5 IIoT Solutions for Manufacturing

By Jared Worth

If you’re part of the manufacturing industry, you’ve likely witnessed the integration of automation into daily operations. However, the lesser-known Industrial Internet of Things (IIoT) can provide effective solutions for common manufacturing challenges, potentially leading to up to 30% savings in maintenance costs. In this blog post, we will explore these challenges and some IoT solutions for manufacturing to solve them.

What is the IIoT?

Before discussing the ways in which Industrial IoT(IIoT) can be implemented in the manufacturing industry to develop smart factories, it’s important to understand what exactly it is. Industrial IoT is a subset of IoT, but they both function in essentially the same manner: They connect objects over a shared network via technology – most often sensors and software working in tandem – to allow for the transmission of data between said objects as well as to the cloud. From there the data can be analyzed and applied by the user, or in certain cases by AI to solve problems and optimize processes.

Predictive Maintenance: Improve Efficiency & Cut Costs

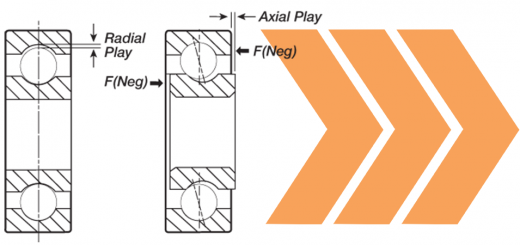

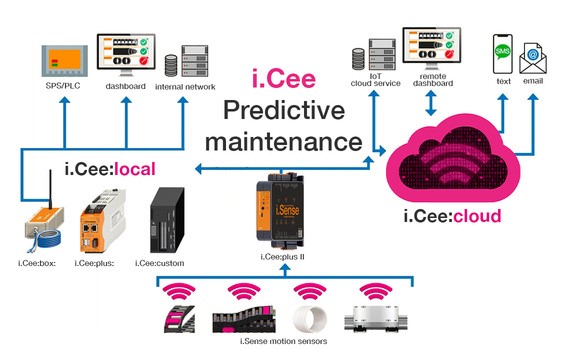

Predictive maintenance utilizes condition monitoring through sensors to determine when a machine requires maintenance. With 24/7 access provided by IIoT, minor changes in data can be detected and addressed immediately, preventing unexpected downtime, reducing costs, and improving efficiency. At igus®, we offer our predictive maintenance system, i.Cee, which leverages extensive data collected from our 3,800m2 testing facility for accurate service life predictions, considering specific application conditions.

At igus®, we offer our own predictive maintenance system, called i.Cee. i.Cee makes use of the extensive data collected from our 3,800m² testing facility to make accurate service life predictions. These predictions also take into account how the equipment is being used in any particular application to ensure further accuracy.

Enhancing Worker Safety with IIoT Technology

IIoT not only allows for monitoring machines and products but also enhances employee health and safety. Radio frequency identification (RFID) technology enables remote identification and location tracking of individual workers, enabling alerts for hazards like chemicals or gases. Additionally, workers can use wearable tech to monitor vital signs, ensuring timely reporting of any adverse changes. RFID and vital sign monitoring together enable swift responses to health emergencies.

Streamlining Inventory Management with RFID tagging

In large, expansive warehouses, lost or misplaced products are an unfortunate reality. Human error simply can’t be avoided, but with IIoT and RFID technology, it can easily be corrected. As long as inventory is outfitted with an RFID tag, it can be constantly and accurately monitored. If a product is misplaced, lost or erroneously sent out, a notification is sent to the user to alert them of the mistake.

Automation Made Easy: Leveraging IIoT for Efficiency

IIoT empowers the optimization of new processes and the expansion of automation in manufacturing. Automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) perform tasks like item transportation and safety checks. AI and machine learning enhance the capabilities of these vehicles, allowing them to react to obstacles independently, reducing or even eliminating the need for human oversight.

More traditional robots, such as robotic arms and cobots, can also benefit from IIoT. The consolidation of data stemming from IIoT gives manufacturers the capability to make adjustments on the fly to improve efficiency or create solutions to entirely new problems. Some applications that implement machine learning and AI even see robots doing this on their own. Ultimately this can lead to increased efficiency and service life of the robots, saving money on costly replacements or repairs.

Smart Metering for Resource Optimization

While smart meters are commonly used in city infrastructure, they can also be applied to manufacturing. These meters, connected via IoT, allow for remote monitoring of resource consumption. By eliminating the need for in-person inspections, smart meters reduce diagnosis time and prevent issues or outages. Data from smart meters can be analyzed to optimize resource usage, reduce waste, and cut unnecessary expenditure. Blockchain technology can further enhance and optimize smart meter systems.

Conclusion

With all these applications in mind, making the shift to automation and IIoT-based technology seems like the obvious choice. Thankfully, igus® has an extensive offering of smart plastic products for use in IIoT systems. e-chain® cable carriers, chainflex® cables, linear bearings and more, all outfitted with our smart plastic technology. Our smart plastic products are already used in a variety of applications, and we’re constantly expanding our offerings to meet the growing needs of our customers.

If you have any questions regarding smart plastics in use with our linear bearings, please contact our smart plastics drylin® expert here. For questions regarding smart plastics in use with our cable carriers and cables, please contact our smart plastics e-chain® expert here. You can also contact us by phone at (800) 965-2496. For more info about IIoT, check out our white paper!