Why Do We Offer So Many Online Tools? I Learned from Experience

By Matt Mowry

Many customers ask, “Why do you guys offer so many online tools? Should we be using them more often?” My immediate response is always “absolutely”. And, I can confidently vouch for this based upon personal experience.

I recall working on a project many years ago as a new outside technical salesperson for igus®—I think that I had maybe eight months in. Following my MapQuest printouts from one manufacturing site to the next, I parked at the customer’s facilities, and walked in with my catalogs, sample case, and my twenty-something year-old enthusiasm. I was not only new to igus®, and bearings in general, but also new to sales and the entire world of manufacturing. Since I was so green, I would simply open my sample-case on the conference table, hoping that the customer would see something they thought was interesting for an application and jump on it. This was back in 2000, when we did not have nearly as many of the online calculation tools at our disposal as we do currently.

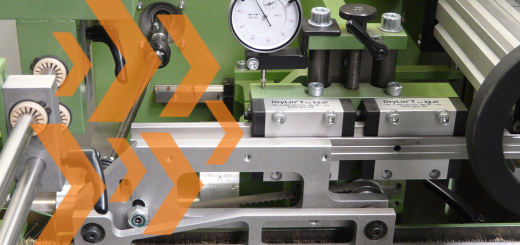

Well, this one engineer, who was probably only a bit older than me, did find an interesting part within my sample case and instantly became very excited. The part that had caught his eye was drylin®N, which is a really low-profile linear guide designed to fit into small spaces. He had been designing a new application for a machine and was having a difficult time finding a recirculating ball bearing that was small enough to meet his space requirements at a reasonable cost. After gathering his manager, along with a couple of other engineers, they began to examine and discuss the part while I scribbled down some of the application details and taught them about the “2:1 Rule” for sliding plastic bearings. With everyone’s unanimous approval, we then looked at the catalog page for the part that they wanted so we could quickly check the loads and settle on some part numbers. Words cannot describe how excited I was—they were going to need 4,000 systems per year, making it one of my first massive projects! When I returned to the office, I sent him enough samples to start prototyping with, and called my boss with the great news.

Learning a Tough Lesson About the Importance of Tools

About three to four weeks later, a colleague from our headquarters in Cologne, Germany arrived at the US facility in Rhode Island, planning to stay for a few months. Upon learning that he would be accompanying the outside sales people during certain technical visits, I jumped at the opportunity, and requested that he join me on a visit with my new big-project customer in North Carolina. The customer happily-agreed to have my colleague and I for a follow up visit to see how the prototype was working for them.

The morning of the big visit, I stuffed my 1998 Toyota Tacoma (not the most ideal vehicle for traveling with two people) full of catalogs, samples, and suitcases, and headed off to pick up my German colleague at the airport. Needless to say, I was a bit intimidated—he had been at igus® for over ten years and seemed to know everything about bearings and the entire industrial world. During our two-hour drive, I briefed him about the application and how excited they were. He then calmly asked, “did you run this in the new excel-based calculation tool?” My heart instantly sank as I fixated on the white lines running down the interstate.

“No… I forgot we really even had that, but I did talk to him about the 2:1 rule and he said there were no overhung loads and the drive force was right where it needs to be.” I felt foolish that I hadn’t used our new tool yet, but was confident from my weeks of experience that everything would be ok.

After arriving at the company, we walked into the lobby where the receptionist called my contact. We both stood there in our suits, staring at the trade journals on the coffee table and observing the awards and patents that hung on the wall. Once my contact and some additional engineers greeted, we shook hands and made small talk.

“So how is the machine coming? How did our parts work out?”, I confidently asked.

“Well… That’s why we are glad you guys came by today. The parts did not work—they wore out after only a few hundred cycles. Maybe you can help us find another solution that works?”

#EpicFail

Instantly, I realized that I had never asked how fast the linear parts would be moving, or inquired into the full details regarding how the parts were going to exactly be used. Although we had checked the static load of the parts—500N (112lbf) x 4 bearings—I had failed to ask, in detail, about the speed and cycles. I assumed that the customers would know about PV value and sliding bearings—but then, why should they? I was supposed to be the expert. Now that I clearly recognized that the part needed to continuously move 500N at three-meters-per second without any dwell time, I felt like the biggest moron on earth.

With the appropriate excel tool finally being used, we were able to find a substitute solution. However, they needed to have a solution ready in two days, and we unfortunately did not have anything standardized and immediately on-hand at the time that could meet the size requirements. In the end, I ultimately lost the project. Despite feeling horrible that my colleague had flown all the way from Rhode Island to North Carolina to visit me and I had handed him a rotten egg, he was a good sport about everything as we discussed the situation out in the parking lot in front of the Tacoma. He then explained to me how important it was to use the tools our lab had created since we offer a newer technology that although has many potential benefits for our customers, still needs to be designed into the application correctly. This way, we are able to provide our customers with the confidence that our sliding plastic bearings will work before they test them. After we piled back into the truck, he jokingly complained about how uncomfortable he was in the over packed Tacoma as we bounced down the byways, making other sales visits over the course of two days—none of them nearly as overwhelming and unsuccessful as this one though, thankfully.

Online Tools Prevent Us from Becoming Tools

Ok, I admit it, I had dropped the ball and been a total idiot, but trust me, I learned the hard way when I was young, and since then, an application solution does not go out without me running the calculations through our tools first. Even after twenty years at igus®, and fifteen years of managing the product line, I still run the simplest applications through the tools we have created. The best part is that all of these tools live online, for anyone to use—they’re even free! Well, the free part you probably were expecting. However, I really encourage you to check out our drylin® linear motion tools before you order your linear parts, whether for testing or installation, so that you receive the most beneficial solution possible. To help make things a bit easier, I have made a short walk-through tutorial for you to watch if you would like a quick explanation of how to use it:

By the way, the Tacoma still runs—250,000 miles later. Before I purchased it, I did heavy research into the factory testing; I wanted a truck that lasted very long time—just as you should with your linear bearings.