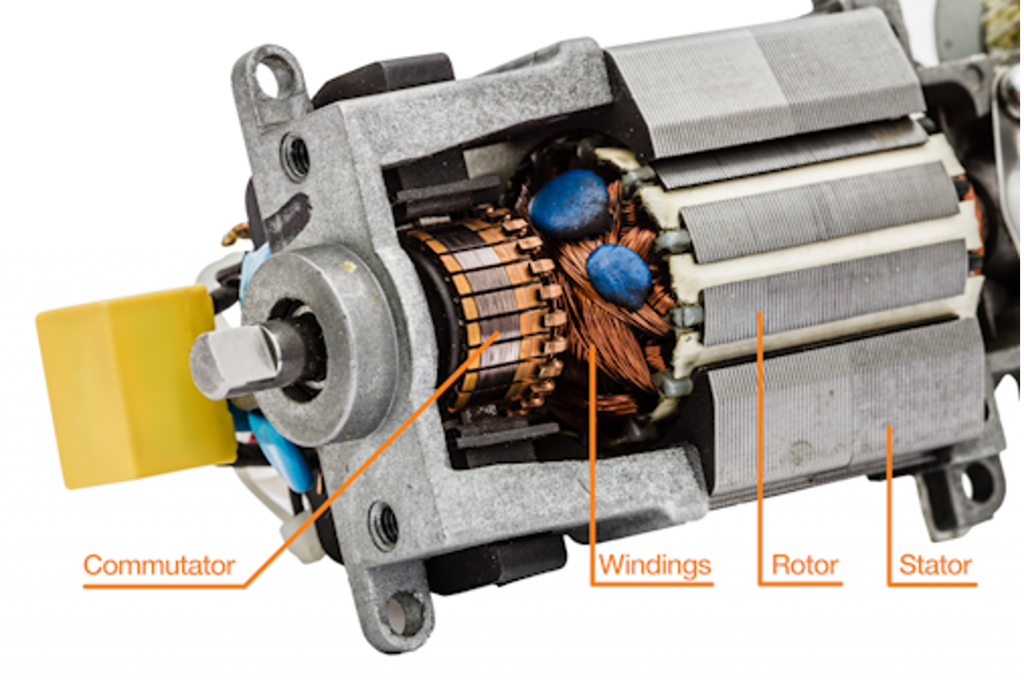

Key parts of an electric motor

By Jared Worth

Electric motors are the leading source of electric energy usage worldwide, accounting for roughly 45% of global electric energy consumption. They power everything from household appliances like blenders and fans to industrial machinery and electric vehicles. While they may seem complex, their operation is based on a few key components working together to convert electrical energy into mechanical motion. The core parts that make this happen are the stator, the rotor, and in many cases, a commutator.

This blog will break down what each of these components does and how they interact to make an electric motor function.

Related: Choosing the right motor for your application

What is a stator?

The stator is the stationary part of an electric motor. It can be thought of as the outer casing or frame that houses the primary electrical components. It’s typically made from laminated steel to help concentrate the magnetic field and is lined with coils of insulated wire called windings. The windings are where electrical energy is supplied to the motor.

When an alternating current (AC) is sent through the windings, a powerful magnetic field is created. The design of the stator’s windings and the way the current flows through them causes the magnetic field to rotate — forming the core principle of motor operation.

The spinning magnetic field of the stator interacts with the rotor, which is the rotating part of the motor housed inside the stator — except in the case of outrunner motors, where the rotor is located outside of the stator. The interaction of these two components is what generates the torque that makes the motor spin.

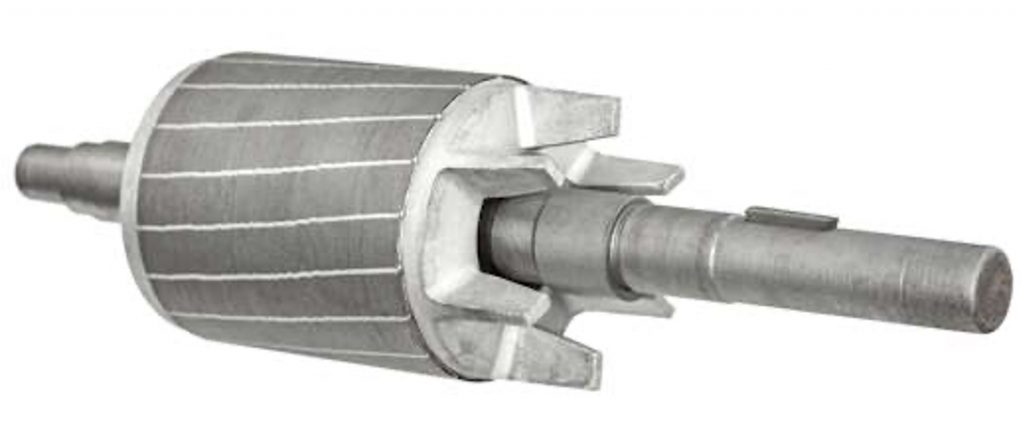

What is a rotor?

The rotor is the rotating component inside an electric motor. The rotor is typically made from a laminated steel core to enhance its magnetic properties and is mounted on a shaft that extends outside the motor’s housing. This shaft is what connects to a load to deliver the motor’s power.

A rotor’s function is based on the fundamental principle in magnetism that opposite poles (positive/negative) will attract, and like poles (positive/positive or negative/negative) will repel. The rotor’s own magnetic field interacts with the rotating magnetic field of the stator to facilitate the motor’s motion.

As the stator’s magnetic field rotates, it exerts a force on the rotor, causing it to try and “catch up” to the spinning magnetic field. This constant pushing and pulling force on the rotor is what creates the continuous rotational motion that drives the machine the rotor is connected to.

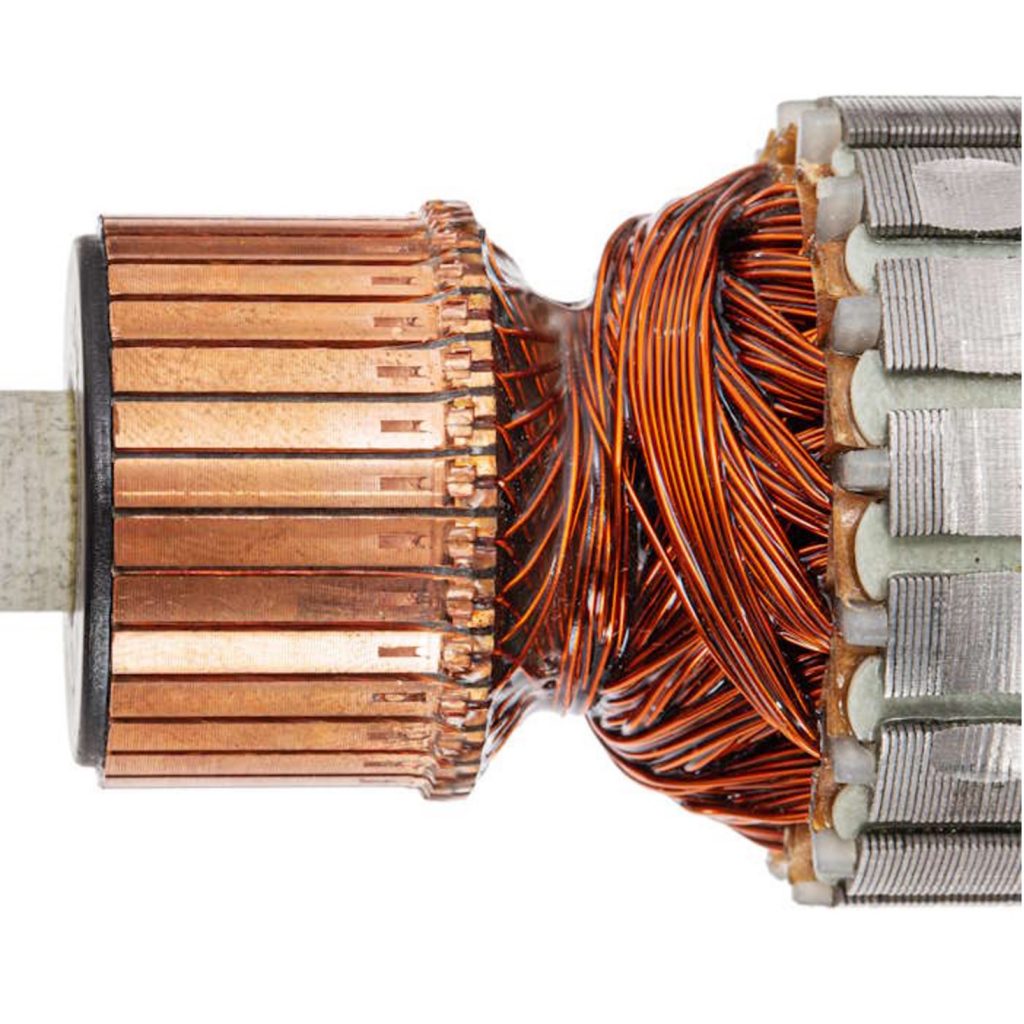

What is a commutator?

A commutator is an essential component in most direct current (DC) motors. It’s an electrical switch made of copper segments arranged in a ring. Two brushes — stationary electrical contacts often made of carbon — press against the commutator to supply power to the motor’s coils.

The commutator is used to periodically alternate the direction of the electric current flowing into the rotor. If the current always flowed in the same direction, the rotor would make a single half-turn and then stop. A commutator changes the direction of the current at the precise moment needed to keep the rotor moving in a single, continuous direction.

Brushless DC (BLDC) motors do not use commutators, instead relying on an electronic controller that uses semiconductor switches (transistors) to reverse the direction of electric current as needed. Brushes require sliding contact to function, so BLDC motors generate less friction and improve service life compared to brushed DC motors by eliminating them. This reduced friction translates to about a 10% difference in overall efficiency.

White Paper: 11 tips for selecting the right motor control unit

Conclusion

Understanding the function of the stator, rotor, and commutator is key to comprehending how electric motors convert electricity into motion. The stator’s stationary magnetic field interacts with the rotor’s own magnetic field to generate the torque that makes the motor spin. This fundamental interaction of magnetic fields is what drives the continuous rotational motion of a motor. For brushless motors, commutators are necessary to change the direction of current and keep the rotor moving in a single, consistent direction.