What is a clevis?

By Jared Worth

In the vast world of mechanical components, clevises stand out as versatile and essential elements in various applications. These simple yet effective devices play a crucial role in connecting different components, providing flexibility, and facilitating movement in diverse mechanical systems. This blog will delve into the intricacies of clevises, exploring what they are, how they are used, and the different types available.

What is a clevis?

A clevis is a type of fastener that most often consists of a U-shaped piece with holes at each end and a clevis pin that passes through the holes. The design of a clevis allows for articulation or movement at the joint, making it an ideal component for applications where flexibility and adaptability are required. The main components of a clevis are the clevis itself, the clevis pin, and a tang or clevis mount. The clevis pin is inserted through the holes of the clevis, and sometimes held in place with a split pin or a circlip. The clevis pin holds the tang in place between the “prongs” of the clevis.

How clevises are used

Clevises are used in a variety of different applications. Below are some of the most common.

Linkage Systems: Clevises are commonly used in linkage systems where they connect rods, levers, or other components. This linkage allows for the transmission of force or movement between different parts of a machine.

Control Systems: In control systems, such as those found in aircraft or industrial machinery, clevises are employed to create adjustable connections. This enables precise control over the movement of control surfaces or other critical components.

Tie Rod Assemblies: Clevises are integral in tie rod assemblies, providing a secure and adjustable connection between the tie rod and other components. This is crucial in applications where tension or compression forces need to be managed.

Automotive Applications: Clevises find use in various automotive applications, including brake systems and suspension components. They contribute to the smooth and controlled movement of different parts within these systems.

Read more: Plastic bearings & clevis joints for pipe organs

igubal® clevises were the ideal choice for this pipe organ application, damping vibrations and eliminating routine maintenance

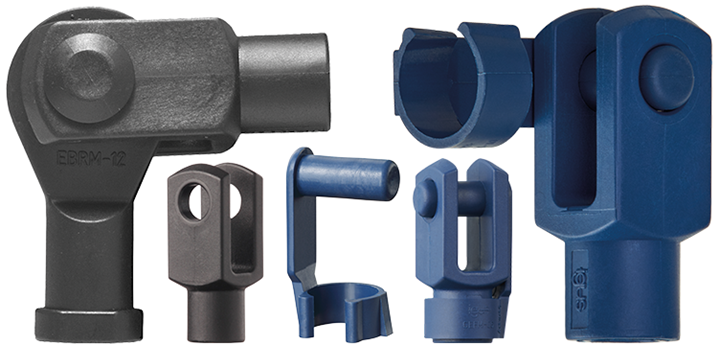

Clevis types

Not all clevises are the same. Different types of clevis fasteners are used depending upon application requirements. The most common types are shackles, brackets, clevis hangers and clevis rod ends.

Shackles: The “standard” clevis, clevis shackles are what most people will first think of when clevises are discussed. They use the classic U-shaped design, along with a tang and clevis pin.

Brackets: Clevis brackets are similar to shackles in design, with the biggest difference being its rectangular shape rather than being U-shaped. The rectangular hook has holes that can be used for bolts or screws. Brackets are most commonly used within cars or aircraft.

Clevis hangers: Clevis hangers consist of two clevises: a standard U-shaped clevis and a V-shaped clevis. These two clevises are connected with a clevis pin or other similar fastener. They’re most often used to suspend pipes from a ceiling or other elevated support.

Clevis rod ends: Clevis rod ends (also called yoke ends) use the same U-shaped hook found in many other types of clevis. The key difference between clevis rod ends and other clevis fasteners is the hole at the base of clevis rod ends. This hole is often threaded in machined parts to provide additional stability.

Plastic clevises versus metal

In many applications, you’ll find metal clevises being used. This is both because of the prevalence of metal options, and assumptions about metal compared to alternatives like plastic. However, tribologically optimized plastic clevises — like those from igus® — offer a number of advantages over metal alternatives, like maintenance-free operation, resistance to corrosion, vibration-damping properties, and weight reduction of about 80%.

Maintenance-free operation: igus’ plastic clevises use tribologically optimized polymers (triboplastics) with embedded solid lubricants all throughout the material. This eliminates the need for any sort of external lubrication, and therefore routine maintenance. The lack of grease or other external lubricants also helps resist dirt & dust.

Corrosion-resistance: The plastics used in igus’ components are resistant to corrosion, making them ideal in applications with frequent exposure to moisture or chemicals. These triboplastics can also resist weak acids and alkalis and do not suffer any structural deterioration when exposed to them.

Weight reduction: It’s no surprise plastic weighs less than metal. This difference is often as much as 80% in the case of igus’ components. This is particularly important in automotive or aircraft applications where weight is one of the most important considerations for engineers.

Vibration-damping: Triboplastic clevises are designed to damp noise and vibrations common in the heavy-duty applications most clevises are used within. This can help extend the total service life of the component, as well as improve overall performance.

Read more: 6 lesser known benefits of engineered plastic bearings

Conclusion

Clevises, with their simple yet effective design, play a vital role in connecting components and facilitating movement in a wide range of applications. Whether in machinery, automotive systems, or aerospace, the versatility of clevises makes them indispensable. By understanding the types of clevises available and their applications, engineers and designers can make informed decisions to optimize the performance and reliability of their mechanical systems.