Fraunhofer Institute, receiving the “Excellence in Production” award.

Excellence in Production – 2022 winner

Do you have a project for which you need individual bearing samples suitable for series production?

Use the iglide® Plain Bearing Designer to design your bearings directly

The igus FastLine service helps you to remain flexible in an increasingly dynamic automotive market and to react quickly.

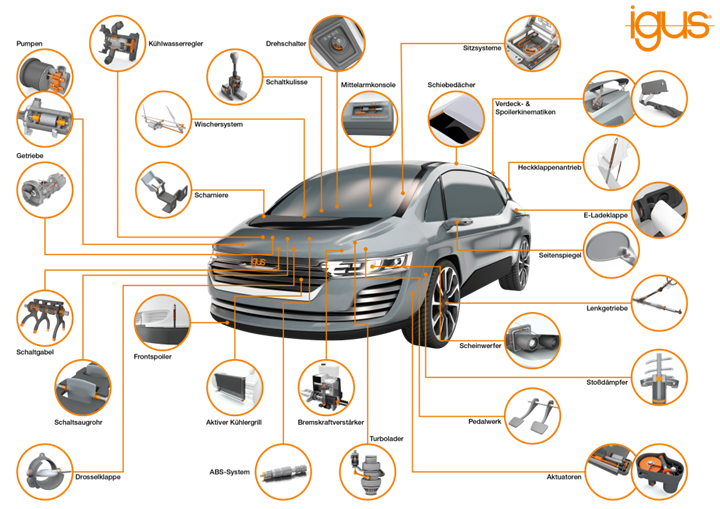

igus plain bearings are widely used in vehicle construction and offer a number of advantages over conventional metallic solutions:

- Noise reduction

- Cost reduction

- Design freedom/flexible installation

- Weight reduction

- Corrosion-resistance

- Lubrication-free

- And more

We would be happy to send you a free automotive sample box in advance. You can order it here:

https://content.communication.igus.net/de-de/iglidur-automotive-box

More information: automotive industry, plastic bearings for engine compartment applications and the automotive interior and exterior