iglide® bearings for automotive thermal management systems

By Jared Worth

Proper thermal management is always a concern for automotive manufacturers. Without it, significant damage or even complete failure of essential systems like the engine would occur. But as components in vehicles get smaller, electronics become more prevalent throughout the entire vehicle, and more automakers shift towards electric vehicles, thermal management becomes a greater challenge. Having reliable components in thermal management systems has thus become essential, and this is where igus® components come in. This blog will explore some of the potential applications of these components in thermal management systems and explain the benefits of making the switch.

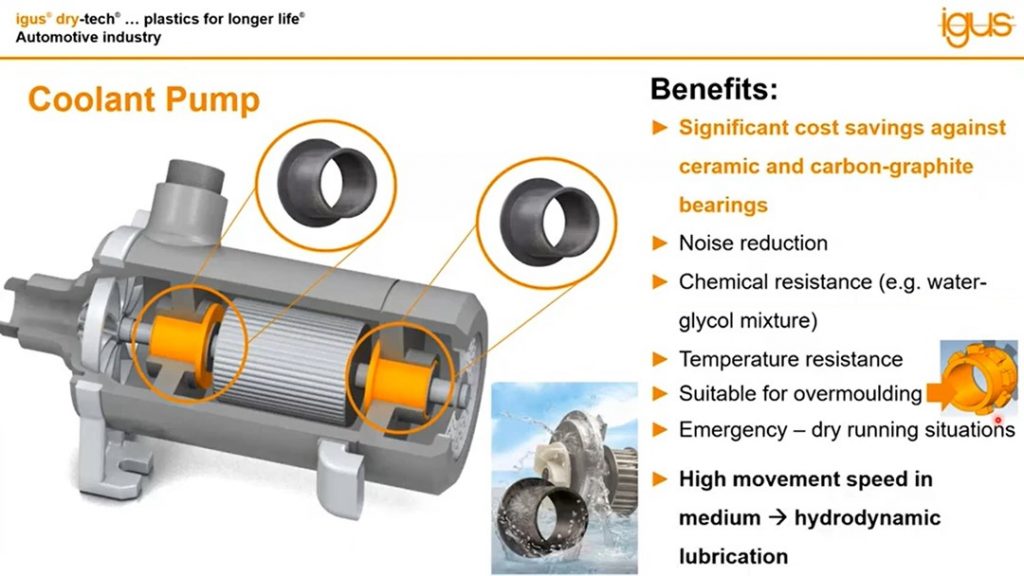

Engine Radiator

The radiator in a vehicle’s engine is easily the most important component when it comes to automotive thermal management. If the engine overheats, wear is increased and the possibility of total failure is introduced — and without a working engine, a vehicle isn’t of much use. Radiator cooling pumps often utilize ceramic or carbon graphite bearings, but iglide® plain bearings are a significantly lower cost option, with a host of other benefits as well. These include quiet operation, resistance to chemicals (such as the water-glycol mixture commonly used as engine coolant), temperature resistance, and dry-running capability in emergency situations where the radiator may be operating without coolant.

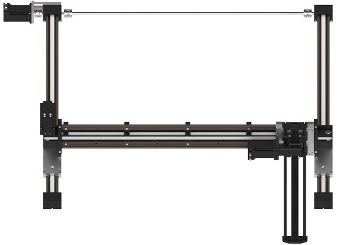

Active Grille Shutter

Active grille shutters control the air flow into a vehicle as a means of thermal management. They cover the air inlets found on the front of nearly any vehicle, and open & close depending on what’s needed at a given moment. In extremely hot conditions, the shutters can open to improve air flow throughout the cabin, cooling it down. In cold weather, the shutters can close to help heat the cabin up and defrost the car’s windshield more quickly (Source: Valeo).

Since active grille shutters are part of the exterior of a vehicle, corrosion-resistance is a necessity as contact with water can’t be avoided. iglide® plain bearings fit this requirement, while at the same time providing resistance against dirt & dust — another essential feature for an exterior automotive component — along with many of the previously mentioned benefits such as cost reduction relative to comparable bearings and quiet operation.

Actuators

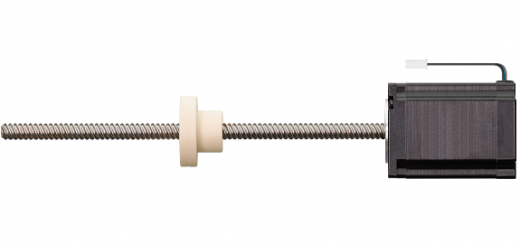

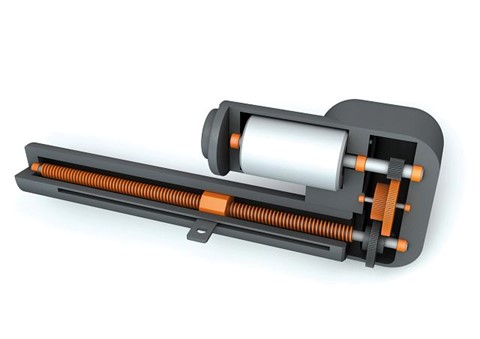

Actuators are used all throughout a vehicle, including the previously mentioned radiator coolant pumps and active front grille shutters. Like with those other applications, iglide® plain bearings are a cost-effective solution that provides quiet, dry-running operation. However, actuators can also make use of iglide® gears as well as dryspin® lead screws and lead screw nuts. The gears and lead screw nuts use the same materials as iglide® plain bearings, and thus offer the same advantages. The dryspin® lead screws are corrosion-resistant and provide a higher level of efficiency relative to traditional trapezoidal lead screws. Noise and vibration is also reduced with dryspin, as the lead screw nuts are made of dry-running polymers with embedded lubricants. This ensures even lubrication across the entire lead screw, and eliminates metal on metal contact that would typically cause squeaking and excessive vibration.

To learn more about igus components used in the automotive industry, visit our automotive webpage. You can also watch our webinar for more specific information about our components in automotive thermal management. Finally, for specific questions about a component or application, email us!